Colour fastness to rubbing is one of the basic colour fastness tests among the many colour fastness tests for textile intrinsic quality indicators. The test standards of different countries have the same principle but different details. This paper compares and analyses the rubbing test methods of different countries, such as international, USA, Australia, Canada, Japan and China.

This article will analyse the results of the standard methods of 9 different organisations and countries for colour fastness to rubbing. In addition, some methods and recommendations for improving colour fastness to rubbing are presented.

Test Methods for Colour Fastness to Rubbing of Textiles

There are nine standard methods for colour fastness to rubbing from different organisations and countries presented in this post.

ISO 105— X12:2016 Textiles – Tests for colour fastness -Part X12: Colour fastness to rubbing

CAN/CGSB 4.2 No.22—2004 Textile test methods Colourfastness to rubbing (Crocking)

GB/T 3920—2008 Textiles-Tests for colour fastness-Colour fastness to rubbing

AS 2001.4.3—1995(R2016) Methods of test for textiles-Method 4.3: Colourfastness tests-Determination of colourfastness to rubbing

AATCC 8—2016 Colorfastness to Crocking: Crockmeter Method

JIS L0849:2013 Test methods for colour fastness to rubbing

ISO 105-X16:2016 Textiles – Tests for colour fastness -Part X16: Colour fastness to rubbing -Small areas

AATCC 116—2013 Colorfastness to Crocking: Rotary Vertical Crockmeter Method

GB/T 29865—2013 Textiles–Tests for colour fastness-Colour fastness to rubbing-Small areas

Differences in testing conditions

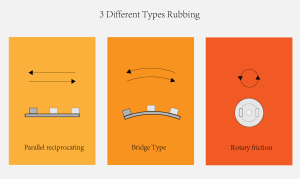

The rubbing colour fastness test is carried out on a rubbing colour fastness tester. In terms of rubbing method, there are three kinds of rubbing test methods: parallel reciprocating type, bridge type and rotating rubbing. Usually, the standard white cotton cloth for rubbing is fixed on the rubbing head, and under certain pressure, the dyed fabrics are rubbed according to the specified rubbing method, the number of rubbing times and the rubbing range to complete the test operation. Usually, the white friction cloth is used in both dry and wet conditions. After drying the friction fabric specimens, the degree of staining of the friction white fabrics is evaluated with a standard stained grey sample card under a quasi-light source. The test methods vary from country to country in terms of friction range and speed, friction head pressure and size, moisture content of the cloth and humidification method. These differences have an impact on the test results.

Friction range

Parallel reciprocating friction range is generally (104±3) mm or (103±5) mm. The bridge type is the Japanese standard for friction fastness, type II friction colour fastness tester, which has a reciprocating range of 100 mm. Rotational friction is fixed above the sample and rotates around the centre of the circle, and the contact surface is only the area of the circular friction head.

Friction speed and number of times

Reciprocating friction 60 times/min, i.e. 1 time per second, 10 times reciprocation, a total of 20s of friction;

Rotary friction 1 revolution / second, reciprocating 10 times, a total of 20s friction;

Bridge type friction 30 times/min, i.e. 1 time every 2 seconds, 100 times of reciprocation, a total of 200s friction.

Day standard friction is the highest number of times, and the longest friction time, is 10 times the reciprocating and rotating friction. Therefore, the longer friction course brings about more stringent testing, and the same textile is tested poorly by this method.

Friction head size and pressure

For reciprocating friction standards

American Standard AATCC 8-2013, Australian Standard AS 2001.4.3-1995, Canadian Standard CAN/CGSB-4.2 NO.22-2004 Cylindrical friction head diameter is (16±0.1)mm, area 203.5mm2, pressure is 9N. International standards ISO 105-X12:2001 and GB/ T 3920-2008, with two kinds of friction head, one is a square friction head size of 19mm*25.4mm, an area of 482.6mm2, and the other is a cylindrical friction head diameter of (16±0.1)mm, an area of 203.5 mm2, the pressure is 9N.

Friction standards for overbridge type

Japanese standard JIS L0849: 2013 friction head is more special 20*20mm square, surface radius of 45mm curved surface.

Rotary Friction Standard

International Standard ISO 105-X16:2001, American Standard AATCC 116-2013, Chinese National Standard GB/T 29865-2013, the friction head of these standards is also cylindrical friction head diameter (16±0.1) mm, area of 203.5 mm2, but the pressure is 11.1N. The pressure is 11.1N.

Sampling direction

Reciprocating friction standards, and bridge friction standards, in addition to the U.S. AATCC standard is 30°oblique sampling, the rest of the latitude and longitude to the respective sampling. Rotary friction standard for a small area of fixed origin friction, no need to cut the sample.

Moisture content

AATCC standards in the reciprocating friction and rotary friction are required for wet friction cloth moisture content of 65%.

The ISO and GB standards require a moisture content of 95% to 100%. However, if this moisture content seriously affects the grading, other moisture content can be used, such as the commonly used moisture content of (65±5)%. The CAN/CGSB standard, the AS standard and the JIS overbridge friction standard require a moisture content of 100%.

The higher the moisture content, the greater the degree of wetness of the wet friction cloth. Dyestuffs are usually easy to hydrolyse and lose colour when they are wet. Therefore, the higher the water content, the lower the colour fastness result of wet rubbing.

Factors affecting colour fastness test results

As can be seen from the relevant test data, the colour fastness to wet rubbing results between different methods differ by 0.5 to 1.5 levels, which is a large difference. Therefore, to judge the colour fastness of textiles to rubbing, it is necessary to choose the correct test method. The differences in wet rubbing fastness and their reasons are analysed below from several different angles.

Rotary type vs Reciprocating type

For monochrome printed fabrics, the colour fastness to wet rubbing of rotary rubbing is slightly higher than that of reciprocating rubbing by 0.5 to 1 level and higher than that of Japanese bridge rubbing by 1 to 1.5 levels. Therefore, for monochrome textile fabrics, the colour fastness of rotary rubbing is the best for small areas, reciprocating rubbing is in the middle, and Japanese bridge rubbing is the most stringent and has the worst results.

In rotary rubbing, although the hammer pressure is slightly larger, the number of rubbing in the same case, because it is in the same small area of circular position for rubbing, rubbing cloth and fabric contact area is much smaller than the reciprocating rubbing of the contact area of the fabric. Therefore, the staining of the colour is less, so the rotary friction colour fastness is better than the results of reciprocating friction colour fastness.

The Japanese test standard is 100 times of reciprocating friction, while other reciprocating friction is only 10 times, which is a huge difference. Therefore, the total contact area and the total course of the Japanese standard friction test should be long, so the friction colour fastness test results are the worst, and the test method is the most stringent in the above 8 standards.

Different shapes of friction heads

A comparison of the wet rubbing test results for different rubbing heads from ISO 105-X12:2001 and GB/T 3920-2008 shows that the shape of the rubbing head also has a direct influence on the results in reciprocating rubbing. The colour fastness to wet rubbing of square rubbing heads is the same or slightly better than the colour fastness to wet rubbing of round rubbing heads by half a degree.

A comparison of the reciprocating friction test methods shows that the reciprocating friction methods of several countries have the same hammer pressure of 9N, the same reciprocating stroke of (103±5) mm or (104±3) mm and the same number of rubs. But in addition, the friction head of the different directly manifested in the friction head bottom area is different, the fabric in the friction process of the different degrees of force. The area of the square head is 482.6mm2 which is larger than the area of the round head is 203.5mm2, so the pressure of the friction of the square head is smaller than the friction of the round head. Therefore, in the case of wet friction with the same moisture content of the cloth, the colour fastness of wet friction obtained by the square rubbing head is slightly lighter, but the difference in colour fastness between the result and that of the round rubbing head is not more than half a grade.

For loop pile products, considering that the test results of different shapes of friction heads are less different, and the round friction head is easy to produce side slipping in the friction process, the international ISO standard and the Chinese GB standard are not suitable for this product. Therefore, the ISO standard and GB national standard require the use of a square-shaped rubbing head for the colour fastness test of loop pile products.

Sampling direction

In reciprocating friction, with the same rounded friction head and 100% moisture content of the wet friction cloth, the results show that the AATCC AFSL test results for oblique sampling are consistent with or slightly better than half a level of the test results along the warp and weft directions.

This may be mainly because the friction between the friction head and the tissue yarns during friction at an angle of 30˚is slightly less than that when it is perpendicular to the friction between the friction head and the warp and weft yarns in the diagonal direction. Therefore, the rubbing results of the oblique angle sampling method are slightly better by half a degree or more consistent.

Moisture content

The AATCC standard wet rubbing results for rounded and diagonal are slightly better than the International Standard and the GB warp and weft, contrary to the pattern analysed above. This is mainly because the water content of the AATCC standard is 65%, whereas the GB and ISO standards are 100%, which is a big difference between the two conditions, so the wet rubbing fastness of the American standard with a smaller water content is better. It appears that the moisture content has a greater influence on the rubbing fastness results than the direction of sampling, which ultimately affects the results.

The need for warp and weft testing

The difference between the results of the warp and weft tests is because the organisational closeness of the fabrics is often different in the warp and weft directions. The friction force and the total colour contact between the fabric and the textile during friction are therefore different. This leads to differences in friction results in both directions, which is why it is important and necessary to test in both the warp and weft directions in some test standards.

Small coloured textiles

For monochrome textiles, we know from the previous tests that the colour fastness to wet rubbing of rotary rubbing is slightly higher than that of reciprocating rubbing by 0.5~1 level, and higher than that of wet rubbing of Japanese bridge type by 1~1.5 levels. Therefore, the colour fastness of rotary rubbing is the best for small areas, reciprocating rubbing is in the middle, and Japanese over-the-horizon rubbing is the most stringent with the worst result.

For coloured fabrics and printed fabrics, due to the small colour surface area, if reciprocating rubbing is used, different colours will be mixed and stained on the rubbing cloth during the rubbing process. In addition to the complexity of the rating, the different colour fastnesses between the colours, as well as the differences in colour shades, all have an impact on the results. This is also the main reason for differences in the testing of coloured fabrics and prints between laboratories, as it is not possible to take identical samples from different laboratories. When using reciprocating friction, the difference between different laboratories is due to different sampling positions, friction mixing of colours, and the final colour fastness given will also be different.

International standards, American standards, and China’s national standards have a special small area rubbing colour fastness test standard method, the provisions of the rotary method for colour woven fabrics, printed fabrics, and a single small block of colour for separate testing. However, many customers and buyers are not clear about the difference between these, so usually still require the reciprocating friction method, which is not very accurate for the actual colour fastness requirements and control of the product.

Methods to improve the colour fastness to rubbing

- Appropriate pre-treatment of fabrics before dyeing, such as mercerising, burnishing, cellulase finishing treatment, boiling, bleaching, washing and drying, can improve the surface finish and gross effect of fabrics, reduce friction resistance and improve the fibre’s ability to absorb dyes.

- In the textile post-treatment, the fabric is fully soaped and washed to clean the floating colour on the surface of the fabric.

- Polyester fibre dyed with dispersed dyestuff after high-temperature fixing will lead to dye swimming to the surface of the fibre, causing a decrease in the colour’s fastness to rubbing. Adding a fixing agent or smoothing agent can improve the colour fastness to rubbing to a certain extent.