This comprehensive blog explores the thermal comfort properties of various sports fabrics, including testing methods, performance analysis of different fiber fabrics, selection tips, and ways to improve thermal comfort. It also highlights the crucial role of machineries like Air Permeability Tester, CoolMax Cool Feeling Tester, and more in accurate fabric assessment. A must-read for textile industry professionals, fashion designers, and sports enthusiasts.

Introduction to Thermal Comfort in Sports Fabrics

In the realm of sports and leisure clothing, the thermal and moisture comfort of textiles is a critical factor. It directly impacts the wearer’s physical sensations and overall well-being. With the growing emphasis on health and comfort, the demand for textiles that offer excellent thermal and moisture management has surged. This blog delves into the intricate world of testing and understanding the thermal comfort properties of sports fabrics, with a particular focus on the machinery that enables accurate evaluations.

Testing Methods for Thermal Comfort Properties in Sports Fabrics

Fabric’s Basic Properties Testing

We start by looking at the fundamental characteristics. Referring to FZ/T 70010-2006 and GB/T 3820-1997, we measure the surface density and thickness of the fabric. The porosity, calculated using a specific formula, gives an indication of the fabric’s structure.

Air Permeability Testing

Air permeability is tested using an Automatic Air Permeability Tester in accordance with GB/T 5453-1997. Each fabric is tested 10 times at different positions, with the results averaged. A higher air permeability rate indicates better performance, making the fabric ideal for sports and leisurewear as it efficiently expels body-generated heat and moisture, enhancing comfort.

The ChiuVention AirFicient Air Permeability Tester, based on relevant standards like GB/T 5453-1997, is used to assess how well the fabric allows air to pass through. A higher air permeability rate, which this tester accurately measures, is desirable for sports fabrics as it helps in expelling heat and moisture. This tester is a smart device that allows for setting limits and checking the test status from a smartphone, thereby enhancing work efficiency. It is applicable to a wide range of textiles including technical fabrics, non-woven fabrics, and other breathable products, and is compliant with multiple testing standards such as ISO 9237, ISO 9073:15, JIS L1096 Item 8.26: Method C, BS 3424-16, BS 6F 100 3.1, NWSP 070.1 RO (15), GB/T 24218.15, etc.

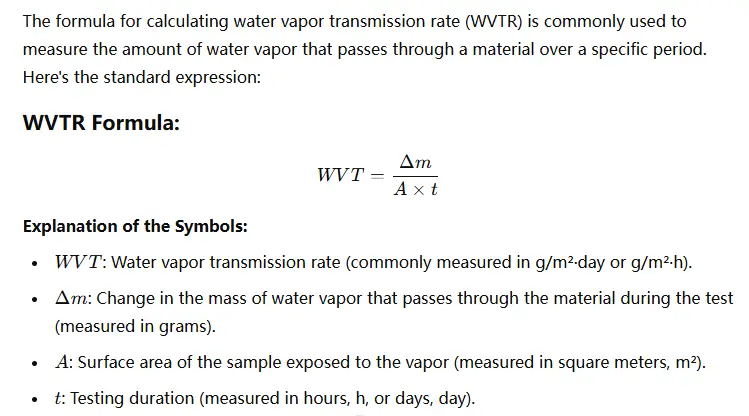

Moisture Vapor Permeability Testing

Moisture permeability is tested using a Moisture Permeability Tester following GB/T 12704.2-2009. Three samples from each fabric are tested, and the average value is calculated.

Based on GB/T 12704.2-2009, the water vapor transmission rate is determined. This property is crucial for keeping the wearer dry and comfortable during physical activities. The test measures how effectively the fabric allows moisture vapor to pass through, which is vital for maintaining the right microclimate next to the skin. A higher moisture permeability rate indicates better performance.

Thermal Insulation Properties Testing

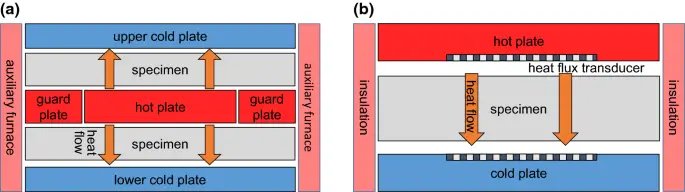

Thermal insulation is measured using a flat thermal insulation tester as per GB/T 1048-1989. Each fabric is tested three times, and the average value is calculated for insulation rate and thermal conductivity coefficient.

With reference to GB 1048-1989, the Guarded Hot Plate Apparatus is used to evaluate the thermal insulation rate and heat transfer coefficient of the fabric. Fabrics with better thermal insulation, as accurately measured by this apparatus, are suitable for colder conditions. It provides a reliable means of determining how well the fabric can retain heat and protect the wearer from cold.

Cool Feeling Performance Testing

The cool feeling property is evaluated using a Cool Feeling Tester following GB/T 35263-2017, which measures heat flux at five different positions on the fabric. The average value is used to calculate the cool feeling coefficient.

According to GB/T 35263-2017, the CoolMax Cool Feeling Tester measures the heat flux to determine the contact cool feeling coefficient. This is especially important for fabrics that come in direct contact with the skin. The tester can simulate real-life usage scenarios, with high-precision temperature sensors recording instantaneous temperature changes. The software then analyzes the data and generates Q-max values. It has adjustable parameters and yields very reliable results. IoT technology further enhances its functionality by allowing it to connect to smartphones and computers, and even link to ERP and LIMS systems, which greatly improves testing efficiency.

Thermal Resistance Testing

Thermal resistance is tested using a Thermal Resistance Tester based on GB/T 11048-2018, which employs a 35 cm × 35 cm sample area. Each fabric is tested three times, and the average value is recorded. A higher thermal resistance means better heat retention, which may or may not be suitable depending on the application. The testing process ensures that the fabric’s ability to resist heat transfer is accurately quantified.

Fabric Moisture Regain Testing

Moisture regain is measured following GB/T 9995-1997 using a ventilated oven to dry the samples and calculate moisture regain. This helps in understanding the fabric’s ability to absorb and retain moisture. It provides valuable insights into how the fabric will behave in different humidity conditions.

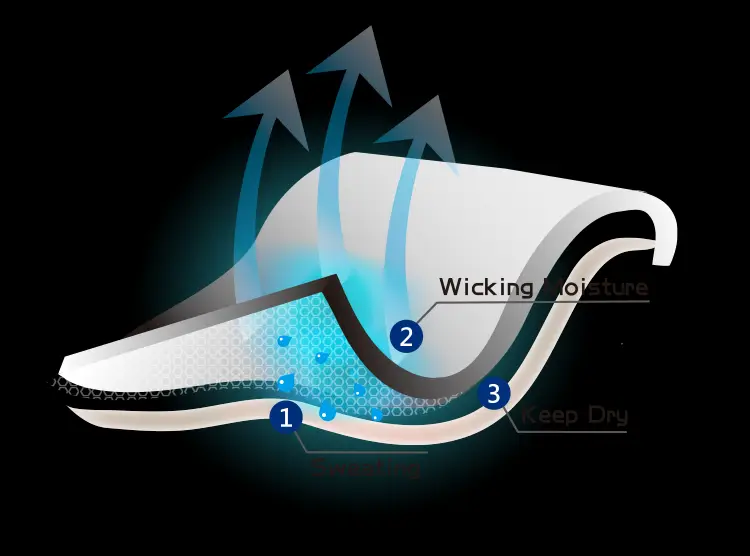

Moisture Wicking Testing

Moisture wicking properties are tested using an automatic absorption speed tester based on FZ/T 01071-2008, measuring liquid capillary height in both warp and weft directions. FZ/T 01071-2008 guides the testing of the liquid wicking height. Fabrics with good wicking properties can quickly move moisture away from the skin. This test is essential for assessing the fabric’s ability to manage liquid moisture and keep the wearer feeling dry.

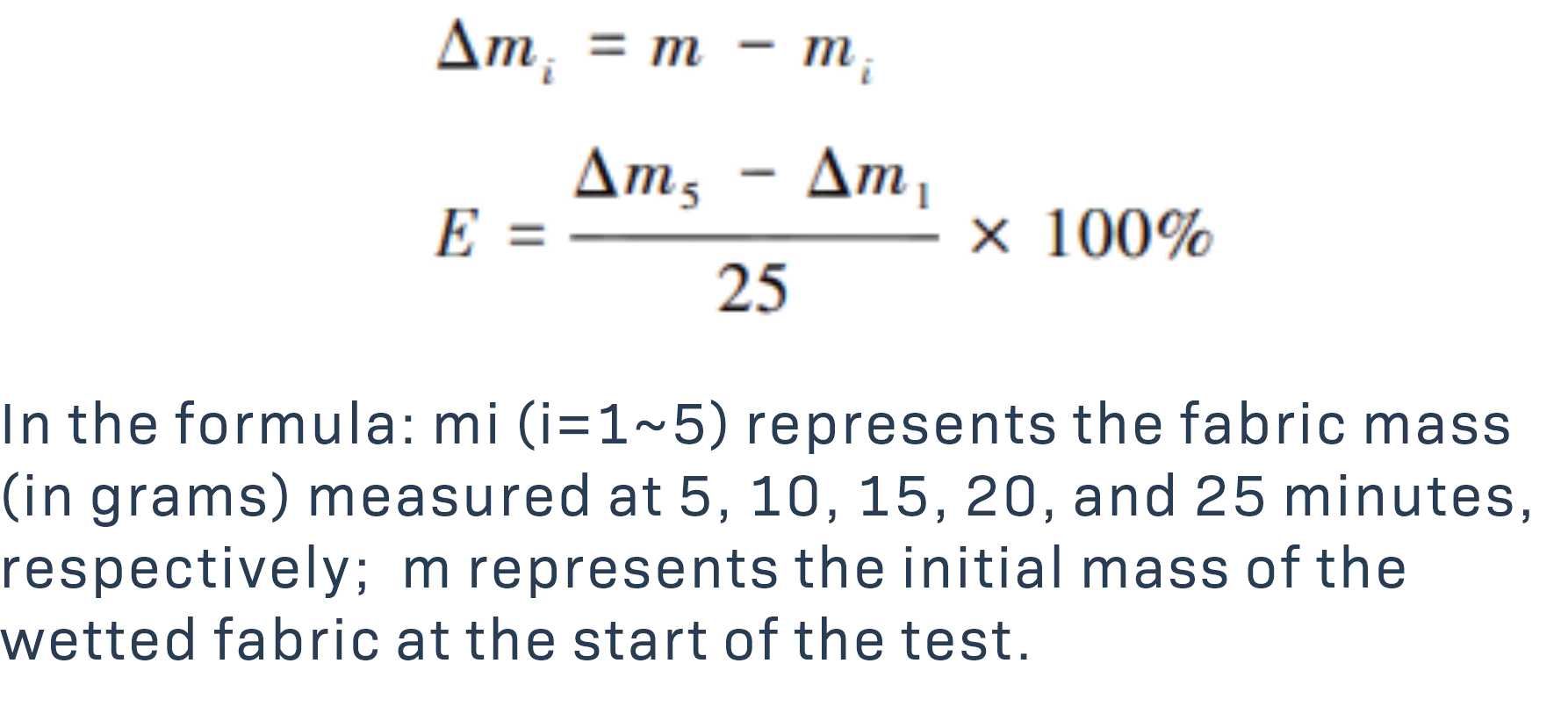

Moisture Evaporation Rate Testing

The moisture evaporation rate is tested as per GB/T 21655.1-2008, measuring fabric weight changes over intervals of 5, 10, 15, 20, 25, and 30 minutes. The average value is used to calculate evaporation rate.

As per GB/T 21655.1-2008, the Fabric Drying Rate Tester, which is compliant with AATCC 201, measures the rate at which moisture evaporates from the fabric. This tester has precise temperature and wind speed sensors, as well as precise water-dripping devices. It is mainly suitable for testing fast-drying fabric and accurately determines how quickly the fabric can get rid of moisture, which is crucial for maintaining comfort during physical activities.

Liquid Moisture Management Testing

The liquid moisture management tester, following GB/T 21655.2-2019, assesses the fabric’s overall moisture management capabilities. It measures parameters such as the wetting time (WT), maximum wetting radius (MWR), liquid water diffusion time (SS), and water absorption rate (AR) of the immersed surface (T) and permeated surface (B) of the fabric, and calculates the cumulative one-way transfer ability (0WTC) and overall moisture management ability (OMMC) to provide the liquid moisture management performance of the fabric (especially on the side close to the human skin). All the indices of the test are rated on a scale of 1 to 5.

Sweating Thermal Manikins Testing

These manikins simulate human sweating and measure parameters like wet resistance, moisture vapor permeability, and thermal resistance. They provide a comprehensive assessment of how the fabric will perform in a real-life sweating scenario, taking into account factors such as different body regions, postures, and movements.

Performance Analysis of Different Fiber Fabrics

Moisture-Absorbing and Sweat-Wicking Fiber Fabrics

Achieve the highest thermal and moisture comfort scores, outperforming polyester and cotton-blend fabrics due to their specialized grooves that enhance moisture transport.

Polyester and Moisture-Wicking Fabrics

Ideal for intense activities, these fabrics offer strong thermal and moisture transport capabilities, maintaining dryness.

Cotton Blends

While skin-friendly and absorbent, these fabrics have poor moisture-wicking capabilities, resulting in discomfort from sweat accumulation.

Nylon-Spandex Blends

Offer smooth, cool surfaces with high thermal conductivity, suitable for indoor fitness activities like yoga. The Air Permeability Tester and Temperature Humidity Chamber can accurately assess their performance in different environmental conditions.

Non-Treated Cotton Blends

Have strong heat transfer but relatively weak moisture transfer. Ideal for certain indoor fitness activities. The CoolMax Cool Feeling Tester can help in understanding their contact cool feeling properties, while the liquid moisture management tester reveals their limitations in handling moisture.

Selection of Thermally Comfortable Fabrics for Different Seasons

Summer Clothing Fabrics

Should be light, thin, and have good air permeability and moisture management. Customers preferred Fabrics like fine-count linen, silk, rayon, pure cotton, and polyester-cotton.

Winter Clothing Fabrics

Require high thermal resistance and low air permeability. People often choose thick, tight, and coated fabrics. The Guarded Hot Plate Apparatus is crucial in determining the thermal insulation properties of these fabrics, helping in the selection of materials that can effectively keep the wearer warm.

Methods to Improve the Thermal Comfort of Textiles

Enhancing the thermal and moisture comfort of textiles is a multifaceted process that involves material selection, fiber structure design, fabric construction, and finishing technologies. Below are some key methods and strategies:

Radiative Temperature-Regulating Textiles

By controlling the fabric’s transmittance of human infrared radiation, mid-infrared emissivity to the sky, and solar reflectance, these textiles manage the heat radiation exchange between the human body, clothing, and the environment to achieve cooling or insulation effects.

Phase-Change Temperature-Regulating Textiles

Using phase-change materials (PCMs) that absorb or release heat during temperature changes, these textiles maintain a comfortable skin temperature by regulating heat exchange.

Smart Responsive Textiles

Integrating stimuli-responsive polymers (SRPs), these fabrics can automatically adjust their structure in response to environmental temperature and humidity changes, enhancing heat exchange and improving thermal and moisture comfort.

Heat-Conducting Textiles

By utilizing materials with high thermal conductivity or altering the fiber structure, these textiles increase heat transfer efficiency, accelerating the dissipation of body heat to the environment for a cooling effect.

Energy Conversion Integrated Textiles

Incorporating micro-energy conversion devices, such as miniature fans or liquid cooling systems, these textiles enable personal thermal and moisture management.

Moisture Management Textiles

Developing fabrics that quickly absorb, transfer, and evaporate sweat reduces discomfort caused by sweat accumulation, improving the wearer’s thermal and moisture comfort.

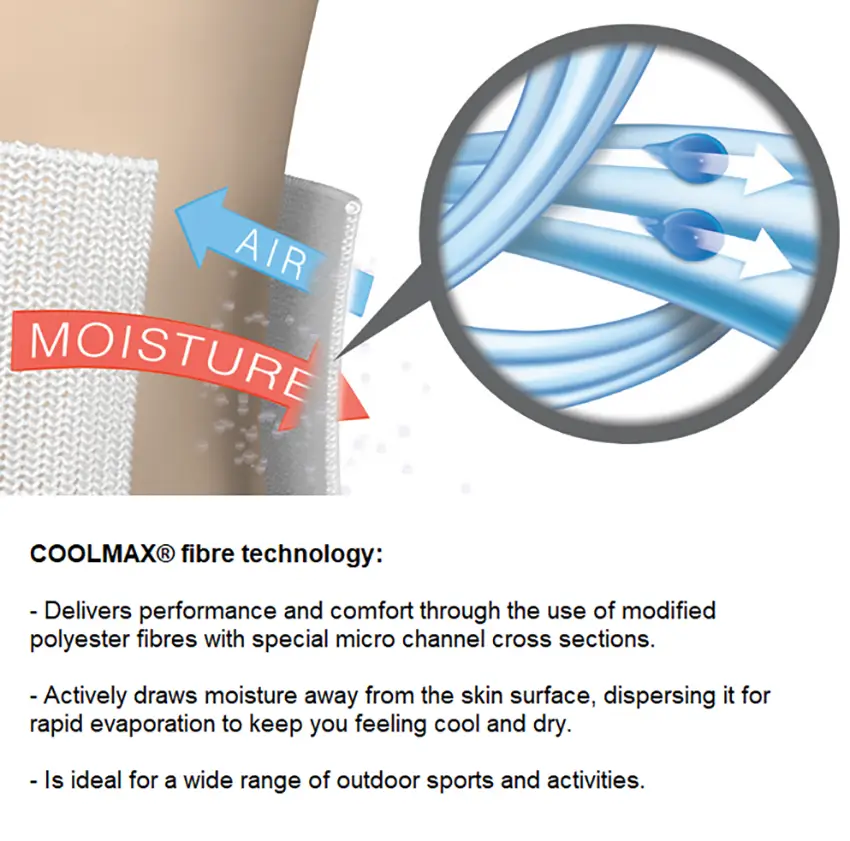

Fiber and Yarn Innovations

Using fibers with excellent moisture absorption properties, such as modified polyester fibers, and enhancing hydrophilicity through surface modifications to improve thermal and moisture comfort.

Fabric Structure Design

Optimizing the fabric’s weave structure to maintain appropriate porosity, store static air for insulation, and ensure efficient moisture transfer.

Finishing Technologies

Applying functional finishes such as moisture-wicking or sweat-regulating treatments, using chemical or physical methods to improve the fabric’s surface hydrophilicity or hydrophobicity, influencing sweat absorption, diffusion, and evaporation.

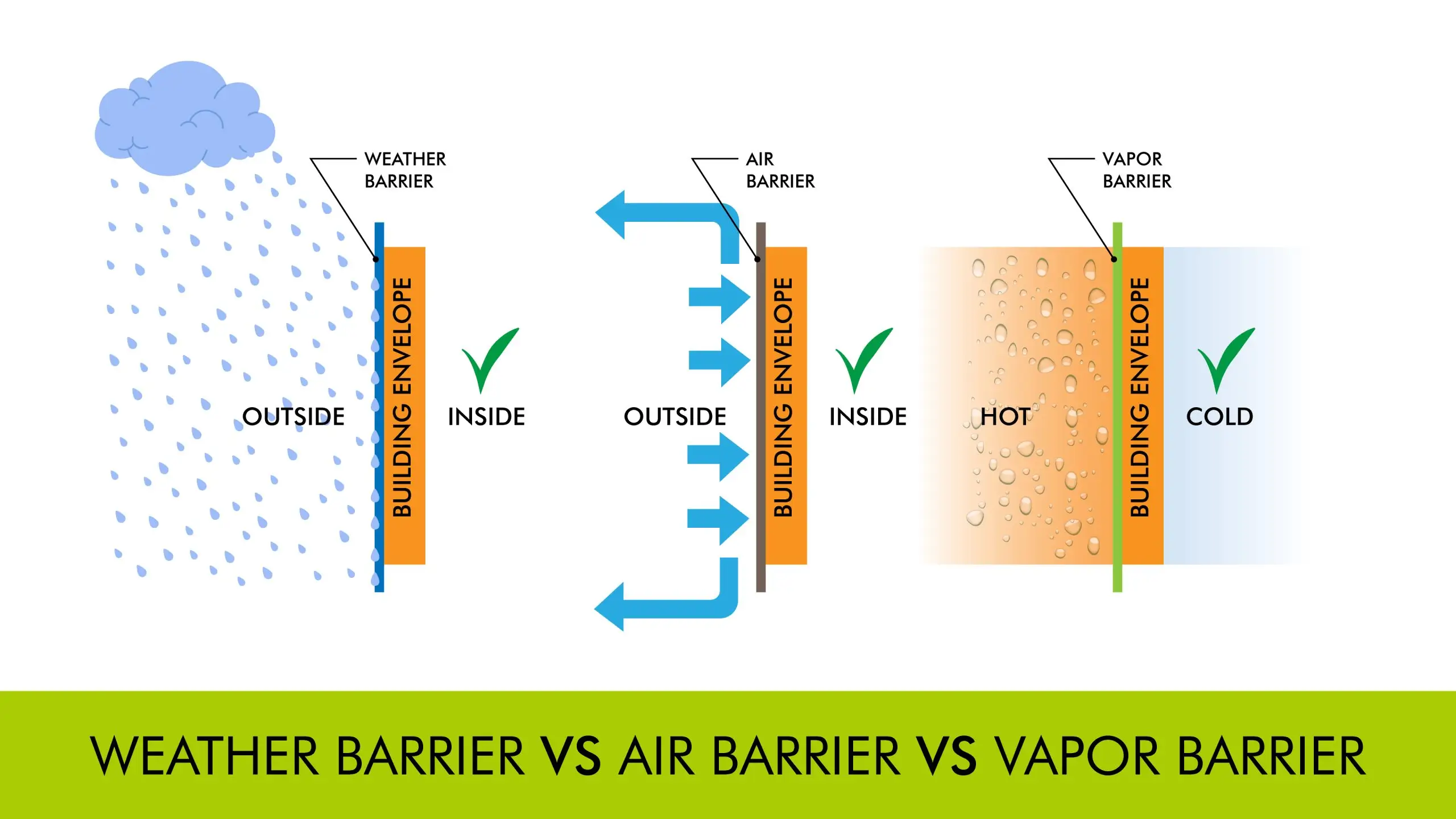

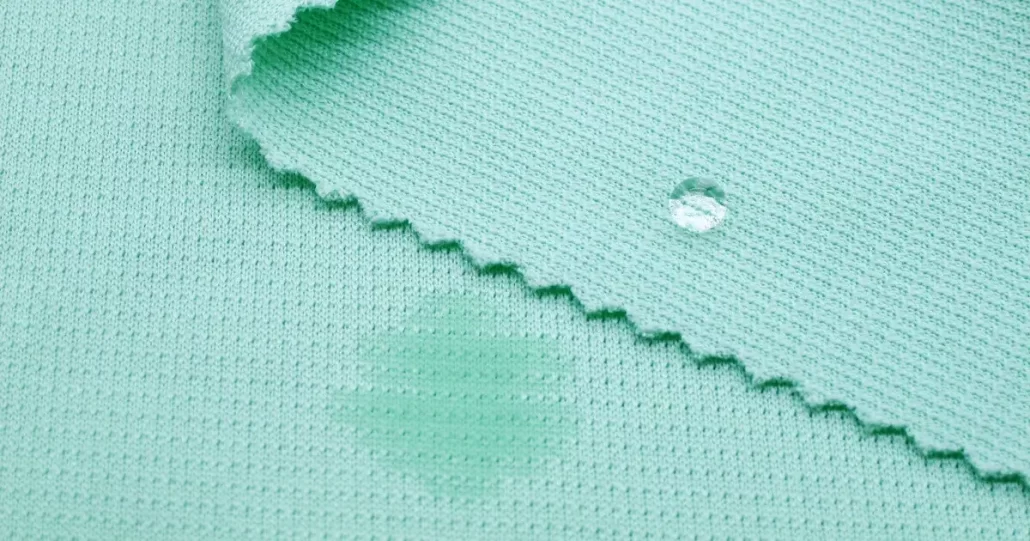

Development of Functional Fabrics

Creating specialized fabrics such as unidirectional moisture-wicking textiles and waterproof breathable membranes to cater to various environmental and usage demands.

By employing these methods, the thermal and moisture comfort of textiles can be significantly improved, meeting consumers’ demand for high-quality living while driving technological advancements and product innovations in the textile industry.

Related Testing Standards

We also explore important testing standards such as GB/T 39605-2020, GB/T 18398-2001, ASTM F2370, ASTM F1720, ASTM F1291, GB/T 33658-2017, and GB/T 43573-2023. These standards ensure consistency and reliability in fabric testing and evaluation. The machinery mentioned, such as the Air Permeability Tester, CoolMax Cool Feeling Tester, etc., can comply with these standards, providing accurate and comparable test results.

- GB/T 39605-2020: “Testing Methods for Clothing Moisture Resistance – Sweating Thermal Manikin Method”, applicable to the moisture resistance test of a whole set of clothing in an upright and stationary state, and can also be used as a reference for the separate moisture resistance test of the upper garment or the lower garment, as well as the moisture resistance test of clothing under different wind speeds, human postures, and movement speeds.

- GB/T 18398-2001: “Testing Methods for Clothing Thermal Resistance – Thermal Manikin Method”, applicable to testing the thermal resistance performance of clothing.

- ASTM F2370: This is an American Society for Testing and Materials standard, providing a standard test method for measuring the evaporative resistance of clothing using a sweating human model.

- ASTM F1720: Another for Testing and Materials standard, used for measuring the thermal insulation of sleeping bags using a heated human model.

- ASTM F1291: This is a replaced Testing and Materials standard, used for measuring the thermal insulation performance of clothing using a heated human model.

- GB/T 33658-2017: Chinese National Standard “Requirements and Evaluation Methods for Indoor Human Thermal Comfort Environment”, involving the requirements and evaluation of the thermal comfort performance of the indoor environment.

- GB/T 43573-2023: “Determination Methods for the Heat Dissipation Performance of Clothing – Sweating Thermal Manikin Method”, applicable to determining the heat dissipation performance of clothing.

Keywords: sports fabric thermal comfort, fabric thermal resistance, moisture vapor permeability test, breathable sports fabric, moisture management textile, hygroscopic fiber fabric, thermal insulation fabric, contact cool feeling fabric, fabric testing standards, textile heat dissipation, moisture-absorbing fabric, quick-drying sportswear fabric.

For more valuable insights on textile testing, we encourage you to subscribe to our website or reach out to us using the following contact information:

Email: sales@chivention.com

WhatsApp: +86 180 2511 4082