In 2023, at the ITMA in Milan, Italy, the ChiuVention series of innovative instruments and the SmarTexLab intelligent textile laboratory system received a lot of attention from the industry’s benchmark brands such as Adidas, Decathlon, and related research institutes, universities, and standards organisations. ChiuVention has also received orders from various countries around the world (Adidas, Canada Goose, Decathlon, AEO (American Eagle), BV Bureau Veritas, ITS Tiangxiang, Nippon Spinning and Inspection, Deyonga Textile, etc.) ChiuVention has gained international recognition from the very first time it was launched.

In 2024, according to the market demand, ChiuVention has launched another series of intelligent textile testing instruments. The next step is to introduce ChiuVention’s latest on-line textile testing instruments.

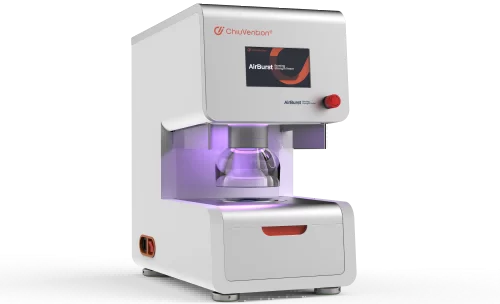

AirBurst Bursting Strength Tester

Bursting strength testers are usually categorized as hydraulic or pneumatic. This AirBurst pneumatictester tests the strength of textiles, films, paper, and foam. It has a simple structure, so it is easier to operate and maintain. HydroBurst hydraulic tester is for tests that need higher and more stable pressure.This includes tests on high-strength textiles and leather.

Principle of the AirBurst Bursting Strength Tester: clamps the sample on the diaphragm. It applies air pressure beneath the diaphragm. A high-precision sensor monitors the pressure in real-time. The control panel displays the pressure data. The air pressure will increase. The sample will eventually rupture. It will happen under a certain pressure. This pressure is the maximum atmospheric pressure at the moment of rupture. This pressure is the bursting strength of the sample. The instrument records and shows the value.

Four test modes are available: constant speed, constant pressure, constant dilatancy, and timed expansion. They can better show how much the sample resists expansion.

Precise and reliable testing.

The pressure measurement section uses a high-precision laser sensor. It has an accuracy of up to 0.2 degrees. This means the error is 0.2% of the maximum range.

Longer sensor life.

The Panasonic laser displacement sensor is also used. It has no rod, so it is easier to change the test cup and is hard to damage.

Connected to SmarTexLab, test results can be uploaded to ERP or LIMS.

The AirBurst can connect to the SmarTexLab App made by ChiuVention via Wi-Fi. This connection allows you to set parameters or watch the test from your phone. And the test results will also be sent to SmarTexLab and you can export

them to a computer or print them. Also, it can link to an organization’s ERP or LIMS to enable paperless and smart testing. All these things improve the textile laboratory’s quality management.

Intelligent Recognition System for Test Cups

When replacing the test cup for testing, the system will recognize the model of the current test cup. It will then switch the test parameters without manual input. This greatly improves work efficiency.

Eco-friendly and easy to maintain.

Using air as the pressure medium makes it eco-friendly and harmless.

The pneumatic tester has a simple structure. It’s easier to maintain and service than the hydraulic type.

Wide range of applications

It applies to the textile industry. This includes many common fabrics and non-woven fabrics. It also applies to packaging,materials, such as film, paper, and foam.

SmartDispen Detergent Dispenser

SmartDispen is a sample preparation device for washing color fastness tests. It can greatly improve the accuracy and efficiency of these tests. And it can weigh the fabric sample, add soap according to the bath ratio, and stir. It can also add water and dispense steel balls. It does this to prepare the samples for the washing fastness test. This all happens in one step. It reduces the error of manual operation and makes the test more reliable. It has three work stations. You can prepare three samples at one time.

It speeds up the sample preparation by 6 times. This makes washing color fastness tests faster.

Taking 24 test cups as an example. Traditional manual prep takes over 20 minutes. SmartDispen takes only 3. You can start the three stations together. They greatly speed up sample preparation. This lets the lab do more washing tests

each day.

More reliable testing

This machine has a high-precision balance that weighs automatically. SmartDispen can dispense the soap based on the bath ratio. Besides, it has exact temperature control. It also has a steel ball counting function. These features make

the sample preparation more accurate and the testing more reliable.

You can upload the data to ERP or LIMS.

The SmartDispen can connect to the SmarTexLab App by ChiuVention Team via Wi-Fi. You can set parameters, watch the test, and send sample prep info from the smartphone.

The data can also be uploaded to an enterprise’s ERP orLIMS. This will give the textile labs more complete colorfastness to wash data. So, they will have better management of textile quality.

SmartCrock Crockmeter

SmartCrock Crockmeter is used to test the color fastness of textiles or leather to dry or wet rubbing. In the test, a standard white rubbing cloth is rubbe drepeatedly against a sample at a certain speed. After the test, you can rate color fastness by comparing the color depth of the friction cloth with the standard grey card. They do this under a standard light.The rubbing color fastness tester is fully automatic. It repeats rubbing. The rubbing head can lift up and down on its own. The fixture can hold dry and wet samples at once. The loading table can be shifted left and right.This makes it easy to quickly do the dry and wet rubbing color fastness test. It reduces the influence of manual operation on the test results. What’s more, it saves 20% of the test time, and saves labor at the same time.

SmartCrock is applicable to ISO 105×12, GB/T 3920, AATCC8 ,ISO 20433 Method C and other standards, suitable for testing cotton, chemical fiber, blended and other colored fabrics and leather.

Fully automatic testing, efficient and reliable.

When you load the friction cloth and sample and press start,the friction head will land on the sample. It will then move it back and forth. Then, it will automatically stop and lift up after a set number of times. This reduces the influence of

manual operation on the test results. It also makes the test faster and more accurate.

Connected to SmarTexLab, the test results can be uploaded to ERP or LIMS.

The SmartCrock can connect to the SmartTexLab App by ChiuVention Team via Wi-Fi. This allows you to set parameters or track the test from your smart phone. And the test results will be seen in the SmartTexLab, besides, it can be uploaded to the company’s ERP or LIMS. This paperless and intelligent testing makes textile lab quality management easier and faster.

Wet and dry rub tests can be carried out quickly, saving 20% time.

You can hold wet and dry specimens at the same time. The removable loading table lets you quickly switch between the textile’s friction zones. You can perform dry and wet friction tests quickly.

Noiseless and durable.

Moving parts use linear guides. They make the instrument run smoothly and quietly. The main body of the sample table is made of durable aluminum alloy.

QuicExtra Fiber Oil Extractor

The QuicExtra Fiber Oil Extractor uses the principles of penetration and evaporation of solvents (e.g., petroleum ether, ethyl ether, or other organic solvents) to dissolve oils in fabric fibers. This method detects oil in wool and synthetic fibers.

The process is: cut the fabric into small pieces. Put the sample into the metal tube. Add the right amount of solvent. Ensure that the solvent and the sample are in full contact, which in turn dissolves the oils and fats. Put weights on the metal tube. This will speed up the dissolution and filtration of the oils and fats. It will let them separate from the sample. The solvent and oil will drip from the bottom of the tube onto the heating plate. The solvent will slowly evaporate, leaving only the oil. Finally, weigh the remaining oil. Then, divide it by the initial sample mass to find the oil amount.

Fast extraction, high efficiency and labor saving

QuicExtra is based on the principle of automatic weight pressurization. It uses weights, so manual pressure is not needed. Each of the 4 stations has its own operation buttons. They complete the extraction of fiber oils and fats in less than 10 minutes.

Thorough extraction and more accurately testing.

Adopting microcomputer temperature control, with good temperature uniformity. It ensures that the oil is extracted thoroughly and the test results are more accurate.

Intelligent operation, flexible and convenient.

It has a built-in 4-station timer and an independent oil calculator. It’s also convenient for operation and can transfer data to the cloud.

Connected to SmarTexLab, the test results can be uploaded to ERP or LIMS.

The QuicExtra Fiber Oil Extractor can connect to the SmartTexLab App by ChiuVention Team via Wi-Fi. This allows you to set parameters or track the test from your smart phone. And the test results will be seen in theSmartTexLab,

besides, it can be uploaded to the company’s ERP or LIMS.

This paperless and intelligent testing makes textile labquality management easier and faster.

SmartSnag ICI Mace Snag Tester

SmartSnag is used to test the degree of hooking (yarn pulls out of the fabric) under normal wear. It can test the hooking of outerwear knitted fabrics and other fabrics that are prone to hooking. This includes chemical fibers, filaments,

and their deformed yarn.

The test’s principle is this: set the cylinder-shape sample on the cylinder. Then, place a chain-hanging nail hammer on the sample. The cylinder rotates at a constant speed. The hammer is randomly flipped and jumped on thespecimen’s surface. This process causes the fabric to gradually produce hooks.

After a set number of rotations, the sample is taken down.We use a rating light box. Under the light, we compare the sample’s hooking degree with the standard hooking level photo. The anti-hooking level categorizes into 5 (no hooking) to 1 (serious). The instrument has Internet of Things (IoT) capabilities. It can connect via WIFI to SmarTexLab, an APP, to do smart testing.

Smart and faster testing

The instrument is connected via IoT to the SmarTexLab APP in the phone/PC. And The app can connect to ERP/ LIMS via an API. Or, the instrument can connect directly to ERP/LIMS. There are test orders and sample information in the system, and the instrument can start the test and record the sample info, test process, and test or rating results.

The system will then summarize these into a test report.

The report can be sent to SmarTexLab or ERP/LIMS.

The relevant parties can view the report in real time.

Test men can monitor tests for many instruments at once.

They can also change test requirements, get alerts before tests end, and stop or repeat tests remotely.

In SmarTexLab, you can set up programs to start or stop the instruments. You can chat with ChiuVention service staff for quick support. You’ll get reminders that instruments need calibration, maintenance, and new consumables. Regular OTA remote upgrades are available.

A fast hooking test and reliable results.

This ICI Mace Snag Tester runs fast and the rotation speed can be adjustable. The ball has tungsten carbide needles evenly distributed on it. They contact the specimen in 360 degrees. This realistically reproduces the hooking scenario and makes the test results more reliable.

Durable and low-noise

Precise and high-grade motor drive, smooth running, and low noise.

The whole shell and main structure are made of hard, rust-free, impact resistant oxidized aluminum alloy and stainless steel. They are still as good as new after many years.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: medium@chiuvention.com