Have you used a Martindale tester? If you have, have you ever used a Martindale abrasion and pilling tester that can be connected to the phone? Next, I will introduce to you how the Martindale abrasion and pilling tester is connected to the mobile phone and how it becomes intelligent.

What is a Martindale machine used for?

The Martindale abrasion tester, one kind of fabric abrasion testers, is designed to determine the abrasion and pilling resistance properties of various textile structures.

It can test the abrasion resistance and pilling performance of cotton, hemp, silk woven fabrics and other textiles, membrane materials, knitted fabrics, woolen textiles, artifificial leather, synthetic eather, gloves, labor protection materials, etc.

Test Principle of a Martindale Pilling Tester Machine

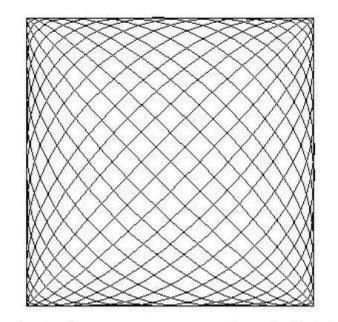

A circular specimen is placed on the grinding head and, under the prescribed pressure, is placed in planar contact with a standard woolen abrasive fifixed on the grinding table and rubbed in a multi-directional translation according to the LISSAJOUS trajectory (a composite trajectory of two mutually perpendicular resonant motions) until the specimen is ground to a prescribed number of times and the Martindale Test Equipment stops automatically. Then the number of abrasion or pilling is compared with the standard parameters and the result is obtained.

What is the ChiuVention Smartindale Martindale Abrasion and Pilling Tester?

It is a new generation of intelligent Martindale Abrasion Tester developed by ChiuVention.It completely destabilizes the traditional textile testing mode.

Advantages of Smartindale Martindale Abrasion &Pilling Tester

The original digital drive, achieves a higher level of test accuracy

Smartindale replaced the traditional analog drive with a digital drive, an exclusive innovation in the industry, the combination of dual servo motors, microcontroller, embedded, mathematical model, point-to-point drive, etc.,

single point directly generated LISSAJOUS, with higher precision and reliability of the Martindale test equipment.

Unique calibration-free function

The dual action of servo drive and position sensor allows the instrument to continuously achieve accurate testing.

Smart instruments, IOT function

We have developed a unique SmarTexLab system that links instruments and mobile phones, equipped with IOT functions, The SmarTexLab system have these functions:can be networked with cell phones, set parameters on the cell phone, monitor the test status, get equipment warning reminders, supplies replenishment reminders, etc., and share equipment test status with one click.

The IOT functions allows friendly communication between textile brand owners and downstream supply chain enterprises. In the SmarTexLab system, from brand buyers to suppliers, all parties can monitor the testing process and obtain results in real-time through their mobile phones, and every testing record can be traced. This makes textile testing more transparent, reliable, and efficient.

Test modes can be switched by one-touch

No need to change pins, direct on-screen switching to achieve multiple test modes (e.g. straight line mode, large trajectory mode, small trajectory mode).

Humanized design, safer guarantee

Lifting arm beam, moving guide plate can be operated by one hand and automatically closed, anti-collision, more friendly to testers.

Precision manufacturing, stable operation

The fifixture rotates flflexibly, the grinding table and specimen fifixture are highly parallel, and the machine has a small runout with the surface of the grinding table (less than 0.05mm), which is more conducive to obtaining

reliable test results.

Other features of Smartindale Martindale Abrasion &Pilling Tester

Precise appearance design, aluminum alloy hard oxidation surface, durable and easy to clean, trapezoidal chassis is more stable, seven-inch color touch screen is easy to use.

Three kinds of speed measurement to meet different needs: slow (24rpm), normal (47.5rpm), fast (75rpm).

Get the Martindale abrasion tester price now by contacting us through the picture below.

Specifications of the Smartindale Martindale Abrasion and Pilling Tester

Abrasion resistance test

Max stroke of movement 60.5+/-0.5mm

Weight of holder and spindle 198+/-2g

Pilling resistance test

Max stroke of movement 24+/-0.5mm

Weight of holder and spindle 155+/-1g

Accessories of the Smartindale Martindale Abrasion &Pilling Tester

Fuse tube: 2pcs

Foam wool :9 pcs ∅38 mm

Wool felt: 18 pcs ∅90 mm,∅140 mm

Wool abrasive :9 pcs ∅140 mm

Sampling plate: 3 pcs ∅38 mm, ∅90 mm, ∅140 mm

Sampler: 1 pc for pilling test

Sampler: 1 pc for abrasion resistance test

Press: 1 pc ∅126mm, 2.5kg

Fixture1: 9 sets for pilling test

Fixture 2: 9 sets for abrasion test

Weight 1: 9 sets 12Kpa

Weight 2: 9 sets 9Kpa

Rubber ring: 9pcs for pilling test

Test pen: 1pc

Connection shaft: 9pcs for pilling test

Stainless steel ring: 9pcs 260g

Connection shaft :9pcs for abrasion test

Optional Accessories of the Smartindale Martindale Abrasion &Pilling Tester

EMPA990 rating chart card :1 set knitted + Woven

SM50 rating chart card :1 set IWS + ASTM

SM25 abrasion resistant :

wool cloth: 1 pack 1.6 X 5m/pack

SM26 woven wool felt: 1 box 24 pcs/box ∅140mm

SM26 woven wool felt :1 box 24 pcs/box ∅90 mm

SM28 polyurethane ether :

Foam: 1box 250 X 200mm/pc, 25pcs/box

Standards of the Smartindale Martindale Abrasion &Pilling Tester

ISO 12945-2-2020 ISO12947-1-1998 ISO12947-2-1998

ISO12947-3-1998 ISO12947-4-1998 GB/T 21196.1-2007

GB/T 21196.2-2007 GB/T 21196.3-2007 GB/T 21196.4-2007

GB/T 4802.2-2008 BS EN 530-2010 ASTM D4970/4970M-2016e3 ASTM D 4966-12 ISO20344-2011

Optional Standards of the Smartindale Martindale Abrasion &Pilling Tester

BS EN 388-2016+A1-2018 SATRATM31 A/B PUMA

BS EN 16094-2012

Precautions on Martindale Pilling Tester

The friction cloth can not be used repeatedly, each completed test need to replace a friction cloth.

Wool felt can be used repeatedly until the surface is worn or has been stained when it needs to be replaced.

The insole should be removed from the cloth first, and then Martindale wear test.

After the test is completed, if the surface of the sample is worn out, broken yarn, pilling or serious pilling, serious wear and other abnormal phenomena, it will be judged as unqualified.

Testing Procedures of the Martindale Pilling Tester Machine

The specimen is parked in the laboratory environment for more than 8 hours.

Cut a piece of specimen on the flat part of the specimen, in the case of insole, it should be cut to the transfer part.

Remove the load and load axle bar from the testing machine.

Remove the top plate and test fixture.

The device of the specimen: loosen the fixing ring on the test fixture, take off the specimen press, put the specimen into the base of the test fixture, pad a specimen spacer between the specimen and the base of the test fixture, then place the specimen press on the specimen spacer and fix it with the fixing ring.

Wool felt and friction cloth device: loosen the set screw good fixed ring, the wool felt placed on the base and then laid on the friction cloth, in the middle of the friction cloth on the pressure plate of 2.5KG, installed back to the fixed ring and lock the set screw.

Put back the top plate, the load axis rod (12KPA), break through the round hole in the top plate.

Place the test fixture with the specimen face down on the base fixture, adjust the round recess of the test fixture to align with the load shaft, so that the load shaft is inserted into the round recess of the test fixture.

According to the standard set number of times, start the switch, start the test, and automatically stop after reaching the set number of times.

Maintenance Tips for the Martindale Pilling Machine Instrument

Turn off the power when the instrument is not working.

If it is not used for a long time, please remove the test press plate, spray anti-rust oil and lubricate the gear parts every month.

The exterior of the instrument must be cleaned regularly and the cylindrical shaft under test must be wiped before and after the experiment to keep the instrument clean.

Periodically check the test instrument for any abnormal operation. Generally, the friction head will draw the trajectory of Liza as a curve. The deformation of the guide plate, friction head guide shaft, and friction head will affect the trajectory of friction movement and have an adverse effect on the test. Therefore, we need to protect the integrity of the accessories.

In order to protect the service life of the instrument, the user is required to operate the instrument in the correct manner and not to operate the instrument without authorization. If you are unable to find out the cause of the malfunction of the instrument by yourself, you should contact the manufacturer immediately and repair it under the guidance of professional engineers.

Evaluation Methods of the Martindale Abrasion MachineTest Results

There are three Martindale methods for evaluating the abrasion resistance of fabrics: the specimen breakage method, the mass loss method and the appearance quality change method. The most commonly used of the three methods is the specimen fracture method, which has low error, intuitive test results and easy comparison of abrasion resistance of different fabrics. The mass loss method and the appearance quality change method are more complicated to evaluate, but they can reflect the abrasion resistance of the sample at different friction stages. It is highly practical for use in analyzing fabrics in manufacturing companies or research institutions.

How to analyze Martindale test results?

Take the sample breakage method as an example. Martindale machine test results are usually given as a score of 1000 rubs or cycles completed. The higher the score for rubs or cycles, the more suitable the fabric is for heavier applications. We basically classify fabrics based on the test results.

Studies have shown that when results of less than 1000 rubs are obtained, the fabric is recommended for decorative purposes (i.e. accents and mats) and, therefore, is not recommended for general use.

If the fabric produces results of 10,000 to 15,000 wipes, the fabric is strongly recommended for occasional use on furniture. The fabric is recommended for light domestic use because the fabric is delicately constructed or because the fabric is made of fine yarn.

If the fabric provides 25,000 to 30,000 rubs, it can be used for heavy-duty work (on the main furniture of the house, which will be used continuously every day).

If the number of wipes exceeds 30,000, the fabric is suitable for both commercial and heavy-duty use (commercial furniture and the environment).

Finally, when people notice that they have more than 50,000, they run into problems. The answer is that such rubbing has little impact in practical applications, this is because the Martindale test is only used for abrasion resistance, some other factor affects the wear of the fabric, other factors such as chemicals used to wash the fabric, UV exposure, etc., just as a fabric with a high rubbing number means that the fabric is resistant to cat claws.

9.Points to consider prior to abrasion testing/factors affecting abrasion testing

Specimen condition: The fabric should be conditioned and tested in a standard test atmosphere.

Choice of test apparatus: The choice of test apparatus may depend on the characteristics to be tested, e.g. .g-flat wear, bending wear, etc.

Choice of abrasive motion: The frictional motion may be reciprocating, rotating or multidirectional.

Direction of wear: The direction of wear can be at an angle to the warp and weft direction.

Choice of abrasive: The severity of wear can vary with the nature of the abrasive. For example, steel and silicon carbide have constant abrasiveness.

Standard worsted or canvas fabrics, various grades of emery cloth are also used as abrasives.

Support specimens: The hardness of the specimen backing may affect the results. Hard backing is used in some specimens and felt or foam rubber in others.

Cleanliness of specimens and instruments: Areas to be abraded should be handled as little as possible and be free of foreign matter, such as graphite from pencils. Instrument accessories that may rub against the fabric must be spotless and free of grease.

Tension on the specimen: The specimen should be mounted using the S tandem method to avoid errors due to variations in the tension used.

Pressure between abrasive and specimen: The severity of the abrasion will be influenced by the pressure applied. Therefore, it is important to establish suitable criteria.

End point of the test: The test should always be stopped once the hole has been appeased or the specimen has broken through the automatic stop motion.

Factors affecting abrasion resistance

Fiber type

Nylon is generally considered to have suitable abrasion resistance. Polyester and polypropylene also have good abrasion resistance. Blending nylon or polyester with wool and cotton has been found to increase its abrasion resistance. Viscose and acetates have the lowest abrasion resistance.

Fiber properties

Fabrics made from longer fibers have better abrasion resistance than shorter fibers because they are more difficult to remove from the yarn. For the same reason, filament yarns are more abrasion resistant than staple yarns made from the same fibers. Increasing the fiber diameter to the limit increases abrasion resistance.

Yarn twist

The right amount of twist in the yarn provides the right abrasion resistance. At low twist factors, the fibers can be easily removed from the yarn, allowing for a gradual reduction in diameter. At high twist, the fibers are held tighter, but the yarn is stiffer and therefore wears hard under pressure

Fabric structure

Fabrics with curls evenly distributed between the warp and weft yarns have suitable abrasion resistance because damage is evenly distributed between them.