Colour fastness to washing is also called washing/soap fastness. It is a textile’s ability to keep its original colour when washed. It is the ability not to fade or change. Washing is common for clothing care. Color fastness to washing simulates textiles’ color fastness in different detergents and washes. There are various ways to do colour fastness to washing. The principle is to imitate washing at the right time and heat. After stirring and rinsing, do this. Then, compare the grey sample to the original to check for color changes. The temperature may vary. So may the test solution, washing method, and use of steel balls. Also, the drying method may differ.

Test Principle

The washing test checks color fastness. It fits a textile with one or two lining fabrics. Then, it soaks them in soap, rinses them, and dries them after shaking. Researchers conduct the test at specific times and temperatures. Usually, someone places the specimen in a steel cup and strikes it with steel balls. We use a grey sample card to assess the discolouration of the test specimen. And, we use it to assess the staining of the lining fabric. There are five test methods for color fastness to washing. The main difference is the test temperatures and times. But, the methods are otherwise the same.

Test standard

ISO 105-C01-C05-1989 “Colour fastness of textiles – Colour fastness to washing: Test 1 – Test 5”.

EN 20105C01-C05-1992 “Textiles – Colour fastness test – Colour fastness to washing: Test 1 – Test 5”.

DINEN 20105C01-C05-1993 “Textiles – Colour fastness tests – Colour fastness to washing: Test 1 – Test 5”.

AATCC 172-2002 “Colour fastness to oxygen-free bleaching in home washing”.

GB/T 3921.1-5-1997 《Textiles-Colour fastness test-Colour fastness to washing:Test 1-Test 5

ISO 105-C01-C05 specifies many test methods for color fastness to washing. They cover a range of washing types from mild to severe. These methods are still widely used as classic color fastness tests. Manufacturers use ISO 105-C03 to test how well cotton fabrics keep their color. They do this by washing them. ISO 105-C03 forms the basis of the Chinese GB/T3921.3-1997 standard. It is the same as the ISO standard and applies to any textile. In addition to the above standards, there are also many international standards. They cover color fastness to washing of textiles. Examples include BS 1006-C01 of the UK and JISL 0844 of Japan.

Comparison of test methods

Chinese standard (GB/T 3921.3-1997)

Take a 4cm * 10cm specimen of the front and a piece of 4 ~ 10cm of multi-fibre lining fabric. Put them together along a short side of the sewing. Then, put them into a (550 ± 50) mL [diameter (75 ± 5) mL, high (125 ± 10) mL] stainless steel container. Inject the container with soap preheated to (60 ± 2) ℃. The bath ratio is 50:1. Combine specimens at (60 ± 2) ℃ for 30 minutes. They then removed and washed them 2 times with cold water. Finally, they rinsed the items in cold water for 10 minutes. Squeeze out the water from the specimens. A seam connects only the specimen and the lining. Hang them to dry at not more than 60 ℃. Take out the dried specimens. They are a combination of colors. Use a grey card to assess their discoloration and the staining on the fabric.

American Association of Textile Chemists and Colourists Standard (AATCC 61A-2003)

Take a 50mm by 100mm specimen. Put its front and a 5mm by 100mm lining fabric together with a short edge sewing. This forms a combination of specimens. Put them into (550 ± 50) mL stainless steel containers. The containers must have a diameter of (75 ± 5) mL and a height of (125 ± 10) mL. Inject 200mL of soap solution into the containers. Keep the solution at a temperature of (40 ± 2) ℃, and preheat the containers to this temperature. He heated the combined specimen to (40±2)°C for 45 min. The procedure involved removing and rinsing it three times with distilled water at (40±3)°C for 1 minute. Then, someone squeezed out the water. Unfold the combined specimen. A seam connects the specimen and the lining. They hang in the air at 71 ℃ dry. Take out the dried combined specimen. Evaluate its discolouration and the staining of the lining fabric with a grey card.

Japanese Industrial Standard (JISL 0844-2005)

We took a 4cm*10cm specimen. A 4cm*5cm cotton backing and a 4cm*5cm nylon backing contacted the front side of the specimen. They stitched along one short side to form a combined specimen. Someone placed it in a stainless steel container with a capacity of (550±50) mL [diameter (75±5) mL, height (125±10) mL]. After preheating the tub to (50±2) °C, we filled it with the right amount of soapy water at a bath ratio of 50:1. The required amount of soap, bath ratio of 50:1. Treating the combined specimens at (50 ± 2) ℃ for 30 min. They then removed and washed them twice with cold tertiary water. Next, they rinsed the items in running cold water for 10 minutes and squeezed them dry. Make the specimens bigger. The specimen and lining should only connect by a seam. They should hang in the air at no more than 60 ℃ dry. Take out the dried combined specimen. Use the grey sample card to assess its discolouration and the staining of the lining fabric.

The testing process

This is an example for you to introduce. It is from the testing process in GB/T 3921-2008.

1 Specimen

The test is for “colour fastness to soap washing.” Take a 100mm by 40mm piece of front and a piece of 100mm by 40mm multi-fibre lining fabric. Put them into contact along a short side by stitching. This forms a combination of specimens. Or take a 100mm by 40mm specimen. Two 100mm by 40mm single-fibre lining fabric sandwich it. They are sewn together along a short side, forming a combination of specimens. If the specimen consists of a blend or interwoven products, the main fiber incorporates the secondary fiber.

2 Preparation of test solution

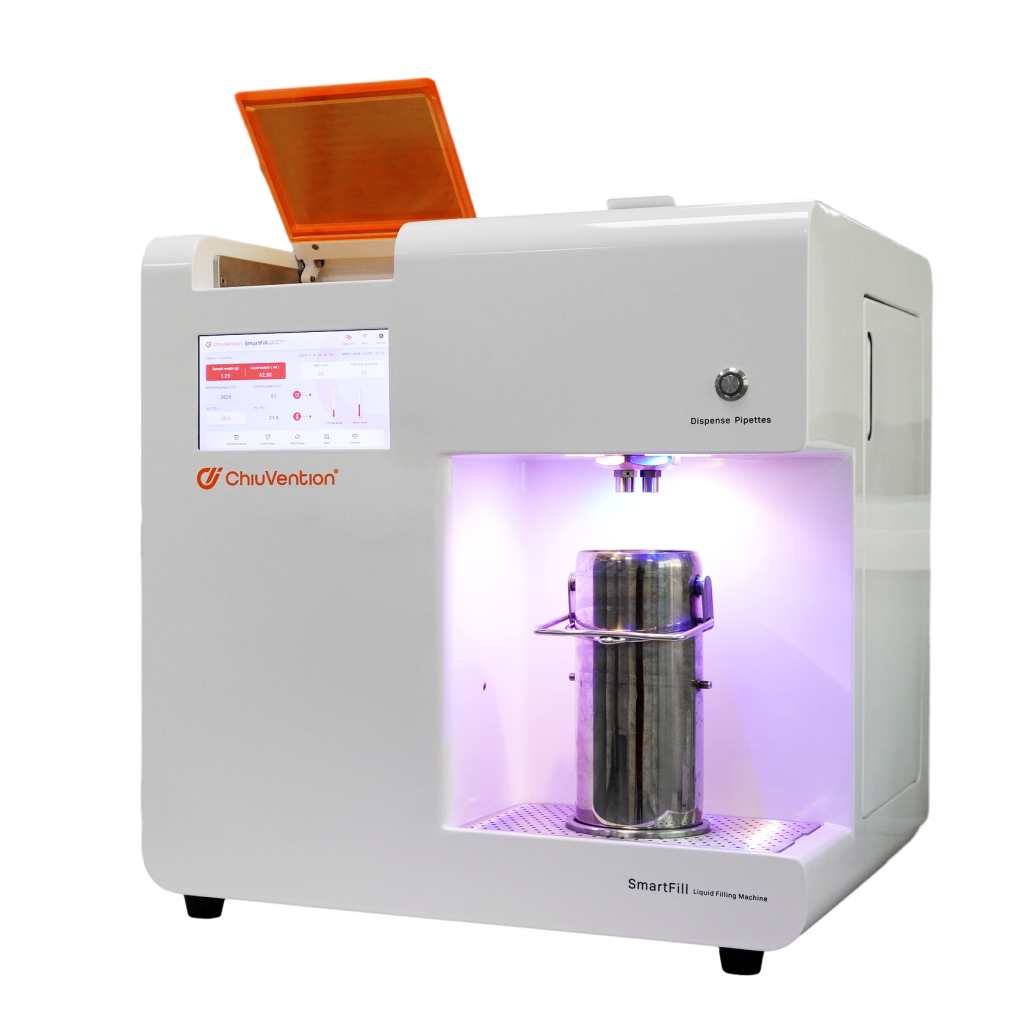

We prepared the test solutions as follows. Each liter of tertiary water for tests A and B had 5 grams of standard soap. For tests C, D, and E, we used tertiary water with 5 grams of standard soap and 2 grams of anhydrous sodium carbonate. The SmartFill is an add-on for washing color fastness testing. It can greatly boost the test’s accuracy and speed. It has its own scale. After weighing the samples, it readies and heats the detergent. It follows the set bath ratio. Then, it adds hot detergent and steel balls to the test cup. The Liquid Filler makes sample prep more accurate and efficient. You can conduct the wash color fastness test immediately. So, no waiting. This enhances economic efficiency.

3Conduct the test

Put the combined specimen and the specified number of steel balls in a container. Fill it with the right amount of soap. Heat the soap to the test temperature ± 2°C. Do this under the standard test conditions. These conditions make the bath ratio 50:1. Close the container. Then, turn on the machine to the standard temperature and time. Time the container when you close it. The WashTrue color fastness tester uses smart temperature control. It ensures that wash fastness tests follow requirements and give reliable results. You can do a series of test operations on the touch screen. These include selecting standards, parameters, time, and temperature setting. You can also control water filling and draining. This system is smart and efficient. The buzzer will automatically alert you when the test is complete. Multi-safety design, and can be low noise and long time running.

4 Rinsing and drying

For all tests, take out the combined specimen after washing. Put it in three levels of water to wash twice. Then, rinse it in flowing cold water until clean. Squeeze out the water. Then, take apart the specimen. Leave it attached only at the seam line. Lay it flat between two unused filter paper sheets to remove water. Then, hang it in the air to dry at a temperature of 60°C or less.

Test results

Test results show that we use an instrument or a grey card to assess the discolouration. It also assesses the staining of the lining fabric. The test will measure the degree of staining. It will use a specified light source and a standard grey card. We will rate the result on a 5-point scale. A rating of 5 is the best and 1 is the worst.

Instrument ratings

An instrument uses the standard reflectance of a known specification whiteboard to calibrate. It finds the spectral power distribution of the sample’s reflection. Or, it finds the brightness of its own reflection. Then, it uses the spectral data to calculate the object’s three impact values. It finds its chromaticity coordinates, CIELAB color space, and more. After a series of formulas, it gets the grey card rating.

Grey sample card rating

This rates fastness to fading and staining by color. The Grey card has two parts. One for color change and one for staining. Both have five levels of nine grades. The light should be sunny (9:00 ~ 15:00) or bright (6001x+). It should be at a 40° angle to the textile. You should look at the textile surface straight on. Use the grey samples card to assess the specimen’s discoloration and cloth staining.

Test Error Analysis

Different lining fabrics will cause test errors. Even when using the same sample and method, this still occurs. Using different fabrics for staining tests results in varying outcomes. The fabric’s staining performance depends on its multi-fibre lining. It is due to the fabric’s structure, composition, yarn, density, and finishing process. These factors directly lead to differences in the fabric’s staining. This variation impacts the test results.

The standard light source box rates the color fastness of the specimen. But, the rating time is too long. The bright light causes eye fatigue. This affects the rating’s accuracy.

Rate the lighting, rating angle is 40°. The observer’s line of sight should be 90° to the surface. They should be 30 ~ 40cm away. Otherwise, it will affect the rating.

Whether you remove the loose fibers on the lining or not also affects the rating.

Conclusion

The values for color fastness to washing differ a lot. Different national standards measure them. The Chinese standard for color fastness to washing has stricter tests. They are stricter than the American and Japanese ones.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: medium@chiuvention.com