The Martindale Abrasion Test is one of the important methods to evaluate the durability of fabrics. Its test principle is to rub the fabric sample with a known abrasive under low pressure in a continuously changing direction, and compare the amount of abrasion or pilling with the standard parameters to compare. The significance and value of this martindale abrasion test method are mainly reflected in the following aspects:

Guarantee product quality and consumer interests: Through the Martindale abrasion Test, the abrasion resistance and pilling resistance in fabrics can be evaluated, thus effectively guaranteeing product quality and consumer interests.

Reduce production costs and waste of resources: Through the Martindale abrasion test, production costs and waste of resources, such as replacement, repair, scrapping, etc., can be avoided due to undurable fabrics.

Improve corporate competitiveness and brand image: Passing the Martindale rub test can improve corporate competitiveness and brand image, to better meet consumer needs and market changes.

Meet the requirements of relevant standards: such as the international standard ISO 12944, the domestic standard FZ/T 01053, etc., have stipulated the abrasion resistance and pilling resistance of the fabric, and the Martindale fabric abrasion resistance test can meet the requirements of these standards.

In conclusion, the Martindale fabric abrasion Test is an economical, simple and efficient fabric durability evaluation tool, which is essential for ensuring product quality and consumer interests, reducing production costs and waste of resources, enhancing corporate competitiveness and brand image, and meeting relevant Standard requirements and other aspects are of great significance and value.

Testing Procedures of Martindale Pilling and Abrasion Tester

- Prepare the sample: Cut out a sample of uniform size from the fabric sample, usually four samples need to be tested.

- Install the sample: Install the sample flatly on the Martindale Abrasion Tester, make sure that the sample is attached to the base of the instrument, and fix the sample with a suitable clamp.

- Determine the test conditions: According to the relevant standards or experimental requirements, determine the test conditions, including friction times, friction speed, load, etc.

- Overview of Martindale abrasion test methods

4.1 Under the known pressure, change the sample mounted on the sample holder and the standard friction cloth from a straight line to a gradually larger ellipse, and on the contrary

The direction of the fabric becomes a straight line again, and then the geometric figures running along the trajectory rub against each other to measure and evaluate the abrasion resistance in textiles. There are many evaluation methods for abrasion resistance.

- Significance and usage

5.1 Acceptance Experiments—This test method is not intended for acceptance experiments in commercial deliveries. Inter-laboratory testing is less precise, and due to the nature of abrasion testing itself, the reproducibility of results within and between laboratories using the same instrument on the same fabric is also poor.

5.1.1 When the buyer and the seller use this method to test and get inconsistent results, both parties should conduct a comparative test to confirm whether there is any statistical deviation between the results. It is recommended to use a professional statistical assistant to analyze the deviations. Both parties should select at least one group as similar as possible from the samples with problems.

similar samples. The samples were randomly distributed to two laboratories in equal amounts. Both parties should choose an acceptable probability level before the test, and the unpaired results of the two parties’ experiments after the test should be analyzed using the Student’s T-test. If a deviation occurs, or find out the cause of the deviation and correct it, or the buyer and seller interpret subsequent data in terms of known biases.

5.2 Abrasion resistance in textiles is largely affected by the test conditions, such as the properties of the abrasive, the trajectory of the friction, the tension on the sample, the pressure between the sample and the abrasive, the dimensional change of the sample, etc.

5.3 In certain tests, changing the abrasive can affect the fabric abrasion resistance. Abrasives must be replaced at regular intervals or viewed according to certain standard periods. For disposable abrasives, they can only be used once, or replaced after a certain number of uses. For permanent abrasives, they do not need to be replaced in a specific series of tests, but it is obvious that different laboratories have different replacement cycles due to different frequency of use. Durable abrasives are also replaced due to exposure to textile finishes or other substances and must be cleaned periodically. degree of wear and tear

Will be affected by the rating, and the judgment of the operator will also affect the test results.

Smartindale Martindale abrasion and pilling has a wide selection of test stations: CV210-9 type for 9, 6, 4 stations, CV210-6 and CV210-4 for 6 and 4 test stations separately. All of them can run with 3 speeds, slow (24rpm), normal (47.5rpm), and fast (75rpm), which can be adapted to a wide range of test methods and standards. Get martindale abrasion tester price today!

5.4 Measuring the abrasion resistance in textile materials with laboratory instruments is only one of many factors that affect the wear resistance of actual wear. “Abrasion Resistance”

(usually expressed in terms of the number of times a machine rubs, using a specific technique to achieve a specific amount of wear) and “durability” (defined as the ability to resist twisting and wearing in actual use, including the effects of friction) are often related, and between them The relationship between varies with different end uses, according to the number of friction

Various factors should be considered when estimating the textile abrasion test.

5.4.1 When the laboratory test data of different materials are quite different, the test data can be used as a guide for the relevant durability performance in actual wearing.

When the difference between the experimental data is small, the experimental data is not suitable for indicating the durability of different materials. In general, laboratory data is not suitable for predicting durability in a specific application, unless there is data showing that the laboratory data has a specific relationship with actual wear.

5.5 The abrasion resistance test is applicable to various textile fabrics, including woven fabrics, non-woven fabrics, knitted garment fabrics, home textiles, industrial fabrics and carpets, etc. So there are a variety of different test instruments, abrasives, test conditions, test procedures and methods of evaluating and interpreting results.

5.6 At present, for all abrasion test standards and instruments, the results measured by different operators or between different laboratories show large deviations. But these test methods and instruments are the most widely adopted test methods.

5.7 Since there is a definite measure of frictional resistance, standard test methods are satisfactory and useful, and can be used to clarify problems and reduce confusion.

7.1 Lot Sample—As a batch sample for acceptance testing, a certain number of reels shall be randomly selected as the initial sample unit according to the agreement between the buyer and the seller or the material specification.

NOTE 2—A comprehensive specification or purchase agreement should include deviations between rolls or bulks, and between samples taken from the same batch or samples of a cloth.

variation, and variation between garments within the same case, in order to provide a sampling plan that takes into account producer risk, consumer risk, acceptable ranges, and defined quality levels.

7.2 Laboratory Samples—For Garment Acceptance Testing, take one garment from each box (see Note 2).

7.3 Test Specimens—Shear three (1.5 in.) 38 mm diameter test specimens from the sample with a sampler.

- Instrument Preparation

8.1 Assemble, maintain and adjust the instrument according to the instrument manual.

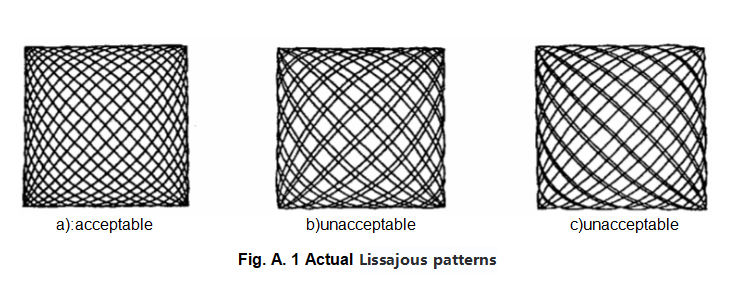

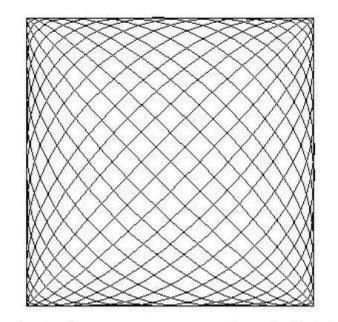

8.2 Test precautions see A.1.1.

- Humidity adjustment

9.1 Perform preconditioning and conditioning in accordance with the conditions specified in D1776. Equilibrium is considered to be reached when the sample weight does not change by more than 0.1% every two hours.

9.2 Before the test, put the sample in the atmospheric condition with a temperature of 70+2 (21+1°C) and a relative humidity of 65+2% for at least 4 hours.

- Test procedure

10.1 All Martindale fabric abrasion testing procedures shall be carried out under a standard atmosphere.

10.2 Place a piece of wool felt approximately 5.5 in. (140 mm) in diameter on each test bench and place a standard abrasive of the same size on top of the wool felt. Place the weight (included with the instrument) on the friction table to flatten the wool felt and abrasives. Put the wool felt and abrasives together while pressing the weight

Fix it on the friction table, then remove the weight to check for wrinkles.

10.3 When evaluating a test sample using Method 3 (see 11.3), first weigh the test sample to the nearest 1 mg.

10.4 Clamp the sample with a sample clamp and make it face down. If the sample is lighter than 14.7ozyd° (500g/㎡), place the sample between the sample and the sample clamp

Pad 1 1/4in. (38mm) polyurethane foam. Install the specimen holder according to the manufacturer’s instructions.

10.5 Place the sample holder on the grinding table, and apply the required pressure. For the fabric, a pressure of 1.31+0.03 psi (9±0.2kPa) must be added.

Upholstery fabric plus 1.74+0.04psi (12+0.3kPa) pressure.

10.6 Adjust the counter to zero according to the instrument manual, preset the appropriate number of times, and start the machine. For evaluation methods 1 and 2 (see 11.1

and 11.2) Observe the condition of the specimen until the end of the test is reached. When approaching the end of the experiment, reduce the interval of observations. Use scissors to trim any hairballs that appear.

If evaluation method 3 (see 11.3) is used to interpret the results, weigh the sample to the nearest 1 mg at the specified number of rubbings.

- Evaluation

11.1 Method 1—Woven fabrics are worn to break two or more yarns, and knitted fabrics are worn to a hole as the test termination condition.

11.2 Method 2—When the color of the sample is worn away or its appearance changes will cause consumers to complain, it is used as the test termination condition.

11.2.1 The fading of the sample may be caused by many reasons, such as the finishing agent on the surface is worn off, the loops or decorative lines are worn off, etc. when dyed with different

When different fibers dyed by different color methods are blended, different fiber losses will cause obvious changes in appearance and color. In this case use AATCCF25.

Fabric testing with Martindale Machines has the following necessities:

Materials requiring Martindale rub testing include, but are not limited to:

Textiles: such as fabrics, jeans, shirts, etc.;

Leather products: such as leather shoes, leather bags, etc.;

Plastic products: such as plastic shoes, plastic handbags, etc.;

Wood products: such as wooden suitcases, wooden furniture, etc.;

Metal products: such as aluminum tableware, stainless steel pots, etc.

These materials are subject to abrasion testing to ensure their durability and quality. The Martindale Test is an affordable, simple and efficient fabric durability assessment tool that objectively evaluates how materials will perform under varying conditions, helping manufacturers and consumers make informed decisions.

Ensure product quality and durability: Through the Martindale Abrasion Test, the abrasion resistance and pilling resistance of fabrics can be evaluated, so as to effectively guarantee the quality and durability of products and meet consumer needs and market changes.

Reduce production costs and waste of resources: Passing the Martindale wear test can avoid production costs and waste of resources caused by undurable fabrics, such as replacement, repair, scrapping, etc., thereby improving the competitiveness and brand image of the enterprise.

Meet the requirements of relevant standards: such as the international standard ISO 12944, the domestic standard FZ/T 01053, etc., have stipulated the abrasion resistance and pilling resistance of the fabric, and the Martindale abrasion resistance test can meet the requirements of these standards.

Objectively evaluate product performance: The Martindale Abrasion Test is an affordable, simple and efficient fabric durability evaluation tool that can objectively evaluate the performance of fabrics under different conditions, helping manufacturers and consumers to make informed decisions .

In a word, testing fabrics with Martindale wear-resistant instruments can help manufacturers improve product quality and durability, reduce production costs and waste of resources, meet relevant standards, and objectively evaluate fabric performance. Therefore, it is necessary to test fabrics using Martindale wear-resistant instruments.

Martindale abrasion tester for sale NOW! Please don’t hesitate to contact us.

Email: sales@chiuvention.com

WhatsApp: +86 180 2511 4082