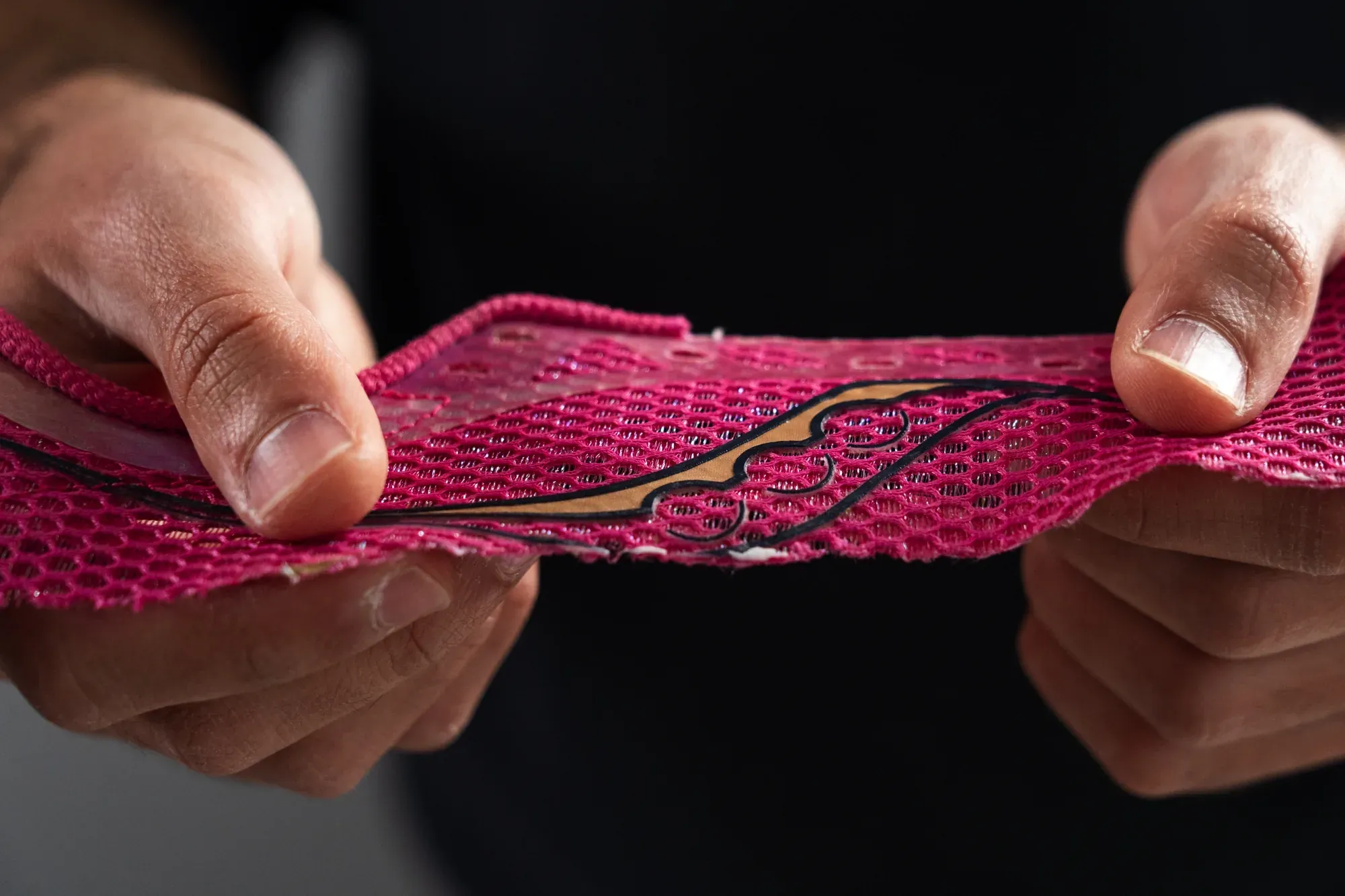

In the highly competitive and ever-evolving footwear industry, innovation serves as the cornerstone of success. The remarkable advent of Flyknit technology has redefined the boundaries of athletic footwear design. Since its inception by Nike in 2012 through the ingenious adaptation of computerized flat knitting techniques, Flyknit uppers have swiftly permeated the global sneaker market.

Their allure lies not only in their ultra-lightweight nature but also in their ability to conform impeccably to the foot’s contours, providing unrivaled breathability and comfort. However, this pursuit of minimalism in design has led to a reduction in material thickness, inadvertently posing challenges to their wear resistance. This has, in turn, spurred an urgent need for meticulous research into the most suitable testing methodologies. In this comprehensive exploration, we embark on a journey to dissect the wear resistance test methods of three distinct thicknesses of Flyknit upper materials, leveraging advanced testing equipment such as the Martindale Abrasion Tester and considering crucial standards like Martindale Abrasion Test Standards.

Different Types of Abrasion Resistance Test Methods on Flyknit Upper Materials

Selection of Test Methods

Martindale Abrasion Resistance Method

The Martindale Abrasion Tester is a stalwart in the textile testing arena within China, frequently employed for evaluating pilling and abrasion resistance. The national standard GB/T 3903.16—2008, which aligns with ISO 17704:2004, meticulously delineates the protocol for applying this method to footwear materials.

Testing Principle

Under a constant pressure, the specimen is subjected to the rubbing action of a standard friction fabric or sandpaper. The resultant Lissajous figure motion between the abrasive and the specimen engenders friction from all directions. Subsequently, the specimen’s discoloration and damage levels are appraised after a predefined number of rubbing cycles. This process is a key application of the Martindale Abrasion Test Method, which adheres to strict Martindale Abrasion Test Standards.

Testing Procedure

We carefully install the wool felt and friction fabric on the grinding table, then attach the polyurethane foam and specimen to the grinding head. After assembling the components, we mount the grinding head on the instrument, ensuring the specimen makes contact with the abrasive at a precisely calibrated pressure of (12 ± 0.2) kPa. We then activate the instrument and complete the specified number of friction cycles. Once the process is finished, we remove the grinding head and inspect the specimen’s damage under controlled lighting. We assess discoloration using the GB/T 250—2008 grey scale and evaluate pilling according to GB/T 4802.1—2008. Finally, we qualitatively categorize the extent of the damage, ranging from none to complete. This procedure is commonly executed using the Martindale Tester or Martindale Test Machine, which are integral components of the Martindale Test Equipment

Parameters

The specimen, with a diameter of 38 mm, is prepared in duplicate for each fabric type. The test is conducted under dry friction conditions, with a pressure of (12 ± 0.2) kPa. For wool friction fabric, the friction count is set to 25,600 and 51,200 cycles, while No. 600 water sandpaper is tested with 100 and 200 cycles. These parameters are precisely calibrated according to Martindale Abrasion Test Standards to ensure accurate and reproducible results.

Testing Instrument

The Smartindale Martindale Abrasion & Pilling Tester Martindale Abrasion Tester, crafted by ChiuVention,serves as the testing apparatus. For those seeking to acquire such a tester, the Martindale Abrasion Tester for Sale market offers various options, with prices influenced by factors such as features and brand reputation.

Taber Abrasion Resistance Method

This method is underpinned by several key standards, including GB/T 30314—2013 (equivalent to ISO 5470—1:1999), QB/T 4545—2013 in China, and ASTM D3884—2009(2017) in the United States.

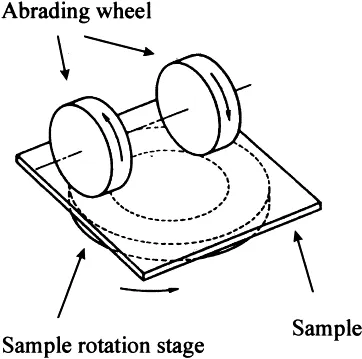

Testing Principle

The specimen is positioned on a rotating platform, where two counter-rotating friction wheels, each with a distinct orientation, apply rotational friction under a specific load. This process etches a circular wear pattern onto the specimen. Post a predetermined number of rotations, the specimen’s wear is quantified either by visual inspection of its appearance or through mass loss calculations.

Testing Procedure

We adhere a 1-mm thick specimen fixing piece to the reverse side of the specimen to preserve its structural integrity. Next, we carefully center and flatten the specimen on the turntable. We mount the designated H18 grinding wheel onto the instrument’s rocker arm and adjust the load to 1000 g using calibrated weights. After priming the revolution counter, we gently lower the grinding wheel onto the specimen and activate the instrument to complete the set number of revolutions. Once finished, we retrieve the specimen and examine it for damage under standardized lighting. We assess discoloration and pilling using the previously mentioned standards.

Parameters

The instrument rotates at a speed of (72 ± 5) r/min, and the specimen, with a diameter of (106 ± 1) mm and a 6-mm center hole, is cut into two pieces. The test parameters include 300 and 500 rotations.

Testing Instrument

The 5155 ABRASER Taber Abrasion Tester, manufactured by TABER Company in the US, is utilized for this test.

Stroll Abrasion Resistance Method

This method follows FZ/T 01121—2014 in China and ASTM D3886—1999(2015) in the US.

Testing Principle

We put the specimen on an inflatable rubber diaphragm, maintaining a stable air pressure, and use a specific grade of sandpaper to create friction. After completing the set number of rubbing events, we visually inspect the specimen to assess its wear.

Testing Procedure

We install the flat grinding fixture onto the rotating platform and place the specimen, with its testing surface facing up, between the rubber sheet and the fixture. We securely clamp No. 600 water sandpaper into the abrasive holder. The air pump is activated to establish and maintain the specified inflation pressure. We position the friction weight on top of the friction plate, which is then lowered to ensure contact between the sandpaper and the specimen. The instrument runs until it completes the designated number of cycles. Afterward, we remove the specimen and inspect it for damage as previously described.

Parameters

We cut each fabric specimen, with an area of 100 cm², into two pieces. Set the reciprocating speed to (125 ± 5) times/min, with a stroke of (25 ± 2) mm. Then, maintain the inflation pressure at 28 kPa and the friction pressure at (450 ± 5) g. We use No. 600 water sandpaper as the abrasive and conduct the test for 200 and 300 cycles.

Testing Instrument

The CAT-125 Multi-purpose Abrasion Tester, by Daiei Company in Japan, can conduct these tests.

Selection of Specimens

We select three representative Flyknit upper specimens, ranging from thin to thick, to provide a comprehensive analysis. See Table 1 for defining and detailed parameters.

| Specimen Number | Thickness/mm | Unit Area Mass/(g/m²) |

| 1# | 1.0 | 323 |

| 2# | 1.5 | 482 |

| 3# | 2.1 | 677 |

Table 1 Main parameters of the three specimens

Conditioning and Test Environment

We condition the specimens in an environment maintained at (20 ± 2) °C and (65 ± 4)% relative humidity for 24 hours before conducting all tests under these stable conditions.

Testing Results Displained

To enable a thorough comparison and detailed analysis, we present the test results of all three methods in a consistent format, focusing on discoloration, pilling, and wear degree, as shown in Table 2.

| Method | Martindale Method | Martindale Method | Martindale Method | Martindale Method | Taber Method | Taber Method | Stroll Method | Stroll Method |

|---|---|---|---|---|---|---|---|---|

| Specimen | Wool Friction Fabric | Wool Friction Fabric | No. 600 Water Sandpaper | No. 600 Water Sandpaper | ||||

| Number | 25600 times | 51200 times | 100 times | 200 times | 300 times | 500 times | 100 times | 200 times |

| 1# | Discoloration 4 – 5 grades, pilling 2 grades, surface completely slightly worn | Discoloration 2 grades, pilling 4 grades, surface completely worn | Discoloration 3 grades, pilling 4 grades, surface completely worn | Discoloration 2 grades, pilling 4 grades, surface completely worn | Discoloration 4 – 5 grades, pilling 2 grades, surface almost completely worn | Discoloration 3 grades, pilling 4 grades, surface almost completely worn | Discoloration 2 – 3 grades, pilling 3 – 4 grades, surface almost completely worn | Discoloration 2 – 3 grades, pilling 3 – 4 grades, surface almost completely worn |

| 2# | Discoloration 3 grades, pilling 3 grades, surface slightly worn | Discoloration 4 – 5 grades, pilling 3 grades, surface almost completely worn | Discoloration 4 – 5 grades, pilling 4 grades, surface almost completely worn | Discoloration 4 grades, pilling 4 grades, surface almost completely worn | Discoloration 3 – 4 grades, pilling 3 grades, surface severely worn | Discoloration 3 – 4 grades, pilling 3 grades, surface completely worn | Discoloration 2 – 3 grades, pilling 3 – 4 grades, surface severely worn | Discoloration 2 – 3 grades, pilling 3 – 4 grades, surface severely worn |

| 3# | Discoloration 4 – 5 grades, pilling 4 grades, surface moderately worn | Discoloration 4 – 5 grades, pilling 3 grades, surface moderately worn | Discoloration 4 grades, pilling 3 grades, surface moderately worn | Discoloration 4 grades, pilling 3 grades, surface moderately worn | Discoloration 3 – 4 grades, pilling 3 grades, surface moderately worn | Discoloration 3 – 4 grades, pilling 3 grades, surface moderately worn | Discoloration 4 grades, pilling 4 grades, surface moderately worn | Discoloration 3 – 4 grades, pilling 4 grades, surface moderately worn |

Table 2 Test results of wear resistance of three kinds of specimens

Discussion and Analysis

Discussion on the Applicability of Test Methods

Martindale Abrasion Resistance Method

Advantages

The Lissajous curve motion endows the Martindale Abrasion Tester with excellent friction anisotropy and a broad friction zone, ensuring high test repeatability. The ability to interrupt the test and examine the specimen at any juncture is a significant boon. Given its prevalence in apparel textile testing, it enables seamless comparison with similar materials. Moreover, it can fit for wet testing scenarios. The Martindale Test conducted using this equipment adheres to well-established Martindale Abrasion Test Standards, providing reliable and comparable results.

Disadvantages

The prescribed wool friction fabric in GB/T 3903.16—2008 often results in a relatively gentle rubbing action, leading to a less pronounced wear effect. The extended test duration, particularly for 51,200 frictions, which can span up to 18 hours, poses a logistical challenge. The preparatory steps are intricate, and thick specimens are cumbersome to install. Additionally, the single-use nature of the wool abrasive escalates consumable costs.

Applicability

The wool friction fabric’s limited wear-inducing capacity restricts its utility in accurately gauging the wear resistance of Flyknit uppers. However, substituting it with No. 600 water sandpaper, as per FZ/T 01121—2014, significantly amplifies the friction intensity and enhances the method’s suitability for medium-thickness Flyknit materials. When using the Martindale Abrasion Tester with the appropriate abrasive, it becomes a valuable tool for evaluating wear resistance in accordance with Martindale Abrasion Test Standards.

Taber Abrasion Resistance Method

Advantages

The rotating platform design, driven by the friction between the specimen and the grinding wheel, facilitates a large test area coverage. The operation is efficient, and the testing duration is relatively short.The extensive range of grinding wheel options, combined with adjustable parameters such as load and rotation speed, allows for rapid customization of test conditions, making it adaptable to various thicknesses. Its application in leather and synthetic leather testing further enhances its value for comparative analysis. The integrated dust suction mechanism, while noisy, aids in maintaining a clean testing environment.

Disadvantages

The sharp edges of the grinding wheel can prematurely damage the specimen periphery, necessitating the exclusion of these areas from assessment. The grinding wheel’s susceptibility to contamination requires regular and time-consuming cleaning procedures.

Applicability

The versatility in parameter selection and the relatively short test duration make the Taber method a preferred choice for a comprehensive assessment of Flyknit upper materials across different thicknesses.

Stroll Abrasion Resistance Method

Advantages

The sandpaper-based friction mechanism yields a pronounced wear effect. The adjustable load weight and straightforward operation protocol, coupled with a curved friction surface that emulates the in-use conditions of the upper material, are notable benefits.

Disadvantages

The limited friction area and suboptimal friction anisotropy, compounded by the absence of a real-time dust removal system and the generation of excessive debris, pose significant drawbacks. The inflation pressure constraints render it less suitable for thicker materials, as the variable friction area compromises result comparability.

Applicability

While suitable for thinner Flyknit uppers, its efficacy diminishes for thicker specimens due to the aforementioned limitations.

Analysis of Testing Results

The Martindale Test using the standard wool friction fabric as per GB/T 3903.16—2008 fails to induce significant wear in the Flyknit specimens even after 51,200 frictions. When we switched to using No. 600 water sandpaper, we noticed a significant increase in wear. Thin specimens exhibit substantial wear after 100 frictions, while thick specimens show moderate wear after 200 frictions. This method is most effective for medium-thickness materials, as it can be challenging to handle both thin and thick specimens. The Martindale Abrasion Tester demonstrates its value when set up correctly with the appropriate abrasive for various material thicknesses.

The Taber method elicits a discernible wear pattern in all specimens. Thin specimens endure severe wear after 300 frictions, while thick specimens display moderate wear. The method’s ability to accommodate various thicknesses, courtesy of its adaptable specimen fixation and parameter adjustment mechanisms, positions it as a reliable assessment tool.

The Stroll method, despite its simplicity, generates a relatively severe wear outcome, particularly for thin specimens. The limited friction area and the use of water sandpaper as the abrasive contribute to this effect. However, the challenges in accurately assessing textile materials, such as Flyknit uppers, due to the difficulty in observing yarn wear and the non-uniform friction results, render this method less than ideal.

Conclusion

In the pursuit of optimizing the wear resistance assessment of Flyknit upper materials, our investigations have unearthed several key insights.

Firstly, a consistent trend emerges across the three test methods: the abrasion resistance test of Flyknit uppers is directly proportional to their thickness.

Secondly, the Martindale Abrasion Tester, when augmented with No. 600 water sandpaper, emerges as a viable option for medium-thickness materials, while its original configuration with wool friction fabric proves inadequate.

Thirdly, the Taber method, with its flexible parameter tuning and efficient specimen handling, stands as a universal solution for evaluating the wear resistance of Flyknit uppers of all thicknesses.

Finally, the Stroll method, despite its initial promise, falls short in accurately assessing Flyknit materials due to its inherent limitations.

These findings serve as a compass for footwear manufacturers and researchers, guiding them in selecting the most appropriate testing methodology to ensure the durability and performance of Flyknit upper materials in the dynamic and demanding athletic footwear market.

By harnessing these insights, the industry can continue to innovate and refine Flyknit technology, delivering products that not only excel in comfort and style but also withstand the rigors of regular use.