Clothes fabric wrinkles, directly affecting its beauty and wearing effect. So, why do clothes wrinkle, and how do anti-wrinkle treatments in daily life?

This article will explain the reasons for fabric wrinkling, and the full procedures of the fabric crease recovery test including the test principle, test instrument, test steps, and the interpretation of test results.

Reasons for Fabric Wrinkling

Fabrics in the process of wearing and washing care, due to rubbing, squeezing, twisting, twisting and other external forces produce folds or wrinkles in the phenomenon known as wrinkles.

Microscopic Point of View

Under the action of external forces, the fibres constituting the fabric undergo deformation, and after the removal of the external forces, the deformation cannot disappear, and cannot be restored to its original state or can only be partially restored.

When the fibres are subjected to external forces:

(1) In the high degree of regularity of the crystalline region, the molecular chain arrangement is more neat, the formation of hydrogen bonding, and can withstand the action of external forces together. Therefore, in the elastic limit is not exceeded under the action of external forces, generally only a small reversible deformation, that is, general elastic deformation.

(2) In the lower degree of regularity of the amorphous zone, in the free state of the hydroxyl group formed by the hydrogen bond is less, in the process of washing or wearing the external force, cellulose molecules along the direction of the external force to occur a certain amount of deformation, the basic structure of the unit of the relative slip, and the hydroxyl group in the new position will produce a new hydrogen bonding to make the deformation is fixed down when the removal of the external force, the system undergoes creep to return, if the resistance of the new hydrogen bonding is greater than the restoring force, if the new hydrogen bonding to produce If the resistance of the newly formed hydrogen bond is greater than the restoring force, the deformation of the system cannot be restored, and then permanent deformation occurs. Due to the diversity of hydrogen bonding arrangement and the production of a variety of morphological changes, this uneven and irreversible deformation of the macro-expression is the fabric wrinkles.

Macroscopic Point of View

The formation of a crease can be divided into two stages: crease generation and crease recovery after the removal of external force.

Crease generation

Under the action of external force, the fabric produces bending deformation, because the action of the external force is much larger than the resistance of the fabric due to bending, therefore, the fabric is forced to bend deformation, i.e., beyond the elastic deformation range of the fabric bending, resulting in yield deformation.

This deformation includes the warp and weft yarns of the fabric between the slip misalignment, the slip between the yarn fibres, and fibre stretch deformation under the action of external forces. The fabric in a certain deformation, with the continuation of the time of external force, the fabric stress continues to weaken, that is, to produce stress relaxation. Therefore, whether the fabric produces crease depends on the fabric deformation and the relaxation state of the fabric’s internal stress.

Crease recovery

After the removal of external force, the fabric under the action of the elastic recovery force generated by the internal stress, the fabric’s crease bending begins to produce a response, that is, the angle of the crease recovery begins to increase. With the continuation of time, the crease recovery angle increases continuously, and its change is similar to the material creep law.

In this process, in addition to the elastic restoring force of the fabric, it is also affected by the frictional resistance, which is generated by the relative slip between the yarns and between the fibres of the yarns, and its direction is opposite to the elastic restoring force. When the fabric’s elastic recovery force and frictional resistance are balanced, the fabric reaches the maximum recovery effect, and the fabric fold angle at this time is the fabric’s crease recovery angle.

Fabric Crease Recovery Test

The testing methods of fabric crease recovery are AATCC 66, FZ/T 70006, GB/T 3189, EN 22313, JISL1059-1, ISO 2313 and so on. The testing principles of these methods are very similar, now the GB/T 3189 test method is described below.

Testing Principle

The specimen of a certain shape and size is folded and pressurised under the specified conditions for a certain period of time. After unloading, let the specimen go through a certain recovery time, then measure the crease recovery angle, and use the measured angle to indicate the crease recovery ability of the fabric, and the larger the value, the better the crease recovery ability. This method is applicable to all kinds of textile fabrics, but it is not applicable to fabrics which are particularly soft or very easy to roll up. Two methods are commonly used: the horizontal method and the vertical method. In the horizontal method, the crease line of the specimen is parallel to the horizontal plane when the crease recovery angle is determined. In the vertical method, the crease line of the specimen is perpendicular to the horizontal plane when the angle of return of the crease is measured.

InnoFlex Bally Flexing Tester has been widely used in the world, with 12 workstations that can be selected, and can choose single station/multi-station mode.

Equipped with advanced servo motors for precise positioning, and a stable testing process, the InnoFlex Bally Flexing Tester can achieve more accurate and reliable test results. It is a smart instrument that can be connected to the SmarTexLab app installed in your smartphone via WIFI, which allows you to remotely set the parameters and monitor the testing process, greatly improving work efficiency.

Testing Instrument

(1) Basic conditions of the instrument

① Pressure load is 10N.

② the area subject to pressure load: 15mm × 15mm horizontal method; vertical method is 18mm × 15mm.

The pressure loaded area: is 15mm x 15mm for the horizontal method; and 18mm x 15mm for the vertical method.

③ The pressure loaded time is 5min and 5s.

④ The index value of the dial of the response angle measuring device is ±1°.

⑤ The specimen table shall be appropriately shielded to ensure that the specimen is not affected by environmental conditions such as ventilation, operator’s respiration and thermal radiation from lamps.

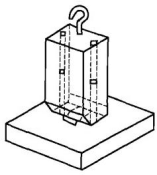

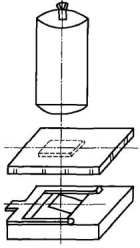

(2) Horizontal method pressure loading and test devices

Figure 3-29 and Figure 3-30 show the horizontal method of pressure loading and test devices

Figure 3-29 Horizontal method specimen pressurisation device with vertical guide rails

Figure 3-30 Horizontal Method Crease Recovery Angle Measuring Device

Figure 3-30 Horizontal Method Crease Recovery Angle Measuring Device

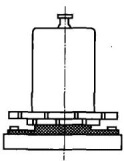

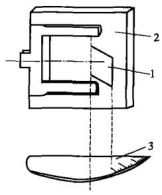

(3) Vertical method pressure loading and testing device

Figures 3-31 and 3-32 show the horizontal method pressure loading and test device

Figure 3-31 Schematic diagram of specimen pressurisation device for vertical method

Figure 3-32 Vertical method of measuring crease return angle measuring device

1-specimen; 2-specimen clamp; 3- protractor

Measurement Steps

(1) Horizontal method

① Fold both ends of the specimen in the lengthwise direction, and then clamp it with wide-necked pliers, with the clamping position not more than 5mm away from the end of the cloth, and then move it to the plate marked with 15mm×20mm, so that the specimen can be positioned correctly, and then gently add pressure to the weight.

② Specimen under the specified load, ensure that the specified time, remove the load, will be clamped with the specimen of the wide-necked pliers to transfer the specimen clamp to the angle of return measurement device, so that one wing of the specimen is clamped, and the other wing is free to hang, and continuously adjust the specimen clamp, so that the hanging down the free wing is always maintained in a vertical position.

③ Read the angle of return of the crease 5 min after the specimen is unloaded from the pressure loading device, and the reading is accurate to 1°. If the freewheel is slightly curled or twisted, the vertical plane through the centre of the freewheel and the axis of the dial shall be used as the reference for reading the angle of return of the crease.

(2) Vertical method

① The fixed-wing of the specimen into the specimen clamp, so that the folding line of the specimen and the specimen clamp folding mark line coincide, along the folding line of the specimen folding, do not apply any pressure in the folding, and then in the folded specimen put on the transparent pressure plate, and then add the pressure of the hammer.

② specimen to withstand the pressure load to reach the required time, quickly remove the pressure load, and the specimen clamp together with the transparent platen turned 90 °, and then remove the transparent platen, while the specimen to return to the wing open.

③ After the specimen is unloaded and reaches 5min, the angle of return of the crease is read by the angle measuring device, and the reading is accurate to 1°, if there is a slight curl or torsion during the return, the centre line of the straight part of the root is taken as the base.

(3) Notes

① If the specimen has a tendency to stick, between the two wings from the crease line 2mm placed a thickness of less than 0.02mm sheet of paper or plastic sheet.

② After the specimen is wetted, it can only be touched with tweezers or rubber finger cots during operation.

Expression of Test Results

Calculate the average of the following directions, calculated to one decimal place, according to the rules of numerical modification to retain the whole number of digits.

① Warp direction (longitudinal) crease recovery angle: front face-to-face fold; reverse face-to-face fold.

② Latitudinal (horizontal) crease angle of return: front face to face fold; reverse face fold.

③ Total crease recovery angle: the sum of the average value of the return angle of the crease in the longitudinal and latitudinal directions.

Conclusion

For any fabric, the angle of repose of the two test methods, the value obtained by the vertical method is greater than that of the horizontal method; the same type of fabric for the angle of repose test, the unit area of the quality of the lighter, that is, less than 200 g/m2, the results of the horizontal method of measurement is more stable and accurate; unit area of the quality of the heavier, that is, higher than 200 g/m2, vertical method of measurement of the results of a more stable, and efficient; according to the quality of the unit area of the fabric to choose a different Choosing different testing methods according to the unit area mass of fabrics can better characterise the good or bad crease resistance of fabrics.