Hey guys! Welcome to the complete guide to textile pretreatment processes.

Have you ever wondered how plain raw materials turn into those excellent fabrics we love? Well, it all starts right here, with the critical pretreatment steps.

Pretreatment is like giving the fabric a deep clean, removing all the dirt, and preparing it for the next big moment. It’s where simple cloth takes its first steps to become incredible and pretty.

You see, in fabric making, pretreatment is an absolute must. It’s the foundation that sets the stage for the fabric to shine bright, and once the fabric has gone through pretreatment, it is ready for its next journey of getting dyed and finished to perfection.

So, get ready to dive into the fascinating world of textile pretreatment. Let’s uncover the secrets behind how fabrics feel, look, and last.

Before the textile becomes the Kaleidoscope of colors we all love to wear; there is a crucial journey to process and prepare the fabric. It’s like crafting the perfect canvas for a masterpiece. This is a meticulous process, and the crucial first move fortifies the fabric’s strength and ensures its versatility to meet various needs. But here’s the real magic: the secret ingredient breathes into the final product an irresistible blend of texture and luminosity.

Now you might be wondering what the types of textiles are, well look no further;

Regarding pretreatment techniques, they work their magic on all sorts of fabrics, from natural wonders to synthetic ones.

We’re talking about a wide range here, my friend—cotton, wool, silk, and even those artificial wonders.

The key is finding the perfect method for each fabric, ensuring it brings out the best in quality and character. It’s like a tailor-made treatment for every textile. It’s pretty much like giving each textile a personalized VIP treatment.

Textile Pretreatment: Step By Step Guide

Now let’s take a look at the steps in pretreatment

Step 1、Singeing

This is the first step in getting those textiles ready for their grand debut in fashion. This crucial step sets the stage for how fantastic and smooth the fabric will turn out.

Let me break it down: singeing is like a meticulous fine-tuning process. It’s all about brushing off those extra fibers from the fabric, giving it that extra boost in smoothness and visual appeal. The fabric is engaged in a quick and careful dance with flames, creating a harmonious, perfect masterpiece.

Now, guys, when it comes to singeing machines, gas-singing machines are the go-to for most industries. But here’s the exciting part: each machine has unique perks tailored to different textiles. It’s like having a toolbox with a variety of options to choose from. The key is picking the suitable machine that suits your fabric and the specific look you aim for. To get the most out of the fabric, it’s all about getting the right match.

Evaluating singeing effectiveness

When evaluating the effectiveness of singeing, it all boils down to how smooth the fabric feels after treatment. The usual way to check is by giving it a quick look-over in bright light. It’s like inspecting the fabric under a spotlight, ensuring it’s as smooth as possible. And here’s the fun part: the smoothness gets a score ranging from 1 (least effective) to 5 (most effective). It’s like a rating system that tells us how well the singeing process worked.

Step 2、Desizing

Desizing is like the superhero of textile pretreatment. It’s the crucial phase that kicks off the transformation of raw fabric into top-notch textiles. Let’s dive into the desizing process together, shall we? This step is about removing those sneaky sizing substances from the warp yarns. It’s like giving the yarns a refreshing cleanse, especially after the singing process. Desizing works its magic by getting rid of any starch-based sizing agents that were added during weaving. It’s like waving goodbye to those unwanted elements and paving the way for a clean and fabulous fabric journey.

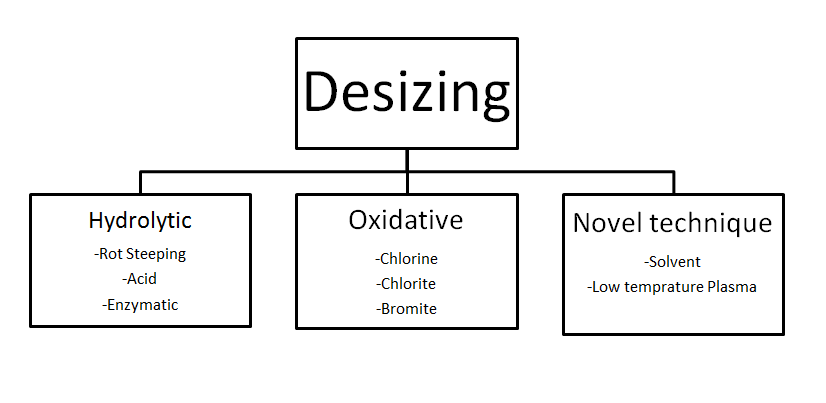

Types of Desizing Methods

Moving on, when it comes to designing, we can explore two main categories of methods. The method choice depends on the fabric type and sizing material used. Let’s dive into these methods together.

First, we have enzymatic desizing, a popular choice among textile industries. It’s known for its high efficiency and uses enzymes to work its magic. These enzymes transform starch into soluble sugars, which is neat if you ask me! Not only is this approach environmentally friendly, but it’s also gentle on the fabric itself. It’s like giving the fabric a sweet treat while keeping it happy and healthy.

On the other hand, we have alkali desizing, which is an excellent option for more sturdy fabrics. This method employs alkaline solutions to remove sizing materials. It’s highly effective in getting the job done but can be a bit tougher on the textile. Think of it as a solid and determined approach, perfect for tackling those more rigid fabrics requiring extra care. So, it all depends on the fabric and sizing material you’re working with

The Role of Desizing in Quality Fabric Production

It’s critical to remember that thorough desizing is essential in producing high-quality fabrics. It’s like the secret ingredient that ensures uniform dyeing and impeccable finishing. When desizing is skipped or not done correctly, it can lead to uneven dyeing and compromise the overall quality of the fabric.

What’s next?

Step 3、Scouring, Cleaning the Textiles, and Understanding the Process

Alright, let’s talk about scouring. When it comes to textile pretreatment, scouring takes center stage. It’s like the superhero of cleanliness. It gives a deep clean to fabrics and lays the groundwork for their magnificent transformation in their later stages. You might ask yourself, what is Its primary mission? Well, the answer’s simple. To strip away all impurities and leave behind pure, high-quality textiles. So, scouring is vital if you aim for top-notch fabrics that make heads turn.

Role of Scouring in Textile Manufacturing

Let’s dive into the role of scouring in textile manufacturing next! This process is like the ultimate prep session for fabrics before they move on to the exciting dyeing and finishing steps. It’s all about boosting the ability of fabrics to absorb dye and ensuring a smooth and even surface. And guess what? In scouring, we have some key players. Alkaline agents like caustic soda take the spotlight, while surfactants and wetting agents join forces to give fabrics a thorough cleanse, targeting all kinds of dirt. It’s like a dream team working together to make those textiles shine.

There are different aspects of scouring, and when it comes to removing impurities, scouring is a champ. It tackles everything from natural oils and waxes to stubborn soil and dust. It even takes care of proteins and bits of plants that get stuck in the fibers. And let me tell you, the impact of scouring on fabric quality is remarkable. It’s a game-changer for fabric, making fabrics look better and enhancing their texture. Different fabrics require different scouring techniques. Cotton can handle a strong scour, while wool and silk need a softer touch. And for synthetics, scouring is all about stripping off surface coatings. So, when assessing the effectiveness of scouring, keep an eye out for a fabric that soaks things up like a pro. Look for even color and texture without weakening the fibers—that’s the sign of scouring done right!

Step 4、Bleaching

Let’s talk about the power of bleaching in achieving that pristine fabric whiteness, my friend! Bleaching is vital in stripping away natural colors and fabric stains in textiles. Its primary purpose is to create an even and long-lasting brightness that enhances the fabric’s charm. And here’s the beauty of it: bleaching is carefully crafted to be potent yet gentle on the fibers, ensuring the fabric remains in top-notch condition.

Bleaching Agent and Their Applications

Let’s talk about the different bleaching agents and their applications. In textile bleaching, oxidative agents like sodium hypochlorite and hydrogen peroxide are commonly used. The choice of the agent depends on the fabric type and the desired bleaching effect. These powerful agents work by dismantling the color molecules, leaving the fabric colorless and ready for the next step. It’s all about finding the perfect match for that pristine look.

The Process of Bleaching

Let’s take a look at the process of bleaching. Bleaching unfolds in stages – first, we apply the bleaching agent, then allow it to react, and finally, wash it off. But here’s the key: controlling factors like temperature and pH are crucial for a successful outcome. When done right, bleaching removes color while maintaining the fabric’s quality. It’s all about finding that perfect balance.

Now, let’s talk about evaluating the outcomes of bleaching. Effective bleaching is measured by the whiteness achieved and the consistency of color removal. After bleaching, it’s essential to check the fabric’s strength and structure to ensure it remains undamaged. It’s all about achieving that perfect result while keeping the fabric in top-notch condition!

Step 5、Mercerizing

Mercerizing is a game-changer in enhancing fabric quality, especially for those luxurious textiles. This process ensures fabrics take up dye better and become stronger, my friend!

So, let’s dive into the purpose and process of mercerizing. It involves treating cotton with sodium hydroxide, permanently boosting its dye receptiveness. The result? A fabric that shines with a striking glow and delivers outstanding dyeing results. It’s all about elevating the fabric to new levels of beauty.

When fabrics undergo mercerizing, they show enhanced dye absorption, resulting in brighter and more enduring colors. Plus, it increases resistance to shrinkage and improves overall stability. It’s like giving fabrics superpowers.

Mercerizing plays a critical role in the world of high-quality cotton textile production. It requires careful management of chemicals and temperature, with tension kept just right throughout. It’s all about finding that perfect balance to achieve exceptional results.

But here’s the exciting part: mercerizing keeps evolving to meet the demands of the textile industry. Recent advancements focus on being eco-friendly, reducing chemicals, and conserving water.

The Pretreatment of Cotton Fabrics

Now, let’s take a quick sneak peek at the pretreatment of cotton fabrics;

Cotton-knitted fabrics undergo special pretreatment care to meet the highest quality and durability standards. These fabrics have unique characteristics, and when it comes to pretreating knitted fabrics, we have to consider their flexibility and structure. Unlike woven fabrics, knits are more pliable and can get loose easily

Scouring for knitted fabrics is done with a softer touch to avoid damage, and bleaching is customized based on the fabric’s final use. Lighter colors may require more intense bleaching to achieve the desired shade.

Alkali decrement is a crucial step in cotton knit pretreatment. It involves using concentrated caustic soda on the fabric, which significantly impacts the final result.

One of the critical benefits of alkali decrement is that it encourages the fibers to contract, resulting in a denser fabric. This denser fabric enhances the overall quality and improves its stretchability. So, this step is essential in increasing the fabric’s elasticity when creating snug and comfortable clothing.

Oh, you’ll love this part! After the initial treatments, it’s time to bring back the inherent softness of cotton knits. The fabric is dried out and given extra love with agents like paraffin emulsion to make it even softer.

But that’s not all! This softening step has another vital benefit. It ensures the fibers are strong enough for sewing, keeping those knit loops intact. This is key for ensuring the durability of the final product.

The Pretreatment of Ramie Textiles

Now, let’s look at different textiles and their pretreatment processes. First on the list is Ramie Textiles.

Ramie textiles have a unique pretreatment process tailored to ensure their quality. It is known for its durability and sheen, requiring meticulous pretreatment due to its natural makeup.

The first crucial step in pretreating ramie is degumming. This involves removing the gum from the fibers to clean them up for the following stages. Both biological and chemical methods are used in this critical step.

Next up is singeing, which plays a crucial role in enhancing the fabric’s quality. By eliminating fuzz and roughness from the surface, singeing smoothens the texture and prepares the fabric for dyeing. It’s a delicate process that involves careful application of heat.

Scouring is another essential step in the pretreatment of ramie. It tackles leftover impurities like pectin and wax, ensuring a deep clean for the fibers. Alkali solutions are commonly used in this phase to achieve optimal results.

Lastly, we have bleaching, the final hurdle in ramie’s pretreatment. This step aims to achieve the desired whiteness by removing the natural color and bringing out the fabric’s brightness. In this stage, the fabric has to be handled precisely with care.

The Pretreatment of Wool Textiles

The pretreatment of wool textiles is quite fascinating. Wool’s unique nature calls for tailored processes to ensure quality and long life. Let’s dive into the steps that make it happen!

First up is scouring, where raw wool undergoes a thorough cleaning. This step removes grease, dirt, and suit and can be done using water-based or solvent-washing techniques.

Next, we have fulling, crabbing, and thermo fixing. Fulling involves pressing wool fibers together to create a denser material. Crabbing helps prevent the wool from shrinking, while thermo fixing locks in the dimensions and feel of the fabric.

Anti-felting and anti-shrinking treatments are applied to preserve the quality of wool. These steps are crucial in maintaining the texture and shape of wool, ensuring that clothes made from it fit well.

Lastly, we have carbonization, vital in giving wool a deep clean. This process removes vegetable matter like leaves and twigs by treating the wool with acids at high temperatures.

The Pretreatment of Silk and Chemical Fiber Textiles

Let’s dive into the pretreatment of silk and chemical fiber textiles. It’s all about ensuring their quality and practicality.

Regarding silk, we focus on two critical steps: degumming and bleaching. Degumming is crucial for boosting silk’s gloss and softness by targeting sericin. And, of course, bleaching helps further enhance the silk’s brightness.

Moving on to artificial fibers, there are different pretreatment processes involved. We must roast, de-size, and sometimes bleach for artificial fibers like viscose. On the other hand, synthetic fibers follow a more straightforward path, with desizing and heat setting being the main steps. Heat setting is critical as it helps cement the fabric’s shape and improve its features.

In the pretreatment of synthetic fibers, each fabric receives a customized heat-setting treatment. This involves applying heat under tension to meet specific needs. What are the results? Wrinkle-resistant, stable, and refined synthetic fabrics.

Whew, Here are the key takeaways from the pretreatment of textiles:

– Textile pretreatment is essential for transforming raw materials into high-quality and functional textiles.

– Different fabrics require specific pretreatment techniques to achieve the desired results.

– Singeing is a process that improves fabric smoothness and appearance by removing unwanted fibers.

– Desizing is crucial for even dyeing and quality, as it removes sizing materials from the fabric.

– Scouring is a cleansing process that removes impurities from the fabric, ensuring quality production.

– Bleaching is used to achieve uniform fabric whiteness, employing specific chemical agents.

– Mercerizing is a treatment specifically for cotton, enhancing dye uptake and fabric strength.

– Cotton knits undergo gentler scouring and tailored bleaching processes to meet their unique requirements.

– Ramie textiles require specialized degumming and singeing processes to ensure quality.

– Silk and chemical fibers have tailored pretreatment steps, including heat setting.

OUTRO

Thanks for diving into the fascinating world of textile pretreatment with me! I hope you’ve gained valuable insights to take your understanding of fabric quality to the next level. Remember, by implementing comprehensive pretreatment practices, you can ensure that your textiles stand out in quality and performance.