As we all know, a valuable product should be recognized by customers and be useful, safe, and secure. The success of each product is the overall result of successful operation in many areas, including design, production, marketing, transportation, and supply; only when these factors are perfectly handled can they be more valuable than competitors’ products. But now the quality is not enough! The growth of worldwide labs like textile testing labs in the USA or textile testing laboratories in India indicates that in the 21st century, where production tends to be international, an advantageous product should be a collection of high quality, high performance, and safety, namely:

Advantageous Products = Good Quality + Good Performance + Safety

Therefore, to comply with this trend, the establishment of a widely recognized quality control laboratory is necessary to enhance the competitiveness of products. Here are the 8 reasons we have listed for you to build a textile testing laboratory:

- Keep customers interested in you.

- Eliminate the buyer’s pressure on quality requirements.

- Maintain good quality of the product.

- Control the quality of daily production to avoid rework and scrap.

- Align consumer testing laboratories and factories with international standards (ISO 9002).

- Save daily commercial testing costs.

- Develop new products and open up new markets.

- Establish a good quality and market image for your company.

Start to Build a Lab from One to Five

- Step One: Make a timetable

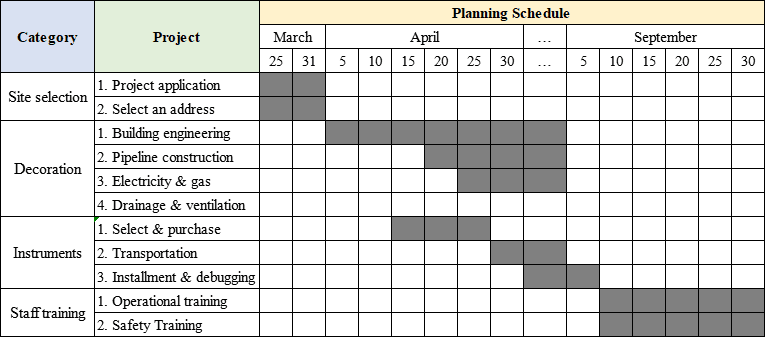

To establish a laboratory, you should consider the size of the laboratory, its decoration, the number of instruments, and the air conditioning system. Among them, the transportation of the instruments and the renovation of the laboratory take the longest time. Completing the above points may take 6 months. Make a schedule in advance so you can plan all the time effectively. For example:

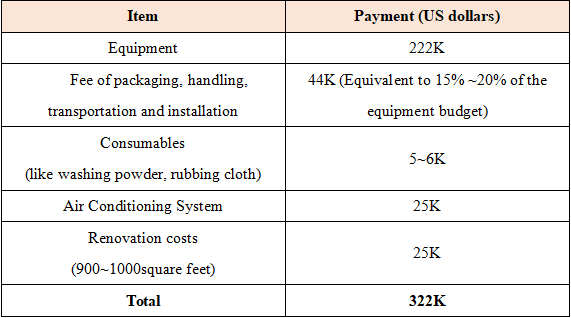

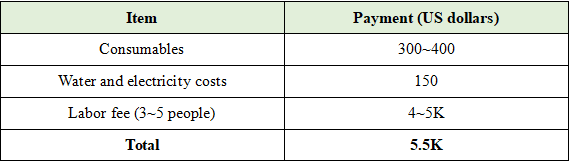

Step Two: Develop a budget plan

A. Initial investment

B. Monthly operating expenses

The above is just a rough budget. If there are other special expenses, such as the different equipment choices and experimental sites, the cost will be higher or lower. It is important to note that humidity and temperature control in the physical test room is essential and ChiuVention can provide you with more technical advice.

- Step Three: Design and decoration

The laboratory environment has strict standards. In terms of experience, it takes a day to conduct field visits and gain an in-depth understanding of the company’s quality requirements, which in turn determines the planning of the laboratory. This is a very effective way to avoid unnecessary troubles and mistakes.

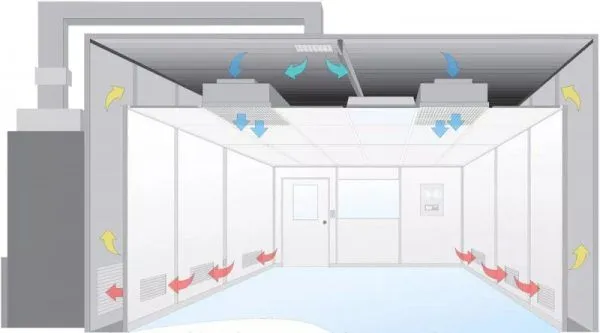

1) Air Conditioning System

Textile laboratories generally have air conditioning requirements, such as constant temperature and humidity, air purification, airflow, and exhaust. Moisture protection is required in humid climates. For early laboratories, a number of infrared lamps, small dehumidifiers, window air conditioners, and small freestanding air conditioners are required. Now modern internal quality control laboratory is best to use a central air conditioning system.

Air conditioning circulation system

2) Water, electricity & gas

Textile laboratories usually require both AC and DC power supplies, as well as single-phase and three-phase power outlets. Some need to have cooling water and various gas supplies, including vacuum and compressed air, protective gas and carrier gas, etc., as well as various pipes and equipment.

3) Others

The standards for the construction of textile laboratories are usually considered higher. The wall should be painted and coated; the ground should be made of terrazzo floor, plastic floor, or marble floor. The laboratory test bench, such as the sample processing room, can refer to the chemical test bench for the workbench; for the workbench for placing the instrument, the terrazzo countertop with reinforced concrete structure can be used. Similarly, special requirements like dust prevention and corrosion protection should be given sufficient attention and properly resolved.

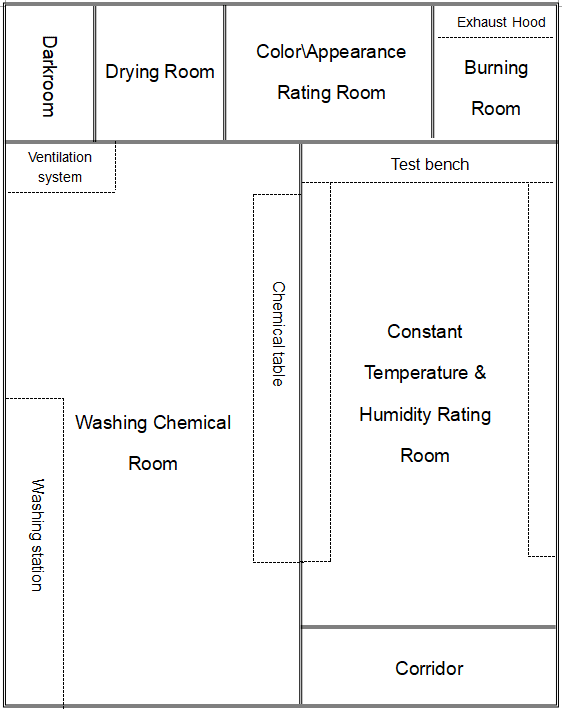

Typical laboratory layout design

- Step Four Select instruments and consumables

In general, if classified by textile, there are several types of quality control laboratory equipment:

Fabrics & garments testing equipment

Dyeing & Finishing & Coating & Printing equipment

For specific machines and corresponding performance, you can click on the instrument name above to learn more about textile lab testing procedures, then find suitable machines for your lab. Consumables in daily textile laboratories are mainly used in various tests, such as colorfastness tests, shrinkage tests, burst tests, and wear tests. There are also some benchtop protective films, wipes, weighing paper, test strips, chromatography paper, cellulose, fiberglass cartridges, and so on.

Some consumables from SDC.

- Step Five Installation, commissioning, calibration, and operation training

When we have completed the above steps, we will install, debug, and calibrate the equipment in the laboratory next. The corresponding installation and commissioning method needs to be requested from the instrument supplier.

We also need to conduct operations and maintenance training (basic operation of the equipment) for our staff, including color assessment and measurement theory and practice, chemical and glassware operations, safety education, and chemical calculations. The training helps to improve the staff’s expertise and operational skills and make the lab fully utilized. This usually takes 3~4 days. ChiuVention can provide you with training guidance in this regard, please feel free to ask our customer service.

If you finished the above 5 steps, a qualified textile quality control laboratory is complete. However, it is not enough to know how to build it. Next ChiuVention will take you deeper into the purpose of the textile laboratory and the corresponding equipment. Through learning, you can better understand the quality requirements of your products, and thus better establish a quality control lab.

What Tests are in the Textile Quality Control Laboratory?

Textile testing refers to the characteristics and properties of textiles obtained through inspection, measurement, and evaluation. This is usually necessary to determine if a product meets or complies with specified standards or other requirements. The textile testing laboratory is the place where many corresponding instruments are used to determine the potential value of textile products. In general, there are several types of fabric testing:

1) Physical test

Fabric physical testing is primarily a test of physical or natural mechanical properties. No chemicals including water will be used. Such tests include: breaking strength tests, tear strength tests, friction strength tests, and pilling tests.

2) Safety test

This type can be divided into three categories:

a. Chemical test

- Formaldehyde content test (JIS L1041)

- Heavy metal test (ASTM F963)

- Nitrogen-containing dyes

- Lead content (16 CFR 1303)

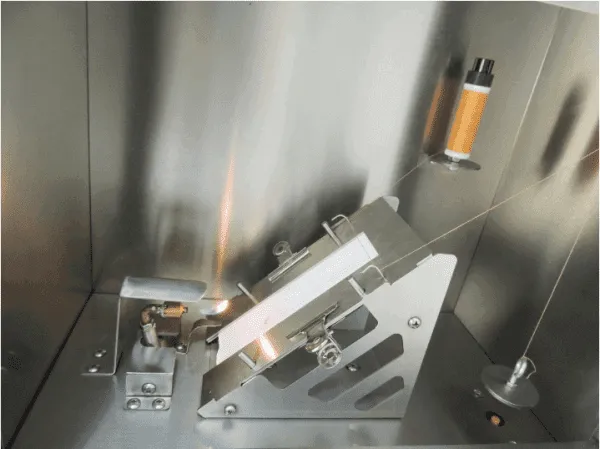

b. Burning test

- 16 CFR 1610

- EN71(part2)

- ASTM D 1234

- Method 5908 FTMS-191

- FTMS 5903

c. Mechanical test

- Small accessory test (16 CFR part 1501)

- Cusp test (16 CFR part 1500.48)

- Sharp edge test (16 CFR part 1500.49)

Generally speaking, (a) and (b) must be tested by a specialized laboratory because these tests require much more complicated equipment. Safety tests are often tested by the factory or buyer before shipping.

Listed below are some of the most widely used instruments in the world for your reference. If you want to know more detailed instrument information and textile testing methods, please click on the application at the end of the article to download:

- Main testing equipment (mechanical):

1. Textile Tensile Testing Machine

6. Auto Air Permeability Tester

All of these test instruments are specifically designed to test the potential for physical damage. Usually, a textile manufacturer will have several sets of test instruments and a set of accessory test instruments to test the entire process from design to transportation.

3) Color performance and physical appearance test

These tests are used to determine the resistance or amount of change in the color and appearance of the fiber to a variety of conditions. The fibers can be bleached or printed. Such tests include light fastness, wash fastness, shrinkage, etc.

4) Chemical test

In chemical testing of textiles, the use of chemicals is an important part (not including photoaging tests). Such tests include dissolution, application of test fibers and dyes, and the like.

5) Optical test

This type of test requires the use of a microscope or other magnification device. Such tests include wool fiber ratings, fiber tests, fiber defect tests, and more.

Look for Help from Professionals

In the textile testing industry, ChiuVention has a wealth of experience and expertise to solve your specific needs. We can provide you with comprehensive assistance to build an internationally recognized laboratory. Based on the above budget, ChiuVention can do more for you for these reasons:

- We are not only an experienced test instrument user, but also an expert in textile testing.

- We stand at the forefront of increasingly stringent textile testing requirements.

- We are constantly involved in the research of new test standards and methods.

- We provide customers with perfect pre-sales and after-sales service.

- We understand the correct needs of the end users and the market for the instrument.

- We are often designated by NIKE, M&S, GAP, and other companies to provide instruments for their suppliers.

The above is all the answers on the importance of textile testing and how to set up a textile quality control laboratory. If you have any questions, please feel free to contact our customer service or leave a comment below. We will be happy to answer your questions.