The Martindale abrasion tester is used to measure the abrasion resistance of home textiles and upholstery. It is the simulation of seat cover wear where the fabric undergoes rubbing on a daily basis use. The standard for abrasion resistance is ISO 12 947. Let’s start with what is Martindale Test.

Martindale Test

The specimen is cut to 38 millimeters in diameter using a sample cutter for the Martindale test. The sample is taken from the left, middle, and right of the fabric. The specimen is fixed on the holder friction head and tightened by the nut.

The friction lining of the failed fabric head is fixed on the friction table. After that, the sample width holder is fixed on the friction table with nine kilopascals or one kilopascal’s hammer and at the sample face down.

Let’s start testing. You can see each test station is working according to the Lissajous trajectory and strength of the sample. The instrument can be suspended at different times to observe the friction of the sample.

Martindale Friction Table

Finally, we get the testing results. The result evaluation should be based on at least two independent units of fabric that are completely broken.

Martindale Fabric Abrasion Resistance

The Martindale fabric abrasion resistance is basically the ability of a fabric that how much it resists to surface loss when a fabric is being rubbed with other material.

Factors Affecting Abrasion Resistance

The important factors in fabric abrasion are as follows:

- Kind of abradant

- Direction of force

- Amount of abrasion force

- Tension on the substrate

- Whether the material is wet or dry

Goal of Abrasion Testing

There are three different endpoint results in abrasion testing. One endpoint for evaluation is cycles to failure. Under this approach, the fabric is subjected to abradant until the destruction of the construction is achieved, either by breaking the yarn or getting a hole.

Another goal in abrasion testing is the percentage loss in strength of the material before and after a specified number of cycles of testing. The third option for abrasion testing is the evaluation of any visual change in the surface of the specimen.

In this scenario, there may be a loss of color distortion of the surface or both with regard to surface change. The abrasion may cause a loss or increase in luster hairiness, loss of surface pile matting pilling, and other forms of distortion.

With all these tests performance standards are expressed as minimums. In reporting the data the type of test performed, the instrument used, the testing lab conditions and other pertinent information are also listed.

Types of Abrasion

Flex and flat abrasion are the two most used types of abrasion in textile laboratories.

Flex Abrasion

Flex abrasion occurs when a material is bent around a braiding surface. The action of the material around abradant is typical of most, and use applications in those fabrics are typically not used in a flat condition.

The flex abrasion test is designed to determine the abrasion resistance of woven or nonwoven textile fabrics by flexing the fabric on a specially designed test instrument. Fabrics that have excessive stretch do not perform properly with this test. The values are expressed in Si or inch-pound units.

Flat Abrasion

Flatten abrasion results from rubbing the specimen against a flatter braiding surface. This type of abrasion would be similar to pants sledding across a chair.

The use of a tablecloth or a bed sheet edge abrasion occurs when a fabric is folded around itself or when multiple layers of fabric are fused. Examples are cuffs of shirts and pants, waistbands, hemmed areas of a garment, creases, and pleats.

The abrasive force is applied directly to the edge of multiple layers most apparel and home furnishings are subjected to at least two of these types of abrasion. However abrasion testing instruments apply only one type of abrasion.

Martindale Test Limits in High-Performance Fabrics

The Martindale tester determines the abrasion resistance of textiles. In this test, the fabric that has to be checked is abraded on the surface of an abradant material. The fabric shows the wear behavior after a specific number of rubbing cycles.

High-performance and durable textiles show better abrasion resistance. The Martindale abrasion results are based on the number of rubs.

The fabric that will stand its condition and resist loss of surface after a comparatively higher number of cycles will be considered as good quality regarding abrasion.

High-performance fabrics are used at commercial and industrial levels. The textiles that are used for private purposes can withstand 10, 000 – 15, 000 rubs. The fabrics that are used at commercial levels in hotels and public places should withstand up to 25,000 rubs.

Heavy-duty places require more durable clothes, which is why fabric for such places as airports, cinemas, and hospitals uses clothes up to fifty thousand rubs.

The emergency service places require fabrics that withstand more than 1 00,000 rubs. This type of fabric is used where extreme performance is demanded, like military or police.

The Origins of the Martindale Method

The Martindale abrasion instrument was developed 83 years before 2025. This instrument was built by Dr. James G. Martindale who was a British engineer. James G. wants to develop a standard procedure for determining fabric wear resistance.

He gave a testing method by using the friction factor to indulge wear in fabric. The Martindale testing method got attention in 20 the century when a demand was raised for determining the wear resistance of fabric in the textile, upholstery, and automotive industries.

In 1942 the Martindale testing instrument became the favorite choice due to its accuracy and consistent results over repeated trials. At that time it was the best option to meet the demand of customers regarding abrasion.

Martindale Abrasion Tester Vs Wyzenbeek

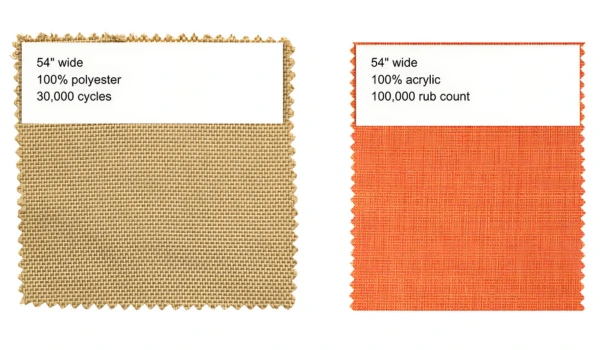

Have you ever noticed on an upholstery fabric label there are sometimes words like rub count or cycles and there are these big numbers next to them and you’re wondering what all of that means?

Fabric labels, including upholstery labels, always show information like how wide the fabric is or what the fabric is made of, but sometimes, on upholstery labels, there is a term like rub count or cycles and a significant number next to them.

What those refer to are different tests that were carried out on that upholstery fabric to let us know how durable is? What those specifically refer to is rub count, and cycles have to do with resistance to abrasion tests.

The American Society of Testing and Materials is an organization that recognizes all of the different testing methods that are used on a variety of products that we use in our lives.

We’re talking about rub count and cycles on a fabric having to do with abrasion resistance. Two main tests are carried out on upholstery fabric. Let us know how durable they are. Those two tests are called the Wyzenbeek test and the Martindale test.

It will have a different rating for the durability of the fabric. The first test that we’ll talk about is the Wyzenbeek testing method. This is where we get ratings; it says rub count, rubs, or double rubs.

Wyzenbeek Testing Method

What happens in this test? A piece of fabric is placed in this specific machine and an abradant either another fabric or another type of material is rubbed up against that fabric.

The Abradant is placed on a cylinder, and the cylinder goes back and forth to rub over that fabric. Each back-and-forth rubbing is considered a cycle, and actually, they call that a double rub because it goes back and forth two times over the fabric.

When they get a rating for a fabric that’s where you’ll see double rubs and how many double rubs that fabric went through before it starts to break down. Those ratings range from thousands of times that the fabric is rubbed up against to see how long it will stand up.

So when you see rub counts or double rubs or rubs, what that’s referring to is this Wyzenbeek testing method for resistance to abrasion.

Martindale Testing Method

The second test, the Martindale test, is where they get a rating that is based on Cycles. What happens in this testing method?

In this method, the fabric to be tested is placed almost on like a disc. Then, an abradant, whether that’s another material or another type of fabric, is placed over that fabric to be tested. It’s rubbed up against the fabric in a circular motion.

It’s a different type of motion than the Wyzenbeek, and it’s tested for the same thing to see how long it resists abrasion.

Its rating is based on how many thousands of times that fabric can stand up to that circular motion rubbing up against the fabric to see how well it will last before it starts to wear out.

The ratings that you receive from the Martindale testing would say Cycles, so you know a fabric went through 30,000 Cycles before it started to wear down.

Both of these testing methods are used not just on upholstery fabric but also on all types of fabric even apparel fabric because what those testing methods let us know is you know how durable that fabric is going to be and also what would be the appropriate use for that fabric.

Fabric manufacturers that produce textiles for the commercial environment, those environments where the public would be using these materials, may decide to test their fabric using the Martindale method.

It may better simulate sitting down and getting up and standing on their upholstery fabric when it’s on a sofa or chair in a busy public area.

Range of Testing Results

There’s a range of these different ratings to let us know what the appropriate use of that fabric would be.

In general, when we’re talking about upholstery fabrics for our homes there is usually a range between 15,000 double rubs for a Wyzenbeek testing rate and 20,000 rubs for a Martindale testing method.

Let us know if that would be good for light upholstery use, so that could mean a little bench that you sit on to put your shoes on every morning and take them off in the evening. It’s not used a lot throughout the day, and that would be an appropriate use.

When you start to get into higher numbers, you know, 30,000 double rubs for a Wyzenbeek or 40,000 Cycles in the Martindale testing method. That’s where those ratings tell us that those Fabrics would be appropriate for heavier use.

That would be on a sofa that you use every day, and you have a very active family, so you want something that’s going to be super durable.

ASTM D4966: A Benchmark or an Outdated Measure

ASTM D 4966 standard determines the fabric’s durability and wear resistance. It is still widely used in textile laboratories as a prominent standard for determining abrasion resistance. Each instrument and standard has some advantages and some limitations.

ASTM D 4966 Tester

Advantages

We have to understand that every standard has its specialties. ASTM D 4966 is still used as a basic standard of wear resistance in textile, upholstery, and automated industries due to its testing behavior that is very close to real-world conditions.

This test gives a satisfactory indication of high-performance fabrics in case of excessive daily use. The other benefit is that this test has now been recognized worldwide, easily understandable across different countries, and is acceptable, which makes it easy for manufacturers to use.

Limitations

Every testing method has some limitations, which we should understand. The ASTM D 4966 standard operates on circular motion for evaluating abrasion resistance. This thing lemmatizes the application according to real-world conditions.

In the real world, there is not always a circular resistance that a fabric has to face. This thing limits the use case of ASTM D 4966.

The second thing is due to advancement; there are more strict standards for determining abrasion resistance, like ASTM D3884 (Taber Abrasion) or ISO 12947, which works on different perspectives of wear.

In conclusion, ASTM D4966 is still considered a benchmark standard in textile industries, but it lacks some frictional behavior, which can be covered by using other standards.

Pilling Resistance Test and Surface Wear: What’s more important?

Firstly, we see the difference between pilling and wear resistance.

The pilling forms small balls on the surface of the fabric due to the entanglement of fabric hairiness. At the same time, wear resistance is considered as the ability of fabric to resist rubbing.

The testing standards for pilling are ASTM D497 & ASTM D3512, while for wear resistance, ASTM D4966 & ASTM D3884.

If we say which parameter is most important, then it depends upon the product usage. If we require a fresh and aesthetic look, the pilling is more critical, like in apparel and fashion clothes.

For textile products that are expected to have good wear resistance, like upholstery, then surface wear is more important. Overall, both parameters have their importance according to the use case.

The Impact of Martindale Fabric Scores on Consumer Perception

The Impact of Martindale Fabric Scores on Consumer Perception

The Martindale abrasion rating is just a number for a marketing stunt, or does it predict the product’s durability? Let’s look at this concern.

The instrument operates on the principle of rubbing in a circular motion, and results are given in a number of rubs or cycles. Textile products have different abrasion resistance properties according to their end-use.

We have to check how many rubs a fabric can withstand without breaking down the fabric or damaging the fabric’s surface.

Here is the table that shows the Martindale rating for different types of products according to their end-use case.

| Sr # | Number of Rubs | Application |

| 01 | 10,000–15,000 | Domestic |

| 02 | 15,000–25,000 | General Domestic |

| 03 | 25,000–50,000 | Light Commercial |

| 04 | 50,000+ | High Traffic areas |

The consumer thinks that fabric with a higher number of rubs is more durable, which gives him an idea and influence on purchasing the more significant number of Martindale ratings. In this way, the Martindale fabric score is used as a marketing tool.

But here, we have to understand that this number of rubs is just one factor that is performed on the instrument in ideal conditions. There is no involvement of other actual world conditions like UV exposure, sunlight, excessive washing, and other degradability parameters.

It might be possible that two fabrics with more than 50,000 + show different behaviors to abrasion due to various environmental conditions or fabric configuration and processing.

Martindale Abrasion Tester Price & Innovation: Are Expensive Machines Always Better?

In the market, there is a variety of abrasion testers that have a range of friendly budgets to high-class instruments.

Here comes confusion in technicians’ minds that either the most expensive machine is the best for use or the same testing can be done with the low-budget instruments. So, let’s have a look at this mindset.

Firstly, we will see what types of functions are present in expensive Martindale testers.

The most expensive tester will be the latest version with all smart functions like automation, digital display, and checking multi-fabrics at the same time to save time. It is built with high-quality and durable material.

Now the second question is whether only the expensive machine will be suitable for working. Here, you have to understand that the Martindale testing principle will be the same inexpensive and friendly budget instruments.

You have to consider the instrument according to requirements. For example, e-automation is not required in small-scale industries whereas large-scale industries are required due to excessive load of working.

The expensive ones will require costly maintenance and a trainer to fix the issue, while the low-budget instruments can be handled through lab technicians and will have low-cost maintenance.

The expensive Martindale testers are energy efficient, use IOT technology, and cloud tracking technology for remote monitoring, and do innovative testing with additional features of predicting the material performance

Conclusion

Martindale abrasion testing is a widely used parameter for determining fabric abrasion resistance. It is still considered the benchmark standard for testing.

This instrument needs to overcome some limitations, like the application of UV and the addition of other environmental conditions during the abrasion. This will help to get results that are more reliable and closer to real-world situations.

FAQs

Why is the Martindale test performed?

The Martindale abrasion test is performed to measure the abrasion resistance of home textiles and upholstery. It is the simulation of seat cover wear where the fabric undergoes rubbing on a daily basis use. The standard for abrasion resistance is ISO 12 947.

How was the sample prepared for the Martindale test?

The specimen is cut to 38 millimeters in diameter using a sample cutter for the Martindale test. The sample is taken from the left, middle, and right of the fabric.

Which factors affect abrasion resistance?

The critical factors in fabric abrasion are the kind of abradant, the direction of force, the amount of abrasion force, the tension on the substrate, and whether the material is wet or dry.

What is the goal of abrasion testing?

The goal in abrasion testing is the percentage loss in strength of the material before and after a specified number of cycles of testing. The evaluation of any visual change in the surface of the specimen is considered.

Who developed the Martindale tester?

The Martindale abrasion instrument was developed 83 years before 2025. Dr. James G. Martindale, a British engineer, built this instrument. James G. wants to establish a standard procedure for determining the fabric wear resistance.

Which things are to be improved in Martindale tester?

This instrument needs to overcome some limitations, like the application of UV and the addition of other environmental conditions during the abrasion. This will help to get results that are more reliable and closer to real-world situations.