Have you ever had your favorite shirt lose its color too soon? It’s a common problem affecting our clothes’ looks and manufacturers’ efforts to provide quality textiles. Color fading is more than just annoying; it’s a complex issue involving dyes, fibers, and washing. Let’s simplify everything about it in this guide.

The Basics of Color Fastness

Colorfastness is a material’s resistance to color change under various conditions. Beyond washing, it includes light, rubbing, and more – preserving color integrity.

Crucial in textile history, it ensures colors endure over time. From primitive dyeing to today, it’s vital for textile quality.

Why does Color Fastness Matter?

Quality Maintenance

Color fastness is crucial for maintaining textile quality, enhancing aesthetics, and showcasing craftsmanship.

Consumer Trust

It’s the linchpin for customer satisfaction, ensuring product brilliance lasts beyond purchase and building trust in the brand.

Brand Impact

Brands rely on color brilliance; failure in color fastness can lead to returns, complaints, and legal issues.

Benefits for Stakeholders

- Robust color fastness not only meets standards but also boosts the marketability of textiles.

- Retailers guide consumers with colorfastness knowledge for informed purchases.

- Understanding color fastness empowers consumers, transforming shopping into a thoughtful process.

Understanding Color Fastness to Washing

Factors Affecting Color Fastness in Textiles:

Colorfastness during washing is influenced by several crucial factors that determine color durability. Let’s explore these factors.

Dye Type and Quality

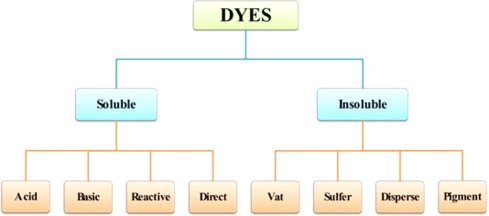

Dye Type

Reactive dyes chemically bond with fibers, ensuring excellent color fastness. Conversely, direct dyes may offer lower performance due to weaker fiber attachment.

Dye Quality

High-quality dyes resist fading and bleeding, preserving vibrant colors through multiple wash cycles. Investing in superior dye formulations significantly enhances color fastness.

Application Method

The technique of applying dye, such as pad-dyeing or exhaustion dyeing, affects color penetration and adherence to fibers. Proper application ensures even color distribution for improved color fastness.

Fiber Type and Construction

Natural vs. Synthetic Fibers

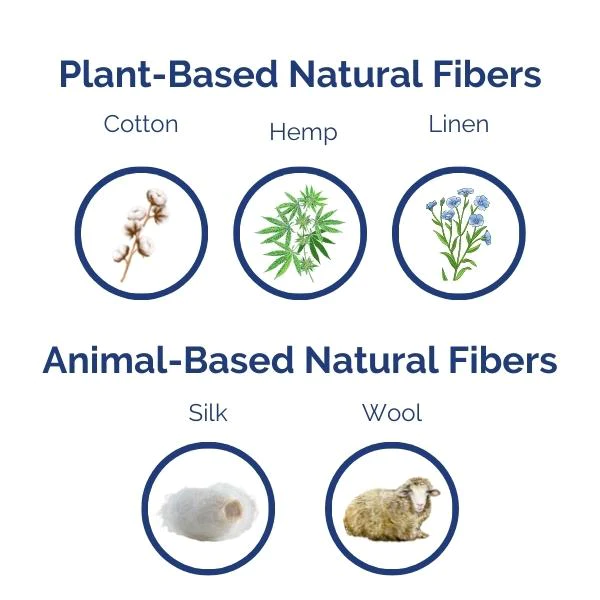

Natural Fibers

- Cotton: Known for absorbency, cotton generally exhibits good color fastness, with the choice of dye being crucial.

- Wool: Offers excellent color absorption but is sensitive to high temperatures and harsh chemicals.

- Silk: Delicate, requiring specialized care during washing for color vibrancy.

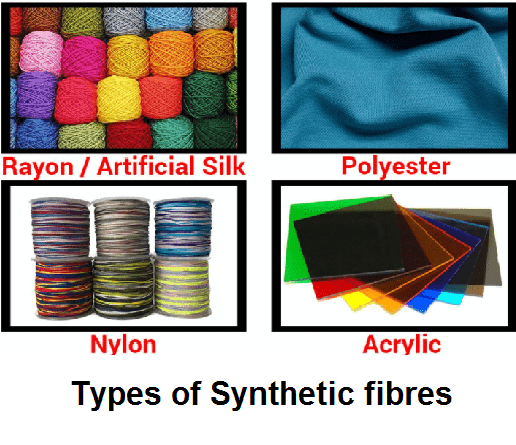

Synthetic Fibers

- Polyester: Resistant to fading, though prone to issues like pilling.

- Nylon: Generally good color fastness, requiring careful consideration of washing conditions.

- Acrylic: Known for good color fastness, with potential challenges related to pilling.

Weave and Construction

The fabric’s weave structure impacts color interaction. Tight weaves offer more protection against abrasion, reducing color loss. Understanding a fabric’s specific weave helps in predicting color fastness.

Finishing Treatments

Anti-Wrinkle Treatments

Balancing wrinkle resistance and color retention is crucial when using anti-wrinkle agents.

Stain Repellency Treatments

While protecting against spills, stain-repellent finishes can affect color fastness. Understanding compatibility with dyes is vital for maintaining color vibrancy.

Washing Conditions

Temperature

Washing temperature significantly influences color fastness. Higher temperatures accelerate dye migration and fading. Understanding optimal washing temperatures for different fabrics preserves color integrity.

Detergent Type

Harsh detergents expedite color loss. Choosing gentler detergents ensures better color retention over time.

Agitation Level and Wash Duration

Prolonged wash cycles and vigorous agitation increase mechanical wear, impacting color vibrancy.

Mechanisms of Color Loss

Staining of Adjacent Fabrics

In color fastness testing, it’s vital to grasp the intricacies of color loss. One key occurrence is the staining of nearby fabrics during washing.

During washing, agitation and water flow create an environment where loosely bound dye molecules detach. These liberated dye particles seek new surfaces to adhere to. If adjacent fabrics are present, unintended color transfer occurs.

Factors influencing staining

- Dye Affinity: Dyes with higher fiber affinity are more likely to stain adjacent fabrics.

- Water Temperature: Warmer water increases dye molecule mobility, heightening staining risk.

- Fabric Types: Different fabrics absorb migrating dyes at varying rates, affecting susceptibility.

- Washing Machine Conditions: The drum design and agitation level in washing machines play a significant role. Front-loading machines pose higher risks due to constant fabric immersion.

Preventive measures

- Separation: Isolate the test sample to simulate real-world scenarios, ensuring accurate results.

- Choosing Compatible Dyes: Opt for dyes with lower migration propensity based on textile use.

Dye Bleeding

Dye bleeding is when dyes leach out during washing, leading to unintended color spread. This is influenced by factors like uneven dyeing and poor dye fixation.

Defining Dye Bleeding

Dye bleeding happens when dye molecules fail to bind securely, washing out during laundering. It can lead to dyes migrating onto other fabrics.

Causes of Dye Bleeding

- Uneven Dyeing: Inconsistencies in dye application or distribution result in surplus dye prone to bleeding.

- Poor Dye Fixation: Inadequate fixation to fibers makes dyes wash out. Insufficient chemical bonding or heat setting contributes to poor fixation.

- Water Quality: Water mineral content and hardness impact dye fixation. Hard water interferes with dye-fiber bonding.

Preventing Dye Bleeding

- Proper Dyeing Techniques: Precise application and rinsing ensure uniform dye distribution.

- Fixation Processes: Thorough fixation through appropriate heat-setting methods and chemical treatments enhances dye stability.

Fading

Fading involves chemical and light-induced processes causing gradual color loss.

Types of Fading

- Chemical Fading: Induced by substances like bleach, chemical reactions alter or break down dye molecules.

- Light-Induced Fading: Sunlight, especially UV radiation, causes photodegradation, breaking down dye molecular structure.

Factors Influencing Fading

- Dye Stability: Dyes vary in resistance to chemical and light-induced fading.

- Fabric Composition: Natural fibers may be more prone to fading than synthetics.

- Exposure Conditions: Fabrics exposed to sunlight or harsh chemicals may experience accelerated fading.

Mitigating Fading Risks

- UV-Resistant Dyes: Opt for dyes formulated to resist UV degradation.

- Proper Care Instructions: Educate consumers on gentle washing methods and sunlight avoidance to preserve textile vibrancy.

Step-by-Step Guide to Conducting Color Fastness to Washing Test

Test Preparation

Equipment and Materials

Choose the Right Washing Machine

For accurate color fastness testing, opt for a front-loading washing machine. It provides gentler agitation, resembling real-world washing conditions. Ensure the machine complies with testing standards and calibrate it regularly for accuracy.

Use the Correct Detergent

Select a standard detergent without additives or bleach, adhering to industry norms. Detergent specifications, including pH levels, as variations can affect test outcomes.

Employ Multifiber Fabric

Use multifiber fabric as a testing substrate to simulate various textile materials. Ensure the fabric is consistent and free from color bleeding or dye transfer issues. Evaluate it against recognized standards for reliability.

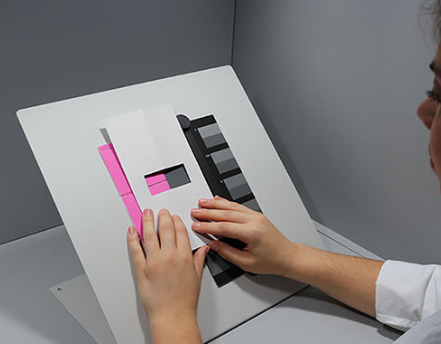

Include Grey Scales

Incorporate standardized grey scales with clearly defined color gradations as visual references for color change assessment. Regularly inspect and replace them to prevent inaccuracies in color evaluation.

Sample Preparation

Ensure Accurate Sample Preparation

Representative samples are crucial for accurate testing. Consider variations in dye distribution and label each sample meticulously with details like fiber content, dye type, and any specific treatments applied.

Follow Pre-Washing Procedures

In some cases, pre-washing is necessary to remove residual dyes or treatments. Follow standardized procedures, considering water temperature and detergent concentration. It ensures the color fastness test focuses solely on the textile’s inherent properties.

Test Procedure

Selecting a Testing Method

Introduction to Testing Standards

Colorfastness testing adheres to recognized standards like ISO 105-C06 and AATCC 61, ensuring reliability. These standards offer a systematic approach to uniform testing in the textile industry.

Choosing the Appropriate Method

Select the method based on textile use, material nature, and testing conditions. ISO 105-C06 assesses color fastness to washing, while AATCC 61 is for home laundering. Aligning the method with specific requirements enhances accuracy.

Washing Cycle Parameters

Temperature

Establish the correct washing temperature (e.g., 40°C or 60°C) to mimic real-world conditions. Consistent temperature settings maintain testing integrity.

Time

Define washing cycle duration based on textile characteristics and usage scenarios. Balance realism and efficiency for meaningful outcomes.

Detergent Concentration

Meticulously measure detergent concentration according to industry standards to ensure uniform testing conditions.

Water Volume

Maintain consistency by aligning water volume with testing standards. Accurate measurement is crucial to prevent variability.

Rinsing and Drying

Rinsing Procedures

Efficient rinsing removes residual detergents. Follow standardized procedures with specified water temperatures and durations for accurate test results.

Drying Methods

Standardized drying procedures, whether air-drying or machine-drying, influence the final color fastness assessment. Document conditions (temperature and duration) for consistency.

Evaluation

Assessing Color Change

Use Grey Scales

Evaluate color change meticulously using grey scales. Follow these steps for effective use:

Choose Appropriate Grey Scales: Select grey scales matching the testing standard, considering varying sensitivity levels.

Place Grey Scales Properly: Position grey scales next to the test sample, ensuring good illumination for accurate color comparison.

Compare Colors Systematically: Evaluate the test sample’s color against grey scale gradations, starting from the original color to gauge the extent of change.

Quantify Color Change: Utilize numerical or alphabetical markings on grey scales to quantify color change degree. Document this information thoroughly.

Record Observations: Note any nuances like uneven fading or specific areas with significant alterations.

Cross-Reference Findings: Compare results with industry standards to determine the acceptability of color change.

Assess Multifiber Fabric Staining

Visual Inspection

Conduct a detailed visual examination for visible stains or discoloration resulting from the test, providing initial insights.

Microscopic

Use microscopes for closer examination, especially with subtle or microscopic staining. Magnification helps detect even minor changes.

Photographic Documentation

Capture high-resolution post-testing photos for detailed analysis and comparison, serving as a visual record.

Comparative Assessment

Compare stained areas with an unwashed control sample to distinguish natural variations from washing-induced changes.

Quantify Staining

If possible, measure affected areas to add a quantitative dimension to your evaluation, aiding precise reporting.

Consider Testing Standards

Ensure your staining evaluation aligns with industry standards, as different standards may have specific criteria for acceptable staining levels.

Data Recording and Reporting

Importance of Documentation

Accurate documentation of test procedures, observations, and results is vital for traceability, reproducibility, and quality control. Detailed records allow others to replicate experiments accurately.

Test Procedures

Documenting procedures is essential for traceability and reproducibility, enabling precise replication by researchers, manufacturers, or quality control teams.

Quality Control

Detailed documentation is foundational for quality control, identifying any deviations from established protocols and ensuring the integrity of color fastness assessment.

Troubleshooting and Analysis

Thorough documentation aids in troubleshooting and analyzing unexpected results, providing a comprehensive basis for identifying issues in the testing process.

Observations

Identifying Patterns and Anomalies

Documenting observations allows for a nuanced understanding of color fastness behavior, revealing patterns or anomalies not immediately apparent during testing.

Continuous Improvement

Recorded observations contribute to continuous improvement by identifying areas for enhancement based on past testing, and refining procedures over time.

Comparison and Analysis

Detailed observations facilitate accurate result analysis when comparing samples or experiments, and identifying trends or variations through comprehensive documentation.

Results

Data Accuracy

Accurate recording of results ensures data integrity, with precision in noting color changes, staining levels, and other quantitative measures.

Decision-Making Support

Results documentation aids decision-making for manufacturers, designers, or quality assurance teams, enabling informed choices based on textile performance under specific washing conditions.

Regulatory Compliance

Meticulous result documentation is crucial for regulatory compliance, demonstrating adherence to color fastness standards in various industries.

Recommended Reporting Formats

Here are the comprehensive Test Report Components:

- Introduction: Provide a brief overview of testing objectives, methods, and materials used.

- Test Procedures: Detail specific steps, including equipment calibration, sample preparation, and testing conditions.

- Observations: Present detailed observations, including unexpected occurrences or nuances noted during testing.

- Results: Quantify results using standardized measurements, such as color change levels and staining assessments, using tables, graphs, or visual aids for clarity.

- Comparative Analysis: Include a section comparing results across different samples or testing scenarios, highlighting noteworthy variations.

- Discussion: Interpret results in the context of industry standards, offering insights into color fastness performance.

- Conclusion: Summarize key findings and their implications for tested textiles, discussing recommendations for improvement or further testing.

- Appendix: Include supplementary information like raw data, images, or additional notes enhancing understanding of the color fastness testing process.

Let’s take a brief example of the color fastness of the washing test procedure.

EU standard for colorfastness to washing: ISO 105-C06-2010, Textiles-Tests for color fastness-Part C06: Colour fastness to domestic and commercial laundering (Textiles-Tests for color fastness-Part C06: Colour fastness to domestic and commercial laundering).

Textiles and specified standardized lining fabric combination specimens are subjected to a washing, rinsing, and drying process in the test. The washing is carried out under suitable conditions of temperature, alkalinity, bleaching, and friction, while the friction effect is controlled by a low bath ratio and a certain number of stainless steel balls.

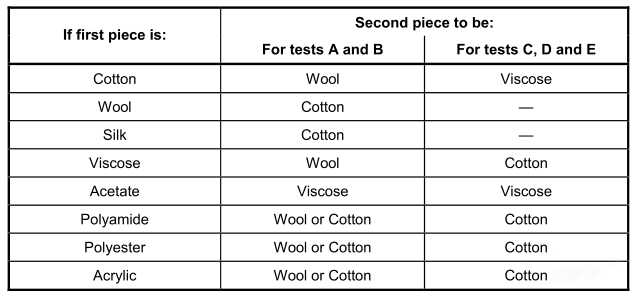

The specimen and lining size is (100±2)mm×(40±2)mm, and the lining fabric has single fiber lining, and multi-fiber lining (DW: low-temperature lining; TV: high-temperature lining).

Among them, the first piece of single-fiber lining is made of the same fibers as the test sample, the second piece of single-fiber lining is made of the materials as following table; specimens are blended or interwoven products, the first piece is made of main content of fibers, the second piece is made of less content of fibers.

Available Detergents.

ECE B phosphate-containing detergent (without fluorescent brightener)

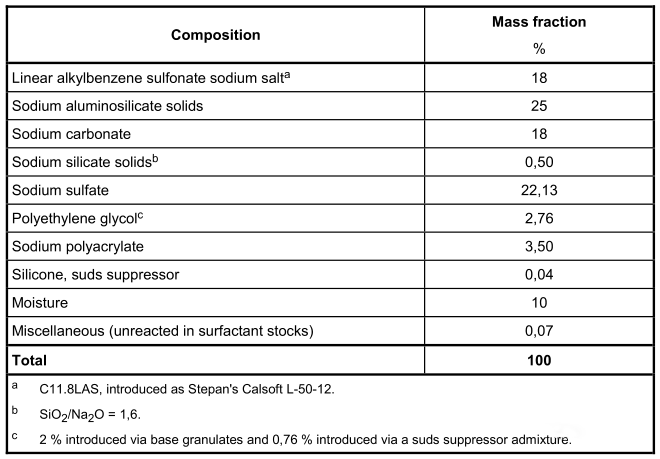

AATCC 1993 Standard Reference Detergent WOB, main ingredients are shown in the table below

Color changes and staining due to abrasive movement or dye resolution during a single test (S) are very close to the results produced by a single commercial or domestic wash.

The results of multiple tests (M) are close to the results of five commercial or domestic washes at 70°C or less.

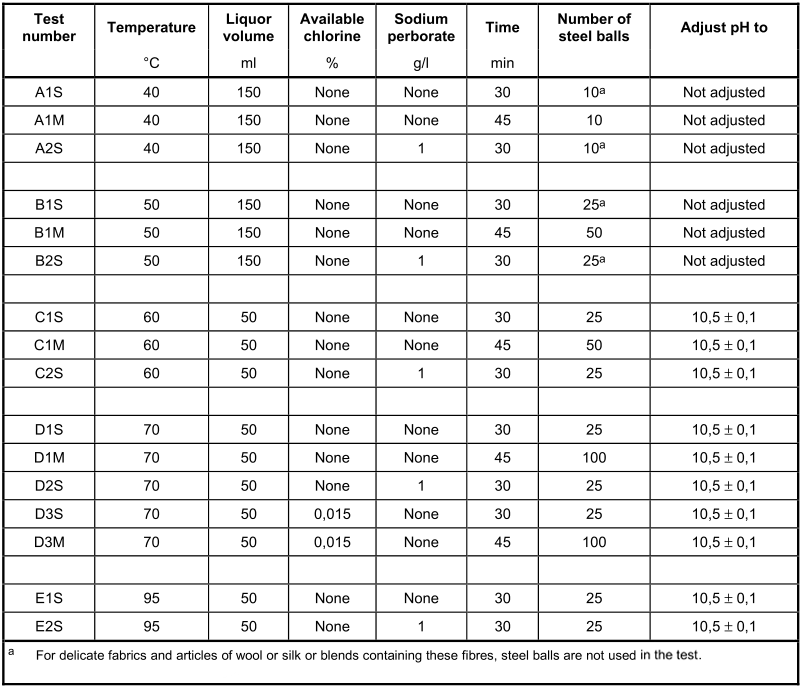

The test program is shown in the table below:

Table of Test Conditions

For all C, D, and E tests, adjust the pH with sodium carbonate, while A and B tests do not require pH adjustment.

Sodium perborate solution is ready to use, and the preheating temperature should not exceed 60°C. The D2S and E2S programs can only be preheated to 60°C first, and then the sample is placed in the washing process to warm up to the specified temperature within 10 min (the washing time is timed from the time the sample is placed in the sample).

The D3S and D3M test programs require the use of sodium hypochlorite to achieve the required effective chlorine content.

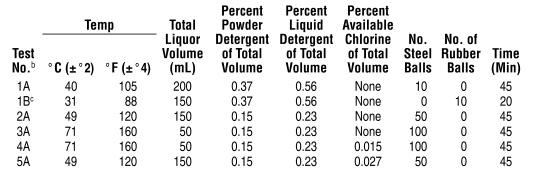

Next, I would like to introduce AATCC TM61-2013e(2020), its full name is AATCC TM61-2013e(2020) Test method for Colorfastness to Laundering: Accelerated.

AATCC TM61-2013e(2020) is an accelerated washing test method for colorfastness to laundering of textiles after frequent washing, whereby the fabric is subjected to the washing and rubbing action of five typical hand or home laundering loads, close to a single 45-minute test.

Interlining fabrics

①Multi-fiber appliqué containing acetate, cotton, nylon, silk, viscose, and wool;

② Multi-fiber appliqués containing acetate, cotton, nylon, polyester, acrylic, and wool.

Detergents

1993 AATCC Standard Reference Detergent (fluorescent brightener and phosphate free) or 2003 AATCC Standard Reference Liquid Detergent WOB (fluorescent brightener free)

1993 AATCC Standard Reference Detergent (with fluorescent brighteners and phosphates) or 2003 AATCC Standard Reference Liquid Detergent WOB (with fluorescent brighteners)

Specimen and lining size

50mm x 100mm for 1A, 50mm x 150mm for 1B, 2A, 3A, 4A, 5A;

1A, 1B, and 2A procedures apply multifiber lining, 3A applies multifiber lining or standard bleached cotton, 4A and 5A do not require lining.

Run program 1A with 75 x 125mm lever lock stainless steel tank, 2A, 3A, 4A, and 5A with 90 x 200mm lever lock stainless steel tank.

The washing program is shown in the table below

For The 4A and 5A procedures, add sodium hypochlorite solution to achieve the desired level of sodium hypochlorite:

For the 4A test program, first, prepare a 1500 ppm solution of effective chlorine and add the amount of sodium hypochlorite (g) = 159.4/concentration of sodium hypochlorite; for the 5A test program, add the amount of sodium hypochlorite (g) = 4.54/concentration of sodium hypochlorite.

Power up the machine and run the other test programs for 45 min and the 1B test program for 20 min.

The fading of the specimen fabrics and the staining level of the lining fabrics were evaluated with a gray card under a standard light source (D65).

Common Issues and Solutions in Color Fastness Testing

Improving Testing Consistency

Addressing Inconsistent Results

Inconsistent results often stem from equipment variations, impacting calibration, maintenance, or specifications. For instance, a malfunctioning washing machine can disrupt agitation levels, affecting textile color loss.

How to Solve Inconsistent Results?

- Standardize Procedures: A comprehensive, uniform protocol minimizes procedural variations, ensuring result stability.

- Calibrate Equipment: Adjusting machine settings to standardized conditions ensures reliability. Scheduled calibration routines uphold testing infrastructure precision.

- Integrate Control Samples: Known samples with predetermined color fastness properties enable continuous monitoring. Deviations from expected control results signal potential issues, prompting corrective measures.

Challenges in Interpreting Results

Interpreting color fastness results involves assessing color changes and potential staining. Challenges include subjectivity in perception, variation in grey scale interpretation, and complex rating systems.

Recommendations for Overcoming Challenges

- Training and Standardization: Comprehensive training standardizes evaluators’ perception and interpretation skills, addressing subjectivity and ensuring consistency.

- Establishing Reference Libraries: Creating libraries of color change examples encompass a spectrum of changes, allowing evaluators to compare samples with standardized references.

- Expert Consultation: Experts in color fastness testing bring years of experience and a nuanced understanding, providing clarity on ambiguous results.

Sample Selection

Accurate color fastness testing relies on representative samples reflecting real-world conditions. Selecting samples that align with the intended use ensures the relevance of test results.

Consideration of Diverse Materials

Textiles come in various materials, including natural fibers like cotton and wool, synthetic fibers like polyester and nylon, and blends. Ensuring a diverse representation of these materials in the sample pool is crucial for comprehensive testing.

Challenges and Mitigation Strategies

Collaboration with Industry Stakeholders

Establishing collaborative partnerships with manufacturers, suppliers, and industry stakeholders facilitates access to a diverse range of representative samples. This collaboration ensures a more comprehensive and accurate representation of textiles used in various applications.

Rigorous Documentation

Thorough documentation of sample characteristics, including fiber composition, production batch details, and intended use, helps maintain transparency. This documentation serves as a reference point for interpreting results and understanding the context of each sample.

Continuous Monitoring

Maintaining flexibility in the sample selection process and continually monitoring industry trends allow for adjustments based on emerging materials and technologies. This adaptability ensures that color fastness testing remains relevant in the face of evolving textile innovations.

Controlling Variables

Emphasizing Control of External Factors

Maintaining control over external variables is crucial for reproducible and reliable results.

Suggesting Methods for Minimizing Variability

Controlled Testing Environment

It may involve using environmental chambers or climate-controlled rooms where testing apparatus and samples are shielded from external influences.

Calibration of Equipment

Ensuring machines accurately replicate standardized conditions is essential for obtaining reliable results. Deviations in calibration can introduce variability, undermining the credibility of color fastness assessments.

Standardized Procedures

Adhering to standardized testing procedures can minimize variability. It includes precisely replicating each step of the testing process, from sample preparation to evaluation. Detailed and standardized protocols act as a safeguard against unintended deviations.

Monitoring and Documentation

Recording temperature and humidity levels throughout the testing process allows for post-analysis adjustments and provides valuable insights into the potential impact of external factors on results.

Quality Assurance Checks

Implementing routine quality assurance checks ensures the reliability of testing conditions. Regularly verifying the accuracy of equipment, monitoring environmental controls, and conducting dummy runs with known samples help identify and rectify any irregularities.

Comparison of Different Testing Methods

In color fastness testing, selecting the right methods is crucial for accurate results. Let’s explore key testing standards, compare parameters, and discuss cost and time considerations.

Popular Standards

ISO (International Organization for Standardization)

ISO 105-C06 is a global benchmark for colorfastness testing. It outlines procedures for assessing color fastness to washing, ensuring consistency across industries.

AATCC (American Association of Textile Chemists and Colorists)

AATCC 61 is a prominent standard for colorfastness to laundering, widely adopted in the North American textile industry.

Other Organizations

National and regional bodies, like the European Union, may set guidelines for color fastness testing to meet regulatory requirements.

Test Methods

- ISO 105-C06: Assesses color fastness to washing using standardized conditions.

- AATCC 61: Evaluates colorfastness to laundering through controlled washing with specific detergent.

- GB/T 3921.3: Chinese standard for color fastness to washing, providing specific procedures for assessing color retention.

Key Parameters Comparison

Evaluation Methods

Grey Scales

- Advantages: Quick visual assessment, widely accepted.

- Limitations: Subjective, less precision compared to instruments.

Spectrophotometry

- Advantages: Precise, objective measurement for accurate results.

- Limitations: Requires specialized equipment, influenced by environmental factors.

Applicability to Textile Types

Natural Fibers

- Greyscales: Effective due to natural fibers’ straightforward color properties.

- Spectrophotometry: Provides detailed quantitative data for research.

Synthetic Fibers

- Grey scales: May miss subtle changes; spectrophotometry is more reliable.

- Specific standards: Address unique challenges of synthetic fibers.

Cost and Time Considerations

Cost

- Grey Scales: Minimal cost for visual assessments and standard color charts.

- Spectrophotometry: Higher initial investment but cost-effective long-term due to increased precision.

Time

- Grey Scales: Quick and straightforward for rapid assessments.

- Spectrophotometry: Longer processing time due to equipment calibration and data analysis.

Table for Quick Comparison

| Criteria | Grey Scales | Spectrophotometry |

| Advantages | Simple visual assessment | Precise and objective measurement |

| Limitations | Subjective interpretation | Requires specialized equipment |

| Applicability to Textile Types | Effective for natural fibers | More reliable for synthetic fibers |

| Cost | Minimal | Higher initial investment, cost-effective long-term |

| Time | Quick | Longer processing time |

Impact of Washing Conditions on Color Fastness

Temperature

Understanding the impact of washing temperature on fiber types is crucial for vibrant and enduring colors. Elevated temperatures pose a risk of accelerated dye migration and fading.

Cotton at High Temperatures

- Cotton tolerates higher washing temperatures well but prolonged exposure can cause color fading.

- Example: Washing above 40°C gradually diminishes colors.

Wool’s Susceptibility

- Wool fibers are heat-sensitive; even lower temperatures can result in noticeable color changes.

- Example: Washing above 30°C may alter wool colors.

Silk’s Delicate Balance

- Delicate silk demands care; higher temperatures can lead to color bleeding.

- Example: Washing above 25°C compromises silk’s color integrity.

Polyester’s Tolerance

- Synthetic polyester endures higher temperatures, up to 60°C, without substantial color loss.

- Example: Polyester fabrics maintain color at 60°C.

Detergent Type: pH and Bleaching Considerations

Detergents, often unsung heroes, play a vital role in color fastness. pH levels and bleaching agents significantly impact color integrity.

pH Levels

- Cotton tolerates a range of pH levels (7-9) without color consequences.

- Example: Slightly alkaline detergents ensure effective cleaning without compromising cotton colors.

Wool’s pH Sensitivity

- Wool, pH-sensitive, requires neutral to slightly acidic detergents to prevent color changes.

- Example: Acidic detergents (pH 5-7) maintain wool colors.

The Bleaching Challenge

- Harsh bleaching agents accelerate color loss, especially in natural fibers.

- Example: Chlorine-based bleach in detergents fades cotton over time.

Gentle Alternatives

- Opt for bleach-free detergents for both natural and synthetic fibers.

- Example: Oxygen bleach alternatives maintain vibrant hues.

Washing Time and Agitation: Balancing Cleanliness and Color Preservation

Understanding the balance between cleanliness and color preservation involves optimizing wash times and agitation based on textile characteristics. Prolonged wash times and vigorous agitation impact textiles:

Prolonged Wash Cycles

- Extended wash times increase mechanical wear, affecting color retention in cotton.

- Example: Prolonged washing gradually diminishes cotton color vibrancy.

Wool’s Sensitivity to Agitation

- Delicate wool fibers are susceptible to damage from strong agitation.

- Example: Intense agitation causes wool garments to lose color.

Optimal Washing Parameters

- Synthetic fibers tolerate longer wash times and stronger agitation.

- Example: Polyester endures extended wash cycles without color impact.

Water Quality

Understanding water quality nuances and making adjustments ensures resilient color fastness against this hidden influencer. Water hardness and mineral content impact color integrity:

Hard Water’s Effect

- Calcium and magnesium in hard water contribute to color fading in textiles.

- Example: Cotton in hard water may experience diminished color vibrancy.

Adjustments Based on Water Quality

- Softening techniques counteract hard water effects.

- Example: Adding a water softener maintains color integrity.

Interpreting Color Fastness Test Results for Textiles

Decoding Grey Scale Ratings

Colorfastness testing utilizes numerical and alphabetical grey scales to evaluate color changes and staining on textiles.

Numerical Grey Scales

- The Grey Scale for Color Change features numbered patches, each representing a degree of color change.

- Higher numbers signify more significant alterations.

Alphabetical Grey Scales

- The Blue Wool Scale uses letters (A to F) to denote staining levels.

- A represents minimal staining, while F indicates severe staining.

Establishing Acceptable Limits

Defining acceptable color fastness levels is crucial, considering:

The Intended Use of the Textile

- Align acceptable color fastness levels with the textile’s purpose.

- Everyday wear may tolerate slight changes, while delicate garments demand higher standards.

Industry Standards and Consumer Expectations

- Adhere to ISO and AATCC guidelines for industry standards.

- Meeting or surpassing these standards ensures alignment with consumer expectations.

Implementing Corrective Actions

- Adjusting Dye Selection and Application: Identify problematic dyes and adjust selection or application methods for better adherence.

- Modifying Fiber Blends or Finishing: If issues persist, consider altering fiber blends or applying different finishing treatments.

- Optimizing Washing Instructions: Educate consumers on optimal washing practices to mitigate color loss.

Addressing Inter-laboratory Variability

Ensuring consistent results involves recognizing and minimizing variability:

Factors Contributing to Variability

- Discrepancies in equipment calibration, testing procedures, and sample preparation impact results.

Strategies for Minimizing Variability

- Implement standardized protocols, regular equipment calibration, and use control samples.

- Collaboration between testing laboratories enhances result consistency.

Innovations in Color Fastness Testing Technology

Precision Through Instrumental Methods

Revolutionizing Color Measurement

In color fastness testing, instrumental methods, particularly spectrophotometry, have transformed our ability to precisely measure and quantify color attributes. Unlike subjective visual assessments, spectrophotometry employs specialized instruments to measure light intensity at various wavelengths.

Objective Results Over Visual Assessment

Spectrophotometry surpasses traditional visual assessments by eliminating subjectivity, ensuring objective and reproducible outcomes. It enables accurate measurement of color attributes like hue, saturation, and brightness, facilitating quantitative analysis of dye loss. Manufacturers can rely on these results for consistent color across production batches.

Advanced Imaging Techniques

Beyond spectrophotometry, advanced imaging techniques provide powerful insights into color fastness. High-resolution imaging reveals intricate details of color change patterns and staining not visible to the naked eye, enhancing understanding of textile performance under various washing conditions.

Accelerated Testing for Efficiency

Condensing Real-World Wear Simulation

Traditional color fastness testing, involving multiple washing cycles, can be time-consuming. Accelerated testing methods simulate these cycles in a condensed timeframe, offering rapid insights into a material’s color retention capabilities. This innovation is particularly valuable for manufacturers aiming for efficient quality control.

Balancing Speed and Accuracy

Accelerated testing methods reduce time and cost but may not perfectly replicate real-world wear and tear. Striking a balance between efficiency and simulation accuracy is crucial for manufacturers to ensure reliable predictions of color fastness.

Sustainable Practices for Environmental Responsibility

Aligning with Sustainability

As the industry emphasizes sustainability, color fastness testing methods have evolved to embrace eco-friendly practices. Sustainable testing aims to minimize environmental impact without compromising result accuracy.

Examples of Sustainable Testing

Incorporating biodegradable detergents, water recycling systems, and energy-efficient equipment characterizes sustainable color fastness testing. Researchers explore innovative dyeing processes to reduce the ecological footprint. Adopting these practices enables the textile industry to contribute to environmental conservation while maintaining fabric longevity and vibrancy.

Influence of Different Fiber Types on Color Fastness

Natural Fibers

Cotton

Cotton, a textile staple, maintains good color with the right dyes. Opt for reactive dyes to chemically bond and enhance color retention. Use antimicrobial finishes to address moisture absorption issues.

Wool

Luxurious wool requires gentle care due to sensitivity to heat and chemicals. Preserve color with cold water and mild detergents. Recommend dry cleaning for delicate wool items.

Silk

Elegant silk demands careful washing. Hand Wash in cold water with mild detergents to prevent color bleeding. Air-dry instead of tumble-drying for prolonged color fastness.

Synthetic Fibers

Polyester

Polyester shows commendable color fastness but may pill. Turn garments inside out before washing to minimize abrasion. Use fabric softeners moderately to reduce static and friction.

Nylon

Nylon, strong and elastic, maintains good color fastness. Wash in cool water with mild detergents to prevent color degradation. Avoid excessive heat during ironing.

Acrylic

Acrylic fibers have good color fastness but may pill. Use gentle washing methods, turning garments inside out and avoiding rough textures. Discourage high-speed spins in washing machines.

Blended Fabrics

Blended fabrics present unique challenges. Tailor testing to individual fiber properties. Adopt a comprehensive approach considering the characteristics of both natural and synthetic components.

Regulations and Standards for Color Fastness Testing

The Power of Standardization

Standardization is the backbone of reliable color fastness testing in textiles, ensuring uniform results and supporting global trade.

- Standardized methods create consistency, minimizing variations in procedures and equipment.

- Consistency guarantees comparable results across diverse laboratories, instilling confidence in assessments.

Enhancing Global Trade

Harmonized standards simplify international commerce, offering a universal language for assessing color fastness.

- Manufacturers in global markets benefit by meeting diverse consumer and regulatory expectations.

- Adhering to standards boosts product quality, consumer confidence, and market competitiveness.

Practical Gains for Manufacturers and Consumers

For Manufacturers

- Standardized testing enhances product quality, builds consumer confidence, and streamlines compliance.

- Facilitates adherence to industry regulations, easing product development processes.

For Consumers

- Consistent testing ensures products meet quality benchmarks.

- Enables informed purchases based on universally understood color fastness ratings.

Accreditation Assurance

Accreditation bodies ensure testing laboratories adhere to standards.

- Accredited labs inspire trust, fostering industry-wide confidence in test results.

Understanding key regulatory bodies is essential for navigating color fastness testing standards.

- International Organization for Standardization (ISO): A global leader providing guidelines like ISO 105-C06.

- American Association of Textile Chemists and Colorists (AATCC): Significant contributor with AATCC 61 focusing on color fastness to washing.

- National and Regional Bodies: (e.g., European Union) Set region-specific standards ensuring compliance.

Scope and Influence

Exploring the reach of organizations offers insight into the extensive influence of their standards.

- ISO and AATCC standards are globally applicable.

- Regional bodies tailor standards to specific markets, aligning with regional needs.

Precision in Labeling

From lab to consumer, accurate labeling based on color fastness results is crucial.

- Clear labels communicate vital information to consumers.

- Accurate representation ensures informed decision-making.

Understanding Labeling Regulations

Knowing specific labeling regulations is crucial, as regions may have distinct requirements.

- Comprehending regulations equips manufacturers to comply, fostering transparency.

XI. Emerging Trends and Future Directions in Color Fastness Testing

Colorfastness testing, a linchpin in textile quality assurance, evolves with tech strides. Explore the future trends reshaping this landscape.

Nanotech in Dyeing

Nanotechnology Applications

Manipulating materials at the nanoscale transforms color fastness. Nanoparticles in dyeing processes offer unmatched control over color retention and fade resistance.

Key Benefits

- Improved Adhesion: Nanoparticles heighten dye adhesion, ensuring enduring and stable colors.

- UV Protection: Nanomaterials block UV rays, shielding textiles from sun damage and color deterioration.

- Environmental Resistance: Nanotech imparts resistance to pollutants and harsh weather, preserving vibrant colors.

- Reduced Environmental Impact: Nano-enhanced dyeing consumes less water and energy, aligning with sustainable practices.

Challenges

Despite potential gains, addressing environmental impacts and safety concerns is vital. Stringent regulations and responsible practices are essential for harnessing nanotech’s potential.

Smart Textiles

Color-Changing Technologies

Smart textiles, integrating color-changing materials, redefining color fastness testing. These textiles dynamically shift colors in response to external stimuli, adding an interactive element.

Applications

- Fashion: Revolutionizing fashion with customizable and adaptive designs.

- Automotive: Integrating color-changing textiles in car interiors for aesthetic appeal or temperature indicators.

- Healthcare: Applying color-changing textiles to indicate body temperature changes or medical conditions.

Technological Mechanisms

- Thermochromic Technology: Materials altering color with temperature fluctuations.

- Photochromic Technology: Light-sensitive materials change color in different light conditions.

AI in Color Prediction

Optimizing Outcomes

AI transforms color fastness predictions with advanced algorithms. Analyzing vast datasets predicts color retention and potential issues accurately.

Key Aspects

- Predictive Modeling: Creating models from historical data to anticipate color outcomes before testing.

- Optimization Strategies: Recommending optimal dye formulations and application methods.

- Continuous Learning: AI systems refine predictions over time through continuous learning.

Practical Implementation

Implementing AI in testing protocols demands careful calibration, validation, and ongoing monitoring for reliable predictions.

Applications

Color fastness testing is crucial for ensuring the durability and vibrancy of textiles in diverse industries. Let’s explore its practical applications in key sectors, from fashion to outdoor gear.

Practical Applications Across Industries

Fashion

- Role: Ensures vibrant and enduring colors, vital in fashion.

- Process: Rigorous washing tests to withstand laundering and maintain original hues.

- Impact: Enhances clothing longevity and aligns with consumer expectations for quality.

Automotive

- Importance: Uphold’s aesthetic appeal of vehicle interiors.

- Process: Ensures upholstery, seat covers, and interior fabrics maintain colors despite exposure to sunlight, temperature fluctuations, and spills.

Home Textiles

- Significance: Preserves the appearance and longevity of home textiles.

- Process: Ensures textiles withstand regular washing and environmental exposure.

Outdoor Gear

- Importance: Crucial for performance and durability in harsh conditions.

- Process: Tests fabrics for resistance to weather, UV radiation, and repetitive use.

Key Considerations in Color Fastness Testing for Different Industries

- Intended Use: Tailoring testing protocols based on industry demands and expected textile usage patterns.

- Regulatory Compliance: Adhering to industry-specific regulations and standards for meeting quality benchmarks.

- Innovation in Design: Providing designers the confidence to experiment with colors and materials backed by rigorous testing.

- Brand Reputation: Upholding brand reputation by consistently meeting or exceeding color fastness expectations, fostering customer satisfaction and loyalty.

Environmental Considerations in Color Fastness Testing

Color testing is essential for quality textiles, but it must align with global sustainability goals.

Eco-friendly Dyeing

Responding to environmental concerns, eco-friendly dyeing methods gain popularity:

- Natural Dyes: Derived from plants, insects, or minerals, using less energy.

- Waterless Dyeing: Innovative tech reduces water consumption significantly.

- Low-Impact Dyeing: Choose dyes with minimal environmental impact.

- Recycled Water Usage: Water recycling systems minimize consumption and reduce harm.

Considerations

- Color Retention: Rigorous testing ensures eco-friendly dyes maintain color longevity.

- Testing Protocols: Adjustments may be needed; robust standards encourage adoption.

Waste Reduction

Color testing uses resources, so waste reduction is crucial:

- Chemical Management: Precise dosages, recycling, and proper disposal minimize pollution.

- Efficient Equipment Usage: Regular maintenance reduces waste and environmental harm.

- Recycling Test Samples: Feasible recycling minimizes material waste.

- Energy-Efficient Practices: Tech upgrades in labs reduce energy consumption.

Considerations

- Regulatory Compliance: Align waste reduction with regulations for industry-wide adoption.

- Educational Initiatives: Raise awareness about waste reduction in the textile industry.

The Last Words

In the world of textiles, color fastness is not just a test; it signifies a commitment to quality, innovation, and sustainability. These insights will guide you toward excellence in your products as you navigate the dynamic textile landscape.

For a comprehensive grasp, explore additional resources and stay updated on evolving trends. Wishing you success in your testing and innovation endeavors!