1、Related standards for the determination of breaking strength of textiles at home and abroad

The breaking strength of a textile is the tensile breaking strength, which is the force required when the textile is stretched directly by an external force to break. It is an indicator of the absolute value of the tensile force, and the legal unit is Nm (N). In the determination of the breaking strength of textiles, the breaking strength force refers to the maximum force of the specimen being pulled off during the tensile test under specified conditions.

The breaking strength is usually used to evaluate the effect of sunlight, washing, abrasion, and various finishes on the inherent quality of the fabric. Therefore, textiles with anisotropic mechanical properties and small tensile deformation capacity are tested for this property. At present, there are two main methods for determining the breaking strength of textiles, namely, the strip sample method and the grasping sample method. The relevant standards for the determination of the breaking strength of textiles at home and abroad are shown in Table 3-1.

Table 3-1 Domestic and international standards for determination of breaking strength of textiles

| Testing Method | Domestic Standards | Major foreign standards |

| Strip sampling method | GB/T 3923.1-1997, FZ/T 60026-1999 | ISO 13934-1:1999, ISO 13935-1: 1999, ISO 4606: 1995, ASTM D5035 (1995) BS 2576-86(95), DIN 53857.1-1979, DIN EN ISO 1393-1:1994,DIN ENISO 13934-2:1994, NFG 07-001-1973,EN ISO 13934-1:1999 etc. |

| Grab sampling method | GB/T 3923.2-1998 | ISO 13934-2:1999,ISO 13935-2:1999, ASTM D5034(1995),DIN53858-1979,NFG 07-120-1973,EN ISO 13934-2:1999 etc. |

2、Comparison of domestic and foreign textile breaking strength test methods

2.1 Strip sample method

The strip sample method can measure the breaking strength of the specimen over the whole working width and can analyze the adequate strength of the yarn in the fabric, and compare it with the power of the yarn before weaving, so the method is most commonly used. The main technical parameters of the strip test vary between domestic and international standards, see Table 3-2.

GB/T 3923.1-1997 test methods and procedures are described below.

(1)Specimen preparation In more than 150mm from the edge of the cloth, cut two groups of specimens, one group of warp specimens, and the other group of weft specimens. For each group of 5 pieces, the effective width of each specimen is 50mm (excluding the raw edge), and the length should be able to meet the requirements of the separation distance of 200mm.

Table 3-2 The main technical parameters of the strip sample test

| Projects | GB/T 3923.1-1997 | ISO 13934-1 | ASTM D5035 |

| Test Range | Suitable for woven fabrics, also suitable for knitted fabrics, coated fabrics, and other types of textile fabrics | Suitable for woven fabrics, but also for fabrics produced by other technologies

| Suitable for woven fabrics, not recommended for knitted fabrics and high stretch fabrics (>11%) |

| Equipment | CRE Tensile strength tester | ||

| Upper and lower fixture spacing | 100mm or 200mm, accuracy ±1mm | 100mm or 200mm (depending on the elongation value) | 75mm

|

| Tensile rate | 20mm/min or 100mm/min, accuracy ±10% | 20mm/min, or 100mm/min (depending on elongation value) | 300mm/min

|

| Environmental conditions | Temperature (20±2)℃, relative humidity (65±2)% | Temperature (20±2)℃, relative humidity (65±2)% | Temperature (21±1)℃, relative humidity (65±2)% |

| Humidification time | At least 4h | 24h | At least 4h |

| Specimen size | Length at least 200mm or 100mm, width (50±2) mm (trimmed edge yarn layer) | Length 300mm, Width 50mm | Length 250mm or 150mm width 25mm |

| Number of specimens | 5 pieces in the longitudinal direction, 5 pieces in the latitudinal direction | 5 pieces in the longitudinal direction, 5 pieces in the latitudinal direction | 5 pieces in the longitudinal direction, 8 pieces in the latitudinal direction |

If the elongation at the break of the specimen exceeds 75%, a separation length of 100 mm should be met.

The specimens should be evenly distributed on the sample, not containing the same warp and weft yarns between the specimens, and the length direction is parallel to the direction to be tested. Take the specimen and put it into the constant temperature and humidity laboratory for moisture conditioning before testing.

(2) check the calibration instrument, and set the test parameters If the fabric elongation at break <8%, the separation length is set to 200mm, and the stretching rate is set to 20mm/min; if the fabric elongation at break is 8%~75%, the separation length is set to 200mm, the stretching rate is set to 100mm/min; if the fabric elongation at break >75%, the separation length is set to 100mm and the stretching rate is set to 100mm/min.

(3) clamping specimen in the center of the clamp position, to ensure that the center line of tension through the midpoint of the clamp. The specimen can be clamped under top tension or loose clamping. The added top tension value should be determined according to the unit area mass of the fabric. Fabric unit area mass <200g / m², pre-tensioned value 2N; fabric unit area mass of 200 ~ 500g / m², pre-tensioned value 5N; fabric Unit area mass > 500g / m², pre-tensioning value of 10N.

(4) start the tensile tester, tensile strength determination stretch the specimen to fracture, and record the breaking strength, elongation at break or elongation at break. Test at least 5 pieces in each direction.

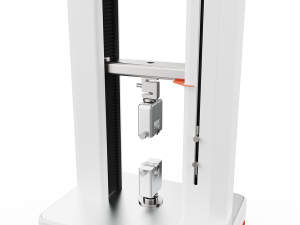

SmartPull Tensile Tester

If the specimen breaks within 5 mm from the jaws, it is considered jaw breakage. When 5 specimens are tested, if the jaw fracture value is greater than the smallest “normal value”, can be retained; if less than the smallest “normal value”, it is discarded, plus the amount of test to get 5 “normal “fracture value. If all test results are jaw fracture, or can not get 5 “normal value”, should be reported as a single value.

2.2 Grab sample method

The grab sample method is applicable to the fabric which is not easy to remove the edge yarn, high density, heavy pulp, coating, and the fabric which will produce the waist phenomenon with the strip sample method. The main technical parameters of the grasping sample method test domestic and foreign testing standards vary, see Table 3-3.

Table 3-3 The main technical parameters of the grab sample test

Projects | GB/T 3923.1-1998 | ISO 13934-2 | ASTM D5034 |

| Test Range | Suitable for woven fabrics, also suitable for knitted fabrics, coated fabrics, and other types of textile fabrics | Suitable for woven fabrics, also suitable for knitted fabrics, coated fabrics, and other types of textile fabrics | Suitable for almost all organic fabric strength tests, high elasticity fabric (more than 11%) is recommended not to use |

| Equipment | CRE Tensile strength tester | ||

| Upper and lower fixture spacing | (100±1)mm

| (100±1)mm or(75±1)mm | (75±1)mm |

| Tensile rate | (50±5)mm /min | 50mm/min | 300mm/min

|

| Environmental conditions | Temperature (20±2)℃, relative humidity (65±2)% | Temperature (20±2)℃, relative humidity (65±2)% | Temperature (21±1)℃, relative humidity (65±2)% |

| Humidification time | At least 4h | 24h | At least 4h |

| Specimen size | Length at least 150mm, width(100±2)mm | Length 200mm, Width 100mm | Length 150mm, Width 100mm |

| Number of specimens | 5 pieces in the longitudinal direction, 5 pieces in the latitudinal direction | 5 pieces in the longitudinal direction, 5 pieces in the latitudinal direction | 5 pieces in the longitudinal direction, 8 pieces in the latitudinal direction |

GB / T 3923.2-1997 test methods and procedures are described below.

(1) Specimen preparation in more than 150mm from the edge of the cloth cut two groups of specimens, a group of warp specimens, and the other group of weft specimens. Each group of 5 specimens is at least 150mm long and (100±2)mm wide, and the specimens are placed in a constant temperature and humidity laboratory for moisture conditioning and testing.

(2) Check the calibration of the instrument and set the test parameters. The spacing length is (100±1)mm and the stretching rate is (50±5)mm/min.

(3) Clamp the sample When clamping the sample, attention should be paid to the middle part of the sample, to ensure that the longitudinal centerline of the sample through the centerline of the clamp, and perpendicular to the clamp jaw line. The specimen should not be tilted, and the upper and lower exposed parts should be consistent.

(4) tensile strength determination Start the tensile tester, stretch the specimen to fracture, and record the fracture strength value. Pay attention to the observation when stretching, if some parts of the yarn of the tensile specimen break, the test should be stopped.

SmartPull Tensile Tester

If the specimen breaks within 5 mm from the jaw, it is regarded as a jaw break. When 5 specimens are tested, if the jaw break value is greater than the minimum “normal” break value, it can be retained; if it is less than the minimum “normal” break value, it is discarded and another test amount is added to get 5 “normal “fracture value. If all test results are jaw fractures, or can not get 5 “normal” fracture values, should be reported as a single value.

3、 Textile tensile breaking strength testing

3.1 Textile strip method of tensile performance test method differences

Europe and the United States and other countries and regions on China’s textile restrictions seriously affect and restrict the development of China’s textile industry, and one of the reasons for textile restrictions is that the product performance does not meet the requirements due to the differences in testing standards. Therefore, we must be in line with international standards in product standards, so that China’s textile standards from production-based standards into trade-based standards.

Fabric tensile properties are one of the most common textile performance test items in the textile trade, it is usually expressed by the breaking strength and elongation at break, used to characterize the maximum force and the corresponding elongation of the specimen when the fabric is stretched until it breaks during the tensile test under the specified conditions.

Fabric tensile properties of the test method There are two: the strip sample method and the grab sample method. The strip sample method test results of the uneven rate are smaller, with the cloth saving, so more commonly used. The strip sample method to determine the fabric breaking strength and elongation at break is under the specified pre-tension, the specimen is clamped to the isometric elongation tester, with a certain rate of stretching the specimen, record the maximum force and elongation when the specimen is pulled off.

3.1.1 The main differences in the determination of textile tensile properties of the strip sample method

(1) GB / T 3923.1-1997 “textile fabric tensile properties 1: the determination of breaking strength and elongation at break strip method” GB / T3923.1-1997 standard is a reference to the draft international standard ISO / DIS 13934-1: 1994 “textile fabric tensile properties Part 1 Part: Determination of maximum strength and elongation at maximum strength strip method”, the national standard GB/T 3923-1983 “Determination of breaking strength and breaking elongation of woven fabrics (strip method)” was revised. The scope of application of the standard, the use of apparatus, the preparation and clamping method of the specimen, the length of the set spacing, the stretching rate and the preload tension are clearly defined. The provisions of the spacing and stretching rate are shown in Table 3-4. The preload tension is based on the mass of the specimen unit area, not more than 200g/m² for 2N, 200 ~ 500g/m² for 5N, and 500g/m² for 10N.

Table 3-4 GB/T 3923.1-1997 specified spacing and stretching rate

| Elongation at break of the fabric/% | spacing/mm | Tensile rate/(mm/min) | Elongation rate/(%/min) |

| <8 | 200±1 | 20 | 10 |

| 8~75 | 200±1 | 100 | 50 |

| >75 | 200±1 | 100 | 100 |

(2) ISO13934-1:1999 “Tensile properties of textile fabrics Ⅰ: determination of breaking strength and elongation at break strip method” This standard and GB/T 3923.1-1997 standard in the spacing settings, stretching rate, sample preparation, and preload tension provisions are basically the same.

The main differences are the following two points:

①Scope of application.GB/T 3923.1-1997 standard applies to woven fabrics, but also to other technical production of materials, such as knitted fabrics, nonwovens, coated fabrics, and other types of textile fabrics; and ISO 13934-1:1999 standard does not apply to nonwoven, coated materials.

②The experimental results of the modification. There are some differences between GB/T 3923.1-1997 and ISO 13934-1:1999 in the requirements for modifying experimental results, as shown in Table 3-5.

Table 3-5 Modification requirements for experimental results of the two standards

| GB/T 3923.1-1997 | ISO 13934-1:1999 | ||

| Power/N | Amendment interval/N | Power/N | Amendment interval/N |

| Below 10 | 0.1 | Under 100 | 1 |

| 10~1000 | 1 | 100~1000 | 10 |

| 1000 or more | 10 | 1000 or more | 100 |

(3)ASTM D5035 (1995) “standard test method for fabric breaking strength and elongation at break (strip sample method)” ASTMD5035 (1995) standard applies to woven fabrics, knitted fabrics, and elasticity greater than 11% of the high elasticity fabrics are not recommended. The main difference between this standard and the above two standards is shown in Table 3-6.

Table 3-6 The main differences between the three standards

| Projects | ISO 13934-1 or GB/T 3923.1 | ASTM D5035 |

| Distance between upper and lower clamps/mm | 100 or 200 | 75±1 |

| Test Rate/(mm/min) | 20 or 100 | 300±10 |

| Size of front gripper rubbers/mm | 25X75 | 25X75(50) |

| Size of the rear gripper rubber/mm | 25X75 | 25X75(50) |

| Environmental conditions | (20±2)℃,RH(65±2)% | (21±1)℃,RH(65±2)% |

| Humidification time | 24h to constant weight | At least 4h to constant weight |

| Number of specimens/block | Warp 5 | Warp 5 |

| Latitude 5 | Latitude 8 | |

| Specimen size/mm | 300X50 | 150X50(25) |

3.1.2 Conclusion

There are differences in the technical content of the three testing standards regarding spacer size, tensile rate, moisture conditioning time, and specimen size. Therefore, if there are requirements on fabric strength in textile import and export trade, both sides of the trade should pay special attention to whether the testing method required by the other side is the Chinese standard, the American Society for Testing and Materials standard, or other international standards.