What is an Infrared Sample Dyeing Machine?

The Infrared Sample Dyeing Machine is a device that applies infrared ray technology for dyeing small samples in the textile industry. This technique works by harnessing infrared energy and delivering it deep into the fabric fibers to improve dye penetration and fixation. The Infrared Sample Dyeing Machine is designed to perform dyeing tests in a small-scale laboratory environment to validate dyeing formulations and parameters for large-scale production.

The Significance of Infrared Sample Dyeing Machine

Infrared ray-assisted dyeing technology: An infrared ray is a kind of electromagnetic radiation, whose wavelength is below the visible spectrum. Infrared rays can penetrate the surface of the fabric and act directly on the inside of the fiber.

Heating the fabric fibers: Infrared dyeing prototyping machines transfer infrared energy into the fabric fibers by generating infrared radiation. This process causes the internal temperature of the fabric to rise, causing the fibers to absorb the energy and the temperature of fiber will rise.

Enhances Dye Penetration: The increased temperature inside the fabric helps to enhance the penetration of the dye into the fibers. As the temperature of the fibers increases, the dye can more easily penetrate the surface of the fibers and enter deeper into the fiber structure.

Improves Dyeing Quality: The action of infrared light allows dyes to penetrate more evenly and deeply into the fabric. Compared to traditional dyeing methods, infrared dyeing improves uniformity and penetration, resulting in more vibrant and long-lasting colors.

Temperature and time control: Infrared Sample Dyeing Machines are usually equipped with temperature and time control functions, which allow users to adjust the working parameters of the equipment according to different fabrics and dyeing requirements to achieve ideal dyeing results.

The usage of Infrared Sample Dyeing Machines is very wide, not only can it be used for textile dyeing, but also for dyeing rubber, plastic, and other materials. In addition, the infrared dyeing machine can also be used in printing, coating, and other industries, with good application prospects.

What are the advantages and disadvantages of different types of sample dyeing machines? How to choose?

Currently, there are three main types of sample dyeing machines in use, categorized by their mode of operation: elevating sample dyeing machines, rotating sample dyeing machines, and oscillating sample dyeing machines. The common features of those machines are:

Achieve a high level both on the temperature control of specific temperature degrees and the detection of constant temperature dyeing time, which can guarantee the reproducibility of dyeing Or high reference value of sample dyeing results.

Improve the work efficiency. The mechanical movement of the sample dyeing machine can ensure that the sample cloth in the dyeing cup is naturally turned, eliminating the labor of manual stirring, as well as the disadvantages caused by the differences in the frequency of manual stirring, stirring strength, and stirring uniformity to the dyeing. A sample dyeing machine can dye 12~24 samples at a time, which is twice as much as manual stirring dyeing. Therefore, the sample dyeing machine can not only improve the stability of small samples, greatly reducing labor intensity but also allows the operator to save more time and energy to do more things, thereby greatly improving work efficiency.

Higher dyeing accuracy and stability. By using those Sample Dyeing Machines, in the dyeing process, the changes in dyeing bath ratio and dye bath pH, additives concentration, etc. are relatively small. Therefore, compared with the electric furnace, and water bath dyeing, the test accuracy and stability, and the dyeing approximation between the sample and batch products are both higher.

Then, we talk about the unique features of those sample dyeing machines, including their advantages and disadvantages.

(1) Elevating type dyeing sample machine.

Elevating type dyeing sample machine is accompanied by polyester fabric dyeing processing. Its biggest features are.

① High pressure (0.39MPa), high temperature (140 ℃), it is suitable for dyeing under 130 ℃ .

② Not only has the constant temperature insulation function for a specific temperature, but also has a cooling function.

③ Dyeing under an enclosed environment, the dyeing bath ratio and pH value of dyeing bath are relatively stable.

④Whether it is a single dyeing cup or other dyeing cups dyeing together, the temperature uniformity of the dyeing solution is good, and the tuning frequency of dyeing samples is consistent. Therefore, it is suitable for the comparison test of the dyeing effect under the same temperature and time.

Water is used as the heat medium, and the dyeing cup is usually an open glass cup. Therefore, there is no problem of color bleeding pollution of sample cloth and pollution of the working environment. Application practice shows that the Elevating type sample dyeing machine is suitable for dyeing polyester and its blended and interwoven fabrics with dispersed dyestuffs under high temperature and high pressure, and also suitable for dyeing general cotton fabrics or viscose fabrics with direct dyestuffs and reactive dyestuffs at boiling temperature or below boiling temperature.

When dyeing nylon fabrics with neutral dyes and acid dyes, the uneven dyeing effect is easy to occur due to the slow speed of color absorption, which should be improved by the optimal selection of dyes, the proper control of dyeing temperature, and the correct application of auxiliaries.

Some fabrics are too light and weak because the sample cloth is tied on the hook in the shape of “回”, it is easy to stick together between layers, preventing the dye liquid from penetrating and flowing evenly in the sample cloth. Therefore, it is easy to produce cloudy color flowers.

In addition, there are two shortcomings: First, under high temperature and high-pressure dyeing, the dye cup can not be put or taken out at any time, even though room temperature and normal pressure dyeing, the dye cup can be taken out at any time, but the new dye cup should not be added in during the dyeing, because if the new dye cup is directly placed into a high temperature, the color will be dyed into the fabric with a poor uniformity; Secondly, under 130 ° C high-temperature dyeing, the seal on the lid is easy to leakage, it is very hard to reach the ideal dyeing temperature.

(2) Rotary sample dyeing machine.

There are two types according to the heating method: one is glycerin type and the other is infrared type.

Their common features are as follows.

① The dyeing cup is mounted on the turntable, and in the glycerin bath or infrared radiation, it makes 360°rotating movement, and its rotating speed is adjustable. Since the sample cloth inside the cup is rapidly turned with the dyeing liquid, the flow, and renewal of the dyeing liquid between the sample cloths are fast and uniform. Therefore, the leveling effect is good.

② The bath ratio of the rotary sample dyeing machine is small, generally (1:10)~(1:15) (the bath ratio of the Elevating sample dyeing machine is generally 1:30). The bath ratio is very similar to that of the jet overflow dyeing machine for mass production. It is also a big step closer to the large production bath ratio of the roll dyeing machine. This is very favorable to improve the reference value of sample dyeing.

③ Rotary dyeing machine, whether high temperature and pressure of 130 ℃ dyeing, or room temperature and pressure (below 100 ℃) dyeing, its dyeing cup in the dyeing are closed. This is perfect for the disperse dyes dyeing polyester, neutral dyes, acid dyes, or disperse dyes dyeing nylon. On the other hand, it is not suitable for reactive dyes, direct dyes, etc. dyeing cotton fabrics, or viscose fabrics that apply auxiliaries (salt, soda ash, etc.) in the middle of the dyeing process.

In other words, this kind of sample dyeing machine is not suitable for dyeing reactive dyes, direct dyes, and other dyes that need to be added more dyes in the middle of the dyeing process.

Even though there are infrared dyeing machines that can press the auxiliary solution into the dye cup with a syringe gun without opening the lid of the dye cup, the machine must be stopped in the middle of the process, and after each injection of a dye cup, it is necessary to rotate it immediately to 20~30s (to prevent the color bloom), so the dyeing temperature and dyeing time should be controlled, which means it is very poor in the practical application.

④ Glycerin bath dyeing machine has the advantages of easy operation, the dyeing cup can be added or taken out at any time, and different bath ratios can be used for dyeing in the same pot. However, its dyeing temperature is to detect the temperature of glycerin, so the temperature of the dye solution is not reliable enough. That is, there is a temperature difference between the dye solution and the glycerin bath. Moreover, the longer the glycerol bath is used, the higher the viscosity is, and the greater the temperature difference between the two (The viscosity of new glycerin is smaller, the heat transfer is faster and more uniform, so the temperature difference is relatively small).

When the temperature is kept constant for 5~10min, the temperature of the dyeing solution and glycerin bath can be balanced.

The detecting temperature of the infrared dyeing machine is closer to reality because the temperature probe is directly inserted into the dyeing cup. However, it has the following two drawbacks: firstly, the shape and size of the dyeing cups and the amount of dyeing liquid must be the same, otherwise, there will be a temperature difference between the dyeing cups; secondly, the dyeing cups can not be added or taken out at any time during the dyeing process, otherwise, it is difficult to control the dyeing temperature and time correctly.

⑤ Whether it is a glycerin-type sample dyeing machine or an infrared-type sample dyeing machine, the problem of dye adsorption on the sealing ring of the dyeing cup and contamination of the dye solution or the sample cloth exists. Application practice shows that, whether it is dyeing light colors or dark colors (especially disperse dyestuff dyeing polyester at a high temperature of 130 ℃), the sealing ring of the seepage of the color pollution phenomenon generally exists. Therefore, the cleaning and updating of the sealing gaskets of the dyeing cups should be frequent, otherwise, it will result in the “distortion” of the color light of the sample cloth.

The general rotary sample dyeing machine is suitable for high-temperature and high-pressure dyeing of dispersed dyestuffs, and it can also be used for dyeing at or below boiling temperature. Among them, the glycerin-type dyeing machine, due to the environmental pollution of fumes, does not meet the requirements of environmental protection, in recent years the user has been gradually reduced; infrared-type dyeing machine, due to the accurate monitoring of dyeing temperature, dyeing time, rate of heating, rotating speed, and a relatively high degree of automation, the application range is increasingly expanding.

(3) Oscillating type sample dyeing machine.

How does this dyeing machine work? The 250L capacity triangular flask with dye solution and sample cloth is embedded in the “finger holder” of the dyeing machine, the bottom of the flask is immersed in water, and the flask swings left and right along with the machinery, and the frequency of the swing and the temperature of the water bath are adjustable and self-controlling. The dyeing liquid in the flask and the sample cloth are dyed in the oscillation. The main features of the machine are as follows:

① It replaces manual stirring with mechanical oscillation to realize even contact between the dyeing solution and sample cloth to achieve an even dyeing effect.

② It eliminates all the drawbacks brought by manual stirring to the dyeing quality.

Replacing the open dyeing cup with a triangular flask has the advantages of less splashing of the dyeing solution, less evaporation of water, visualization of the dyeing process, and the application of auxiliaries in the middle of the dyeing process can be done.

The dyeing material is in a completely free state in the dyeing solution. There is no need to fix the dyeing material in the dyeing solution, and there is no need to seal the dyeing material with a cover. Therefore, its operation is simpler than that of the rotary type and elevating type, and there is no problem of contamination by the cup and cover gasket.

During the dyeing process, the cups can be added or removed at any time. Therefore, it can be used by more than one person and improve the utilization rate of the sample dyeing machine.

The biggest disadvantages are two: firstly, the mechanical noise is big, and the noise pollution in the working environment is heavy; secondly, during the dyeing process, due to the need for additional auxiliaries, observation of the dyeing status, and the alternation of dyeing flasks being put into and taken out of the dyeing machine, the upper cover of the dyeing machine often needs to be opened, and so the machine is of the half-open type. On the one hand, the steam overflow is serious in winter, which has a great influence on the working environment; on the other hand, the temperature of dyeing liquid in the flask can not reach 98℃, but only 93℃. Therefore, for some high-temperature dyeing dyestuffs, such as neutral dyestuffs, acid dyestuffs, neutral color-fixing reactive dyestuffs, as well as some direct dyestuffs, etc., the final dyeing rate will be reduced due to the low dyeing temperature.

What are the features of a good quality sample dyeing machine

In general, an excellent sample dyeing machine should have the following basic conditions:

① Uniformity should be good, not easy to produce a color bloom.

② The bath ratio of sample dyeing should be small and as close as possible to the bulk. Moreover, the stability of the bath ratio is required to be good.

The detection of dyeing temperature should be accurate. The rate of heating and cooling should be controllable.

④ There should be a stirring function for dyeing samples, and the stirring frequency should be flexible and adjustable.

⑤ The dyeing machine should have an automatic alarm device for the time monitor.

⑥ It should be convenient to add materials, easy to operate, and safe enough.

⑦ There is no color staining and stringing phenomenon on the dyeing samples, and there is no pollution to the environment.

⑧ The working efficiency can be improved, and the dyeing machine could be applied to various samples. And The dyeing should have good reproducibility.

What do the customers care about when they choose a sample dyeing machine

Printing and dyeing factories are usually concerned about the following aspects when dyeing samples:

Color Accuracy: The first concern of the printing and dyeing factory is whether the color of the sample dyeing is consistent with the design or the color required by the customer. Color accuracy directly affects product quality and customer satisfaction.

Dyeing Uniformity: The fabric factories are concerned with dyeing uniformity to ensure that the color is consistent across the entire fabric surface. Perfect dyeing is an important indicator of product appearance and is important for consistency in mass production.

Color Fastness: Color fastness refers to whether the fabric can maintain the firmness of dyeing under washing, exposure, and other conditions. Printing and dyeing factories are concerned about the color fastness of dyeing to ensure that the product will not fade in actual use.

Dyeing Costs: Dyeing factories need to consider the cost of dyeing, including the cost of dyestuff, energy consumption, labor costs, and so on.

Dyeing Efficiency: Sample dyeing is part of the production process, dyeing factories are concerned about the production efficiency of dyeing, and try to complete the sample dyeing in a shorter time, to respond more quickly to customer demand and new product development.

Environmental Requirements: More and more dyers are focusing on environmental factors in the dyeing process. The use of environmentally friendly dyestuffs, reduction of wastewater discharge, and sustainable use of energy are the concerns of printers when dyeing samples.

Customer Satisfaction: The results of sample dyeing are directly related to customer satisfaction. Printers strive to ensure that sample dyeing meets customer expectations to build long-term relationships.

Technological Innovation: Some printing and dyeing factories are concerned about adopting the latest dyeing technology, such as infrared dyeing, to improve dyeing results, reduce energy consumption, and remain competitive in the market.

What is the application of an Infrared Sample Dyeing Machine?

Infrared Sample Dyeing Machines apply to many industries, mainly in the textile and dyeing and finishing fields are widely used. The following are the industries and products to which the infrared dyeing machine is applicable:

Textile Industry:

Textile Manufacturers: Infrared Dyeing Samplers are widely used in textile manufacturer’s laboratories to conduct sample dyeing tests to verify dyeing results.

Garment Manufacturing: Used for dyeing small samples of garments to evaluate the performance in terms of color, uniformity, and color fastness.

Home textile: For bedding, curtains, sofa covers and other home textile dyeing small sample preparation.

Dyeing and finishing industry:

Dyeing and Finishing: An infrared Dyeing Sample Machine can be used in dyeing and finishing factories to validate the dyeing scheme and adjust the dyeing parameters.

Dyestuff producers: Dyestuff producers can use an infrared dyeing samples machine for formula testing and color mixing of dyestuff.

R&D Laboratory:

Textile R&D Laboratory: For the development of new materials, processes, and dyestuffs for textiles and the validation of dyeing solutions.

Dyestuffs Research Laboratory: For performance testing of dyestuffs and development of new dyestuffs.

Educational Institutions:

Textile and clothing colleges and universities: For experimentation and teaching of students, to help them understand dyeing technology and practical application.

Medical supplies manufacturing: for dyeing medical textiles, surgical clothing, and other small samples to ensure that the color and color fastness meet the requirements.

Industrial use: for special industrial fabric dyeing, such as protective clothing, industrial filter media, etc..

The infrared dyeing sample machine is usually applied to various fabric types, including natural fibers (such as cotton, hemp, and silk), synthetic fibers (such as polyester, and nylon), blended fabrics, and so on. It provides a fast and accurate solution for small sample dyeing in various industries, which helps to speed up the product development and production process while improving dyeing results and color fastness.

Common brands of Infrared Sample Dyeing Machines on the market

Mathis AG (Mathis)

Mathis AG is a Switzerland-based company that specializes in the manufacturing of textile laboratory equipment and machinery. Their products include infrared dyeing sample machines to provide small sample dyeing and laboratory testing solutions.

Goller

Goller is a Switzerland-based company specializing in the manufacture of textile dyeing and coating equipment. They offer a wide range of dyeing and finishing equipment including infrared dyeing small sample machines.

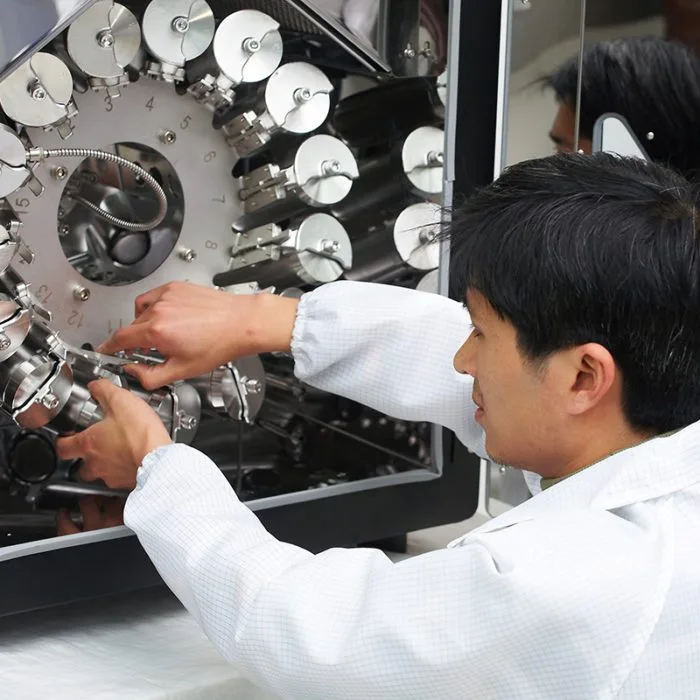

ChiuVention

ChiuVention is designed by the German Team and its products are manufactured in China. ChiuVention offers a wide range of textile testing equipment including an infrared sample dyeing machine. They are well known in 42 countries and regions.

Sedo Treepoint

Sedo Treepoint is a German company specializing in textile laboratory equipment, including infrared dyeing samplers. Their products have a wide range of applications in laboratory research and sample preparation.

Montech

Montech is a Swiss-based company specializing in the manufacture of textile dyeing and finishing equipment and machinery. They offer a range of laboratory equipment including infrared dyeing machines for small sample dyeing.

Brief Introduction of InfraDye Infrared Sample Dyeing Machine

The infrared sample dyeing machine is creatively set up with a series of tilted cup sleeves that can accommodate heat-conducting oil.

The test dyeing cups are inserted in the sleeves, allowing the cups to be kept tumbling at a similar vertical angle during the rotation process, which completely simulates and reproduces the field production pattern. The infrared lamp does not directly heat the dye cup, but the heat-conducting oil, so the temperature difference between cups is avoided,

and the temperature control probe only needs to directly detect the temperature. As for the cooling method, convection forced air cooling is considered which can fully meet the dyeing and color-matching experiments of each printing and dyeing factory; segmentation temperature sampling test; segmentation, even dyeing, penetration test; acidity, temperature, bath ratio differences on the dyestuff absorption rate test; concentration and other tests, etc. Additionally, the manufacturer-ChiuVention can make different specifications of dyeing cups according to customers’ needs.

The Features of the InfraDye Sample Dyeing Machine

Smart temperature control algorithm

achieving different test temperatures, suitable for all kinds of dyeing at room temperature and high temperature.

Multiple dyeing solutions can be realized at one time: different specimens can be dyed in different cups.

Smart instrument

Can be connected through Wi-Fi with the SmarTexLab App installed in smartphones, set parameters, monitor the test status, receive equipment warning reminders, replenishment reminders, etc., and share test results with one click.

User-friendly, convenient, and efficient

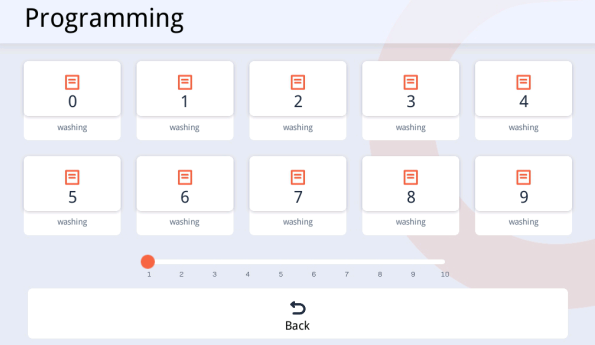

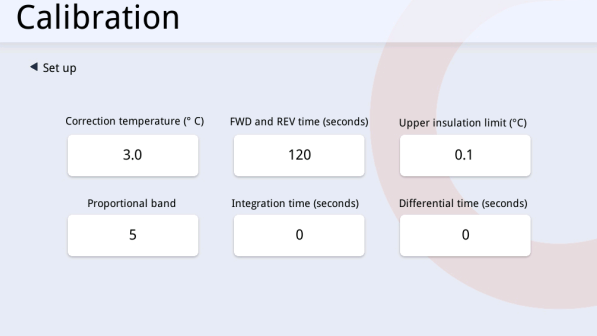

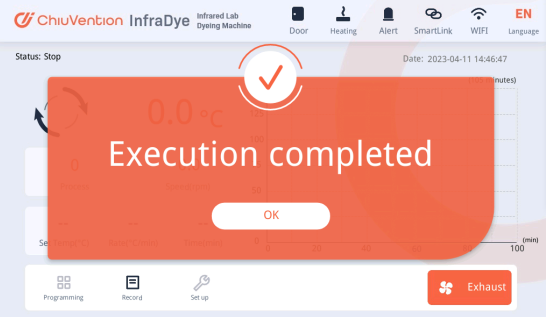

microcomputer control, a simple operation, automatically retains the current data in case of power failure, the running process can be edited, and the buzzer automatically alerts after the test is completed.

Stable, durable, and noiseless

the transmission mechanism is upgraded to rotary operation, which is more stable, more durable, and noiseless.

Multiple safety protection

such as an over-temperature alarm function and automatic stop of the rotating cup holder when the door is mistakenly opened.

Temperature calibration function can avoid the temperature difference caused by the aging of the probe.

Longer service life

Solid state relay control electric heating, no mechanical contact, long service life. The mechanical shell is made of a stainless steel powder coating process, the mechanical interior is made of high-quality SUS304 stainless steel, and the dyeing cup is made of SUS316, which is durable.

The Specification of InfraDye Infrared Lab Dyeing Machine

Test temperature range: room temperature (greater than 0 ° C) 0 ~ 140 ° C

Temperature control range: room temperature (greater than 0 ° C) 25 ° C ~ 140 ° C

Heating temperature control speed: 0.1 ℃ / min ~3 ℃ / min

Temperature control accuracy: Isothermal state ± 0.5℃/min

Temperature control mode: optimized automatic control

Rotational speed: 0 ~ 50 rpm (adjustable)

Working environment

Working temperature ≤50 ℃.

Relative humidity ≤90%RH

Power AC230V 50HZ 32A

Weight 145kg

Dimension 710*840*750mm (D*W*H)

The Machine appearance and interface of InfraDye

This machine has combined the general advantages of infrared and traditional glycerin-proofing machines and adopted a high-temperature resistant machine door sealant that is easy to use. The cage can insulate heat-conducting oil so that the temperature of the door will not be affected by the next use.

Display Main Interface

Those are parts of the interface screenshots. For more information about this machine, you can contact the ChiuVention Team.

And warmly welcome to discuss more topics of fabric sample dyeing machines with us.