Fabric pilling and abrasion resistance are two key indicators of textile durability during use and wear. Pilling refers to the formation of small balls of entangled fibers on the fabric surface, while abrasion leads to loss of fibers or mass. Testing these properties is crucial for fabric development, quality control and ensuring functionality.

International standard test methods provide consistent, reliable, and reproducible evaluation across different materials and enable standardized performance claims. This article discusses the ISO standards for determining the pilling and abrasion properties of textiles.

What is the ISO Standard for Pilling Test?

The main ISO standard that specifies methods for measuring the pilling resistance of textile fabrics is ISO 12945. The standard, first published in 2000, defines multiple techniques that can select the appropriate test based on factors such as fabric construction, type of fibers, and intended end-use of the textiles.

The ISO 12945 standard specifies four primary methods:

-

Pilling box method

Researchers mount specimens flat or wrap them around rings inside a test box and then rub them against a defined abradant fabric for specific durations and stroke frequencies. We visually evaluate the formation of pills on the test specimens using standard area diagrams and 5-point grading severity scales at periodic intervals. You can vary parameters such as abradant fabric, stroke length, rubbing load, and mounting type.

-

Random tumble method

Enclose fabric specimens with loose abradant media of defined specification in a rotating drum. Intermittent tumbling action causes abrasion of test samples. Assessment involves comparing fabric appearance to sets of visual standards representing 5 degradation levels. One may also evaluate mass loss.

-

Continuous tumble method

Similar to previous technique but uses continuous tumbling action rather than intermittent agitation. Assessment methodology also follows the random tumble method specifications.

-

Modified ICI box method

Developed from the established ICI (Imperial Chemical Industries) Pill Box method. Involves fabric rubbing against sandpaper discs mounted on a pivot arm. Modifications aim to improve reproducibility and simulation of real-life friction. Pilling assessed from fabric appearance or mass loss data.

The methods range in severity levels with the pilling box being relatively mild while random tumbles produce more extreme pilling under harsh test conditions. Based on variation options, laboratories can fine tune procedures to match wear patterns in specific end-uses. The standard also defines sample sizes, environmental parameters, pre-treatments, and result reporting formats to ensure uniformity and repeatability across different test sites. We check compliance through round-robin inter-laboratory trials.

What is the ISO Standard for Abrasion Test?

ISO 12947 is the internationally recognized standard that lays down test methods for determining abrasion resistance of all forms and classes of textile fabrics. The initial versions were published in 1998 and revised in 2010. The techniques covered include:

-

Martindale abrasion test method

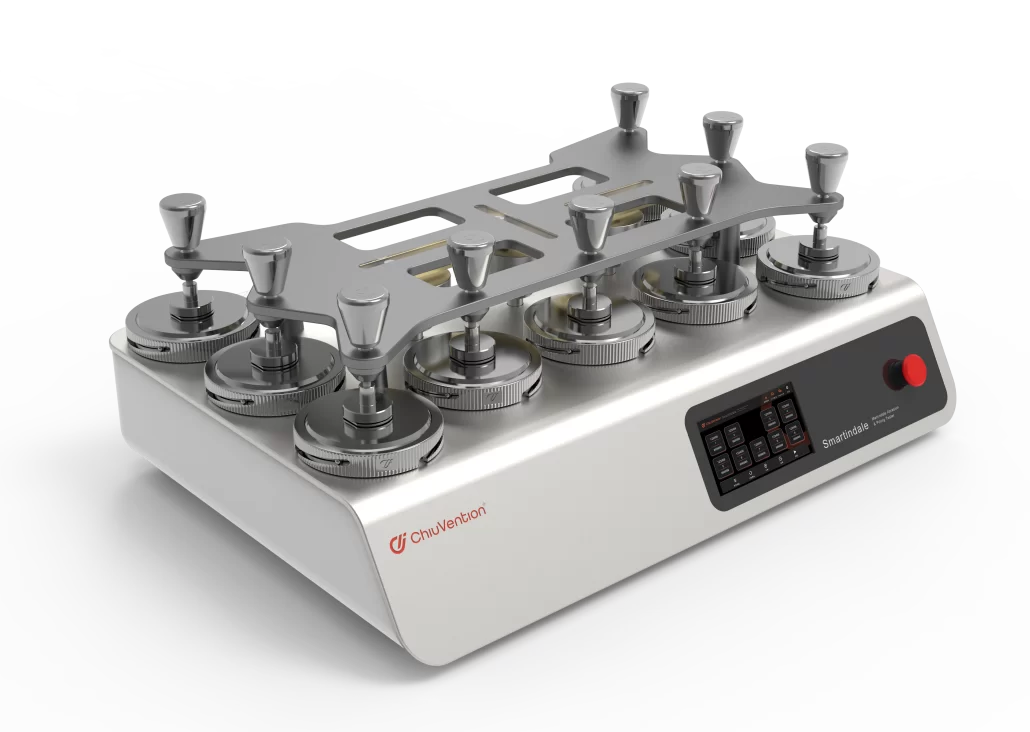

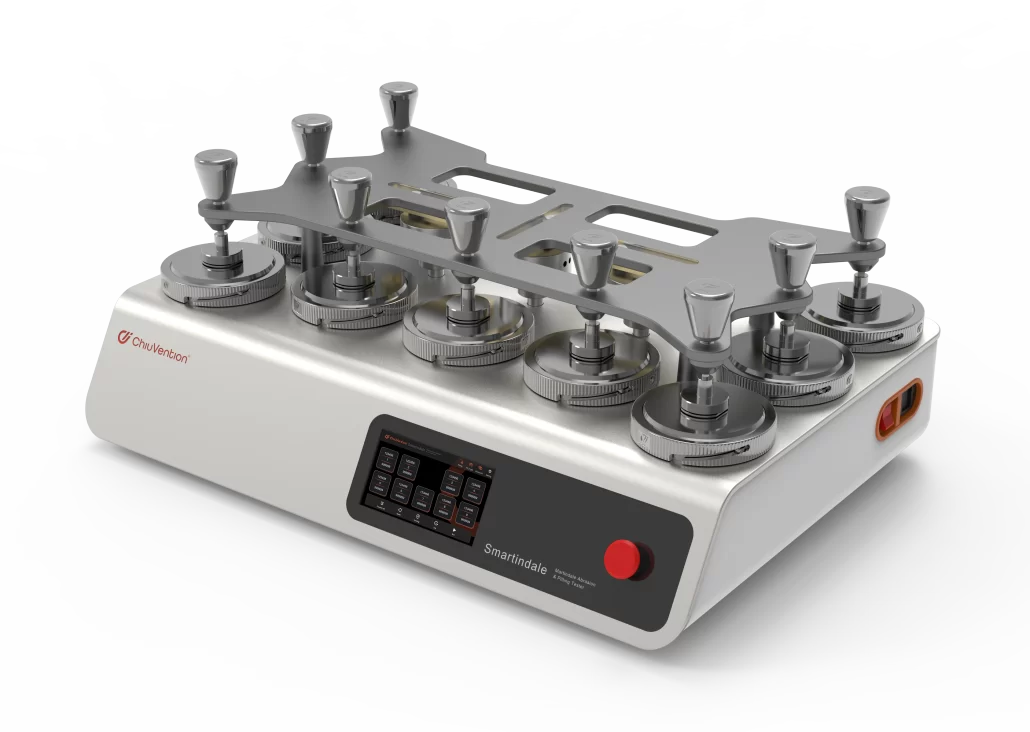

This method is also known as Martindale rub test, is a widely used method to determine the abrasion resistance of textiles and other materials. This pilling Matindale test is crucial for assessing the durability and wearability of fabrics, especially in applications like upholstery, clothing, and technical textiles. The operator securely mounts specimens flat on a holder plate and rubs a standardized wool abradant fabric linearly back and forth over the test surface under defined pressure. The rubbing motion and fabric path is arranged to simulate real wear. We assess the test endpoint by comparing it against visual references to determine appearance changes. Loss of mass may also be used to quantify abrasion resistance. Martindale fabric test is one of the most commonly used methods in the textile testing industry.

-

Random tumble method

Already described under the pilling standard. For abrasion assessment, mass loss of the fabric after tumbling action is used to indicate deterioration. Specimens may also be compared to standard photographs to grade wear level based on surface fuzzing or pitting.

-

Taber method

Circular test specimens are abraded using rotary action of two abrading wheels under controlled loads. The number of cycles taken to rupture fabric or induce measurable mass loss is evaluated. Testing can be done dry or wet.

As with pilling standards, the test method and variants can be chosen to simulate relevant wear modes for different textile products. Martindale technique sees wide adoption but is less discriminating for heavier fabrics intended for flooring or upholstery. The Taber method works better here. For apparel, mass loss may not correlate well with visible surface damage so visual grading is emphasized.

Test parameters like applied pressure, abrasive media, assessor qualification, environmental controls and reporting formats are clearly defined for reliability. But choice of technique, specimen size, end-point criteria and cycles can be optimized to align with product-specific demands.

How Does the ISO Pilling Test Compare to Other Methods?

While ISO 12945 standardizes the pilling resistance test methodology, some other well-known techniques include:

-

ICI Pill Box

One of the earliest methods developed by Imperial Chemical Industries. Test setup features single sandpaper wrapped disc rubbing against fabric mounted on 3D ring specimen holder. Provides relatively shorter, less severe test. Rating based on comparison with visual standards. Still widely used due to speed and discrimination ability.

-

Random Tumble Pill Box

Specified under ASTM D3512. Uses intermittent tumbling action in drum fitted with abrasives. Produces quick, reproducible test results. Considered excessively harsh and unrealistic for normal fabric wear.

-

Accelerator

Fabric coated rings are abraded inside an enclosure attached to base rotating at 70-100 rpm. Rapid test can discriminate between fabrics with marginal pilling variance. Does not simulate real-world pill formation accurately.

While other methods offer specific benefits, the ISO 12945 standard provides significant improvement through better simulation of wear modes and grading of pilling tendency rather than just pass/fail assessment. The range of techniques to choose from also facilitates matching relevant stress exposure. But cost and availability of required equipment is higher. Many laboratories still use complementary techniques like ICI box alongside ISO methods for more comprehensive analysis.

How Does the ISO Abrasion Test Compare to Other Methods?

Abrasion testing plays an integral role in assessing durability of textiles across industries. There exists a range of historical and modern test methodology tailored to simulate damage from rubbing and friction to model real-wear conditions a fabric may undergo during daily use or care. The ISO 12947 framework aims to harmonize these procedures for systematic analysis.

Key conventional abrasion analysis techniques include:

-

Wyzenbeek Method

Early technique using a mechanical device with abrading hammers in oscillating shuttle motion over a mounted fabric. The primary outcome measure is the number of strokes until fabric rupture. Assessment does not characterize wear appearance changes, only cycles to failure. Extensively used for apparel.

-

Stoll Quartermaster Fabric Abrasion Tester

Features rotating abrasive wheels under adjustable loads abrading horizontally stretched specimens. The military standard test specifies a wear rating based on cycles to specific endpoints defined for varieties of fabrics. Involves harsher, more rigorous testing parameters.

-

Accelerator Method

Adapted from the Taber method. A circular fabric test piece is eroded by rotating it inside a chamber with loose abrasives. The mass loss gets quantified but visual deterioration is not tracked.

-

Martindale Method

Circular fabric specimen rubbed against standard wool abradant fabric in Lissajous motion by Martindale test equipment. Assessment based on mass loss and appearance change is similar to ISO 12947 but utilizes a different visual grading scale commonly applied in Europe.

The ISO 12947 standard builds on the strong foundation of trusted abrasion test methods already established across different geographies and industries while promoting further standardization of procedures and calibration of visual assessments. Its emphasis on analyzing both mass loss and visually apparent surface changes leads to relatively comprehensive quantitative and qualitative assessment of wear resistance.

The flexibility provided via a range of variable test parameters also enables appropriate simulation of damage observed from different end-use conditions. The imaging-based digitization of surface deterioration enables more Resolution in judging incremental pilling.

However, many companies still extensively rely on singular techniques like Wyzenbeek that have been traditionally utilized to grade fabric abrasion resistance for specific applications. Most methods produce widely varying results so strategic combining of multiple test data yields more effective material evaluation. Over time, the reproducibility, digitization, and test flexibility of ISO 12947 is expected to achieve wider adoption as a unified global benchmark.

But the ISO standard development also provided the framework via which the best components of existing methodologies could be distilled, refined, and unified to improve overall test reliability and reproducibility across labs while reducing skill bias in assessments. The pictorial refs and digital imaging formalize the subjectivity of visual inspection. Newer parameters account for technological advances like high strength synthetics where traditional tools lacked Resolution. The ISO foundations thus foster incremental evolution of new testing landscapes.

How to test textiles for pilling and abrasion according to the ISO standard?

The ISO 12945-1 standard outlines the established methodology for determining the formation of pills and fuzz on textile fabrics. The test involves mounting fabric specimens on a rotating drum that abrades the surface of the material using a standard carding cloth for a specific number of rotations.

Specimen size and shape should adhere to ISO guidelines, with samples cut on the bias for knits. Securing the samples properly on the drum is key to preventing specimen movement and ensuring consistency across tests. Organizations like ASTM International provide standard abrasive carding cloths to utilize.

The drum rotates at the specified speed as the carding cloth rubs against the specimens under controlled temperature and humidity per ISO standard atmosphere conditions. Tests run for a defined number of rotations based on the material type – typically between 500 to 5000 rotations total.

Operators stop the test at set intervals to visually inspect and assign a rating from 5 (no pilling) to 1 (severe pilling), comparing against standard reference photographs. This qualitative grading combined with counting pill numbers determines the final pilling grade. Careful, consistent visual assessments and counting using adequate magnification and lighting are critical for reliable results. Get Martindale abrasion tester price below the picture.

How to analyze the results of ISO pilling and abrasion tests on textiles?

Analyzing ISO pilling and abrasion test results requires comparing the quantified pill counts and qualitative grade rankings to identify trends and assess overall resistance. The grader first ensures tests followed the methodology properly, with the appropriate rotational speeds, intervals, carding cloth, and atmosphere controls per ISO 12945-1.

The total pill count after all test cycles indicates the extent of pilling and loose fiber generation – higher is worse. Counts above a set customer or industry limit would be considered a failure. For qualitative comparison, the 1-5 visual grade at periodic inspection intervals shows degradation progression.

Compare resultant curves of the grade over test rotations for different textile materials and treatments. A steep curve downward signifies material that pills rapidly, while an initially low grade maintaining over rotations demonstrates good resistance.

The analyst can also derive more statistical metrics from the test data, like computing the average grade across inspections. Combining quantification with the qualitative grades enables benchmarking fabrics versus historical data, set quality criteria, or competitor materials to identify those prone to excessive pilling under abrasive wear.

Observing where pills and fuzz form on the fabric also reveals variations in cohesion across the material type and construction. Localized pilling may indicate twist imbalances in yarns or surface friction from raised fibers not fully concealed in the fabric structure.

Why choose the ISO pilling and abrasion standard for fabric testing?

The ISO 12945 framework for evaluating textile pilling and abrasion provides an internationally recognized, standardized methodology to assess and compare fabric durability during wear. Using these ISO standards allows manufacturers, suppliers, brands, and retailers to demonstrate objective evidence of material quality.

Given apparel and home textiles often endure repeated friction during cleaning and daily use, testing for resistance to pilling builds consumer trust in fabrics. Quantitatively counting pills and qualifying visual grading scales in ISO 12945 enable benchmarking versus specification limits or competitive offerings through reproducible laboratory test procedures.

By generating abrasion and pilling data backed by ISO standard testing methods, textile brands can substantiate product performance claims, differentiating offerings. For suppliers, following ISO protocols helps prove to buyers their fabrics withstand surface wear and avoid premature quality loss from pilling. That verified material durability supports higher pricing and preference in sourcing.

Globally adopting ISO standard Enums for pilling also facilitates communication between manufacturers, testing labs, retailers, and regulation bodies on recognized durability criteria. That provides consistency throughout the textile supply chain. Streamlining acceptance criteria also lowers compliance costs.

Moreover, the visual grading methodology in ISO 12945 improves standardization. Given subjective nature of perceiving pills, defining reference photographs eliminates variance – a grade 4 surface appearance means the same fuzzing and loose fiber levels across test labs. This inter-lab alignment in ratings enables external benchmarking.

How do ISO standards ensure fabric quality?

International Standards Organization (ISO) protocols and tests on textile performance provide quantifiable metrics that define quality benchmarks to ensure fabrics meet functionality needs and customer expectations.

For characteristics like dimensional stability, color fastness, durability and safety, ISO standards set reproducible test methodology along with pass/fail specifications. Fabric suppliers, manufacturers and retailers integrate these ISO testing regimes into quality assurance processes, certifying textiles comply with thresholds before reaching consumers. That screening validates quality criteria aligned to end-use, providing confidence in reliable performance.

Additionally, the standardized testing methodology of ISO protocols allows reliable comparisons between materials from different producers. That drives fair assessments, preferential sourcing and competitive differentiation for brands delivering textiles verified via ISO standards. Global alignment also facilitates trade with common criteria communicating what constitutes quality across regions. That interchangeability builds supply chain efficiency.

By undergoing ISO testing like abrasion resistance, tear strength, flame retardancy etc., manufacturers can benchmark inventories against fixed benchmarks indicative of suitability for particular applications, expediting product development. The visibility along the value chain given by ISO testing data aids decision making for upstream raw material suppliers as well. Standards propagation homogenizes information flow.

For retailers and brands, promoting ISO compliance provides credibility to advertising of features like wrinkle-resistance, durability, and safety; substantiated through internationally recognized testing bodies. That trust promotes customer loyalty. ISO certification also lowers risk and liability for clothing brands by upholding systematic safety and performance regulations across their supply network via documented compliance of standards.

Conclusion

As you can see, the ISO 12945 and ISO 12947 standards provide internationally recognized, standardized test methods for evaluating the pilling and abrasion resistance of textile fabrics. ISO 12945 defines multiple techniques from gentle pilling box rubs to harsh random tumble methods to simulate wear from end-use friction. Specimens are assessed by detailed visual grading of surface fuzz and loose fiber buildup, supplemented with pill counts for quantification. ISO 12947 outlines procedures leveraging rotating abrasive wheels or paper to rub fabric samples until rupture, signaling wear life cycles. Alongside quantifying mass loss, abrasion mechanisms in the standard also grade fabric appearance changes through formalized pictorial references.

These ISO standards aim to improve test reliability and alignment between labs by reducing subjective bias in visual assessments. The flexibility in methods and parameters also facilitates tailoring testing severity to actual in-use damage patterns. Globally adopting these protocols promotes unified performance criteria for quality control and supply chain transparency regarding durability claims.

However, many companies still rely on traditional abrasion analysis techniques deeply entrenched in specific industries or geographies. The ISO standards build on the strong foundations of proven legacy methods while pushing value-chain-wide standardization. Their emphasis on both quantifiable and visual ratings yields more holistic examination of wear resistance as well.

Over time, the versatility and reproducibility offered by these ISO standards is expected to achieve more universal application. But they provide an adaptive scaffold for continuously evolving new industry testing techniques without discarding established procedures. The image-based digitization of fabric degradation enables incremental improvements in the resolution and precision of pilling and abrasion analysis.

Overall, integrating ISO standard pilling and abrasion tests in quality assurance frameworks allows textile suppliers, manufacturers, and retailers to reliably demonstrate objective evidence of durable fabric performance to customers. This verifies quality, substantiates branding claims, and builds consumer trust.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: medium@chiuvention.com