Basic Concepts of Textile Air Permeability Test and Moisture Permeability Test

Textile air permeability testing and moisture permeability testing are two different test methods. Although both tests are related to the breathability of textiles, their purposes and test methods are quite different. Let’s take a look at the basic concepts of these two tests.

First, textile Air Permeability Testing is used to measure the ability of a textile to allow air to pass through. This type of test is often used to evaluate sportswear, outdoor equipment, and other textiles that require good ventilation. The results of an Air Permeability test are usually expressed in terms of airflow per square meter per second. This means that if a textile has a breathability test result of 100 cubic meters per square meter per second, then 100 cubic meters of air can pass through each square meter of textile every second.

On the other hand, a textile moisture permeability test is used to measure the ability of a textile to allow the passage of water vapor. This type of test is commonly used to evaluate waterproof clothing, raincoats, and other textiles that need to be waterproof but still breathable. The results of a moisture permeability test are usually expressed in grams per square meter/24 hours. This means that if a textile has a moisture permeability test result of 500 g/m2/24 hours, then 500 grams of water vapor can pass through each square meter of textile every 24 hours.

Now, you may think these two tests sound similar, so what are the differences between them? Well, let me tell you that the difference lies in the medium of the test. The air permeability test uses air as the medium, while the moisture permeability test uses water vapor as the medium. This means that even if a textile has a good air permeability test result, it may have a poor moisture permeability test result and vice versa.

In addition, the test methods for air permeability and moisture permeability tests are different. Air Permeability Tests typically use a fan or compressed air to simulate air movement, while moisture permeability tests use a humidity control device to simulate water vapor transport. This means that even though both tests are conducted in a laboratory environment, the conditions and test principles are quite different.

In summary, textile air permeability testing and moisture permeability testing are two different test methods and can test the different properties of textiles. Air permeability testing is used to assess the ability of textiles to allow the passage of air, while moisture permeability testing is used to assess the ability of textiles to allow the passage of water vapor. In other words, the air permeability test is about the circulation of air, while the moisture permeability test is about the expulsion of water.

Importance and Application of Textile Permeability Testing

Air Permeability Testing is a very important process that helps us to understand the breathability of textiles. Air Permeability is essential for maintaining human comfort. If you wear clothing that doesn’t breathe, you may feel stuffy and uncomfortable, like you’re locked in a room with no air conditioning. Therefore, Air Permeability testing is very important for manufacturers to help them ensure that their products provide good breathability.

Air Permeability Testing is used in a wide range of applications, such as the apparel industry, home textiles, medical supplies, sports equipment, and other fields. For example, in the medical field, Air Permeability Testing can help manufacturers ensure that their products provide sufficient breathability to prevent the spread of bacteria and viruses. In sports equipment, Air Permeability Testing helps manufacturers ensure that their products keep athletes’ bodies dry and comfortable during exercise.

In addition, the Air Permeability Test can help manufacturers improve their product designs. By testing different materials, manufacturers can find the most suitable breathability for their products. This not only improves the quality of the product but also increases consumer satisfaction.

So, the next time you put on a comfortable and breathable piece of clothing, thank the hard-working textile testers who ensure your clothes don’t make you feel like you’re being held in a steamer.

Importance and Application of Textile Moisture Permeability Testing

Moisture Permeability Testing for Textiles is also a very important test program that helps us to understand the breathability of textiles. This test is vital for garments that need to keep the body dry and comfortable, such as sportswear, outdoor clothing, and workwear.

Firstly, moisture permeability testing can help us understand the waterproof performance of textiles. Water repellency is the ability of a textile to stop the passage of moisture, which is very important for those who need to work or move around in a humid environment. If a textile is not waterproof, the person wearing it may feel wet and uncomfortable. Therefore, moisture permeability testing can help us choose textiles are better suited to our needs.

Then, moisture permeability testing can also help us understand the warmth retention properties of textiles. Warmth retention refers to the ability of textiles to maintain body temperature, which is very important for those who need to work or move in cold environments. If a textile does not retain warmth well, the person wearing it may feel cold and uncomfortable.

Overall, the textile moisture permeability test is an important test program that can help us understand the breathability, water resistance, and warmth retention of textiles. This test is crucial for those garments that need to keep the body dry and comfortable. Therefore, if you are looking for textiles that are comfortable for consumers, then the moisture permeability test is a test program that you cannot afford to ignore.

Test Methods and Criteria for Textile Air and Moisture Permeability Testing

First, let’s look at the methods and criteria for testing textile air permeability. Air permeability testing is usually carried out using a device called an air permeability tester, also named air tightness testing equipment. This air permeability test apparatus measures the flow of air through a textile at a certain pressure for a certain period. The test results are usually expressed in terms of airflow per square meter per second. There are many air permeability test standards for air permeability testing machines, such as ASTM D737 and ISO 9237, GB/T 5453. These standards specify the specific conditions of the test, such as test pressure, test time, and test area.

Next, let’s look at the methods and standards for textile moisture permeability testing. Moisture permeability testing is usually carried out using a device called a water vapor permeability tester. This equipment measures the amount of water vapor that passes through the textile over a certain period at a certain temperature and humidity. The test results are usually expressed in terms of water vapor transmission per square meter per 24 hours. There are also many standards for moisture vapor transmission testing, such as ASTM E96 and ISO 11092, JIS L1099. These standards specify the specific conditions of the test, such as test temperature, test humidity, and test time.

It is worth mentioning that although air permeability and moisture permeability tests are two different test items, they are closely related to each other. Generally speaking, a textile with good air permeability will also have better moisture permeability, because both air and water vapor needs to pass through the pores of the textile. However, this does not mean that air permeability and moisture permeability are identical. Some textiles may be very breathable but have poor moisture permeability and vice versa. Therefore, when assessing the comfort and functionality of textiles, we need to consider both.

Introduction to Instruments and Equipment for Textile Air Permeability and Moisture Permeability Testing

First, let’s look at air permeability testing. Air permeability meter is used to assess a textile’s ability to transmit air, i.e. it measures how quickly air can pass through the textile. This test is important for textiles that need to remain ventilated, such as sportswear and outdoor equipment. The air permeability tester for textiles usually consists of a fan and a manometer, which measure the speed at which air passes through the textile at a given pressure.

Next, let’s look at moisture permeability testing. Moisture permeability testing is used to evaluate a textile’s ability to transmit water vapor, i.e., it measures how quickly water vapor can pass through the textile. This test is important for textiles that need to stay dry, such as raincoats and waterproof shoes. The instrumentation used for moisture permeability testing usually consists of a hygrometer and a thermometer, which measure how quickly water vapor passes through a textile at a certain temperature and humidity.

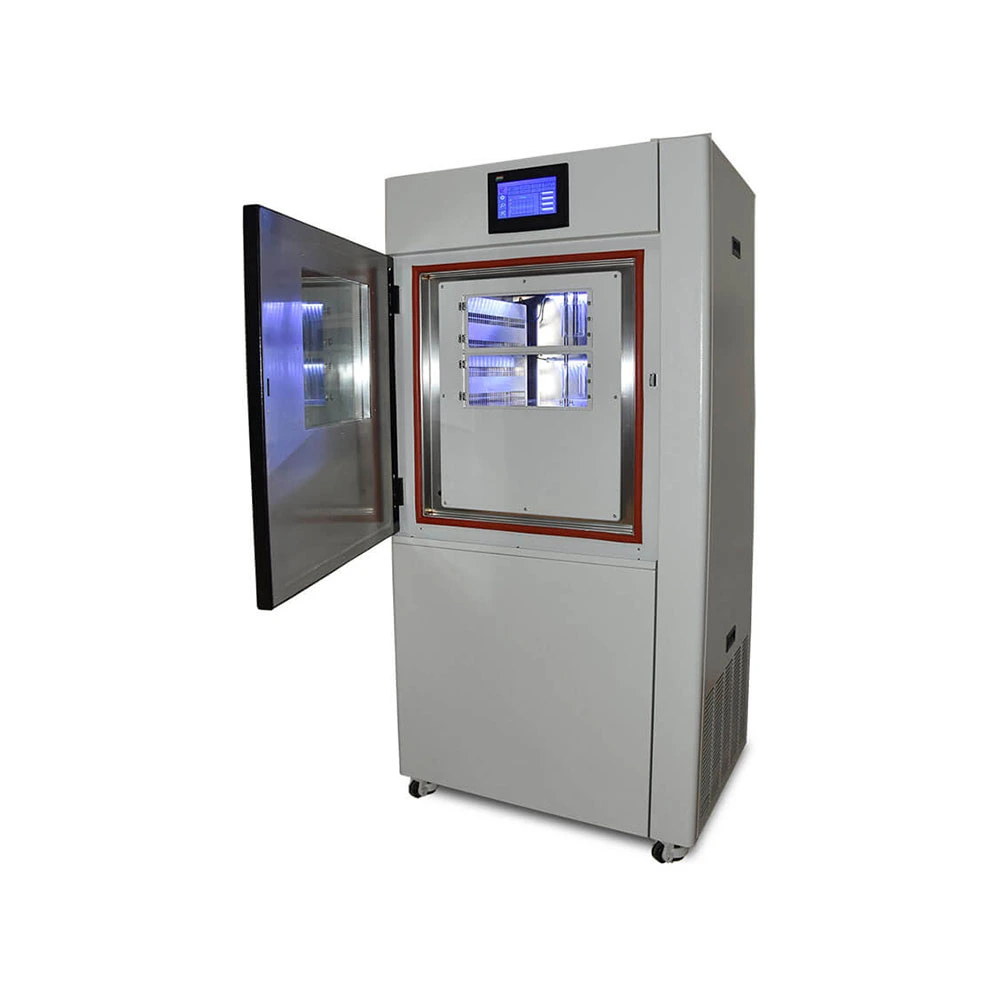

So how do you differentiate between breathability and moisture permeability testing? It’s quite simple, just remember that air permeability testing is for air, while moisture permeability testing is for water vapor. In addition, the instrumentation for air permeability testing is usually relatively simple, whereas the instrumentation for moisture permeability testing is relatively complex as it needs to simulate the temperature and humidity of the human body. Except for its working principle, the prices between them are also different. Air permeability tester prices and water vapor testing machine prices vary in different brands with different functions. Get a quick quote on an air permeability tester for textiles in the picture below.

Common Problems and Solutions for Textile Air Permeability and Moisture Permeability Testing

Textile air permeability and moisture permeability tests are two very important tests that are essential for assessing the performance and comfort of textiles. However, they are often confused, resulting in inaccurate test results. It is therefore important to understand the difference between them and how to perform the tests correctly.

First, let’s look at the air permeability test of fabric. The breathability test is used to evaluate the ability of a textile to allow air to pass through. This test is important for textiles that need to stay ventilated, such as sportswear and outdoor gear. However, a common problem is that air permeability tester for the fabric used for the test is not set up correctly, resulting in inaccurate test results. To solve this problem, testers need to ensure that the instrument is set up in accordance with the requirements of the standard and that it is calibrated before and after the test.

Next, let’s look at moisture permeability testing. Moisture permeability testing is used to evaluate the ability of a textile to allow water vapor to pass through. This test is important for textiles that need to stay dry, such as raincoats and waterproof shoes. However, a common problem is that the temperature and humidity of the testing environment do not meet the requirements of the standard, resulting in inaccurate test results. To solve this problem, testers need to ensure that the temperature and humidity of the testing environment meets the standard requirements and is monitored before and after the test.

Another common problem is that testers confuse air permeability and moisture permeability testing. While these two tests may sound similar, they actually evaluate different aspects of a textile’s performance. The air permeability test is concerned with the circulation of air, while the moisture permeability test is concerned with the circulation of water vapor. Therefore, testers need to clearly distinguish between the two tests and use the correct test method.

Finally, to ensure the accuracy of the test results, testers need to maintain and calibrate the test equipment on a regular basis. This ensures that the performance of the test equipment is always in the best condition, thus improving the accuracy of the test results.

In conclusion, textile air permeability and moisture permeability testing are two very important tests that are essential for assessing the performance and comfort of textiles. However, these two test programs are often confused, resulting in inaccurate test results. To solve this problem, testers need to ensure that instruments are set up according to standard requirements and calibrated before and after testing. In addition, testers need to clearly distinguish between the two tests and use the correct test method.

Textile Air and Moisture Permeability Testing in Outdoor Sports Clothing

Now, let’s take a look at how these two tests are used in outdoor sports apparel. Manufacturers often design their products based on the results of breathability and moisture permeability tests. For example, if an outdoor sports garment has good breathability test results, then it may be designed to be worn in hot weather. Conversely, if an outdoor sports garment tests well for moisture permeability, it may be designed to be worn in humid weather.

In conclusion, textile air permeability and moisture permeability testing are very important in outdoor sports apparel. Both tests can help manufacturers design products that are more comfortable and drier, thus enhancing the wearer’s outdoor sports experience. So the next time you’re picking out outdoor sports apparel, pay more attention to their breathability and moisture permeability test results then you can find the best product for you.

Application of Textile Air Permeability and Moisture Permeability Testing in Medical Protective Clothing

Now, let’s take a look at how these two tests are used in medical protective clothing. First, breathability testing can help manufacturers design protective clothing that provides adequate protection while remaining comfortable. This means that healthcare workers won’t feel uncomfortable wearing stuffy protective clothing in stressful work environments. Additionally, moisture permeability testing ensures that protective clothing blocks viruses and bacteria while still being able to wick away sweat, preventing the development of eczema and other skin problems.

So, how are these two tests performed? Air permeability testing is usually done by measuring the flow of air through a textile over a certain period of time. Moisture permeability tests, on the other hand, are conducted by measuring the amount of water vapor that passes through the textile over a certain period of time. Both tests require specialized equipment and technicians.

Overall, air permeability and moisture permeability tests play an important role in the field of medical protective clothing. Not only do they help manufacturers design more comfortable and safer protective clothing, but they also ensure that healthcare workers stay dry and comfortable on the job. So, the next time you see a healthcare worker wearing protective clothing, think about how important the breathability and moisture permeability testing behind these suits is.

For more information on textile testing methods/standards

or textile testing machines, please contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com