You know that heart-sinking feeling when you pull your favorite t-shirt out of the dryer and find out it now fits your kid sister better than you?

Or how about when that designer blouse suddenly strains across your shoulders post-laundry?

I’m sure we’ve all been victims of shrinkage!

But what if you had the inside scoop to prevent clothing catastrophes like these?

Well, listen up, because today I’m going to spill textile testing secrets and equip you with insider intel to beat shrinkage at its own game!

In the next few minutes, I’ll break down the science behind fabric shrinkage, reveal key industry testing techniques, and provide laundry tips to keep your wardrobe looking fabulous wash after wash.

I’m talking about deciphering clothing care labels, understanding shrinkage rates by fabric type, special tricks used by manufacturers, and also the smart solution for fabric shrinkage tests.

By the end, you’ll have expert knowledge to keep shrinkage from stealing your favorite outfits.

So grab your pen and paper and get ready for Textile Testing 101!

What is the Fabric Shrinkage Test?

So what exactly is the fabric shrinkage test? Well, in simple terms it measures how much a fabric or garment changes size after being washed or exposed to heat. The test reveals the shrinkage rate – that’s the percentage amount it reduces in length and/or width. Knowing the shrinkage rate helps manufacturers and designers compensate so clothes keep fitting nicely after cleaning.

Reasons for Shrinkage

Now, what causes our fabrics to morph like this in the first place? Several culprits are working together…

Fiber content is a big one. Natural fibers like cotton and wool tend to shrink way more than synthetics like polyester. The structure of natural fibers makes them prone to contracting when agitated.

Fabric construction plays a role too. Tightly woven fabrics shrink less compared to loose, open weaves that can distort easily. Knits are generally more vulnerable than wovens too.

Finishing processes can also impact shrinkage. While pre-shrinking treatments reduce further shrinkage, the lack of these finishes can make fabrics shrink more later on.

Heat, moisture, and mechanical agitation are huge contributors. They cause fibers to relax and shrink. Repeated wash and wear cycles compound this effect over time.

Improper care is another reason. Ignoring fabric instructions is asking for shrinkage trouble! Harsh detergents and high heat accelerate fabric distortion.

Even fiber blends can cause uneven shrinkage since the components may shrink differently. This results in a distorted, misshapen fabric.

Shrinkage Rates by Fabric Type

Now that we know why shrinkage happens, let’s explore how much you can expect from various fabric types:

- Cotton – The bad boy of fabric shrinkage! Cotton shrinks a whopping 3-5% on average with subsequent laundering causing further reduction. Some pre-shrunk cottons fare better.

- Wool – Another shrinkage offender, wool tends to shrink a lot – from 10% to 20% depending on handling. Gentle wash methods are a must!

- Linen – Derived from flax fibers, linen has moderate shrinkage rates of 2-5% during initial washes. Later laundering doesn’t drastically alter its size.

- Silk – Delicate silk shrinks much less compared to cotton and wool, generally 1-3%. But silk blends may shrink more.

- Polyester – This synthetic is very shrink-resistant due to its durable fiber structure. Shrinkage is minimal, less than 1%.

- Nylon – Similar to polyester, nylon withstands shrinkage incredibly well. Changes in size are barely detectable at under 1%.

- Blended – Blend shrinkage varies. Rule of thumb: the more natural fiber content, the more it’ll shrink unless pre-treated.

Factors Affecting Shrinkage

Fiber type impacts shrinkage amounts, but other aspects like fabric construction and finishing processes also play a role. Tightly constructed fabrics, like densely woven types or those subjected to shrink-resistance treatments generally maintain their dimensions better. Also, synthetic materials are inherently less prone to shrinkage than most natural ones due to fiber chemistry and durability. These qualities make them ideal for performance wear and industrial applications where shrinkage can’t be tolerated.

Importance of Fabric Shrinkage Testing

The importance of performing thorough textile shrinkage testing procedures simply cannot be overstated.

Proper shrinkage testing helps provide the invaluable assurance that fabrics will maintain their original engineered size and shape specifications even after undergoing repeated laundry or dry-cleaning cycles over time.

This dimensional stability is an especially critical requirement for apparel items where consumers rightfully expect and rely on consistent, unwavering garment sizing throughout the entire usable lifetime of the product.

Without rigorously conducted test protocols, there could be considerable, undesirable variations in finished size.

Which would almost certainly lead to higher levels of customer dissatisfaction and field complaints regarding the poorly performing product.

Additionally, trustworthy fabric shrinkage test data is crucial during the research and development phases.

It helps determine if newly developed fabric constructions and compositions are suitable for specialized applications.

These applications may include bedding textiles or upholstery fabrics.

In such cases, preserving the engineered dimensional properties is vital.

This ensures that the fabric meets performance specifications and satisfies final conversion needs during cutting and sewing operations.

Moreover, textile engineers and researchers heavily rely on accurately generated shrinkage property analytical results.

These results are essential for successfully developing next-generation technologies and manufacturing processes.

The goal is to surpass current limitations and eventually surpass current fabric performance benchmark standards on multiple levels.

Fabric Shrinkage Testing Method

To measure fabric shrinkage accurately, standardized industry testing methods are followed to mimic real-world conditions while providing uniform procedures for fair comparisons across fabric types.

The main testing standards are ASTM and AATCC procedures. These dictate precise protocols for factors like sample sizes, measurement tools, test solutions, equipment settings, and calculation methods. Following normalized guidelines yields reputable shrinkage rates you can trust!

Now let’s explore the two central testing techniques and how they are performed…

( Spoiler ahead: Just keep reading, we will share the disruptive and innovative artifact of shrinkage testing, you can get the shrinkage data within 5 seconds and no manual measurement is required! )

Impregnation Testing Method

The impregnation method examines shrinkage caused by fiber absorption and penetration of water into the fabric. It works by actually wetting fabric specimens under controlled conditions.

First, the fabric samples are cut to specified dimensions – usually at least 6 inches square to give a representative area that can be accurately measured before and after.

Next, the specimens are fully submerged into an impregnation solution that simulates laundering chemicals, temperatures and exposure times. Solutions may contain water, detergents, or other agents outlined in the chosen test standard.

As an example, AATCC Test Method 135 utilizes an all-purpose detergent dissolved in 125°F water as its impregnation liquid. The samples soak for 30 minutes at this temperature to reflect home wash settings.

After impregnation, the sodden samples undergo a drainage period where excess liquid drips off to reach equilibrium moisture levels, just like a spin cycle. This resting phase allows thorough water penetration within fibers to occur.

Now the wet specimens are ready for mechanical action which differs across testing standards. Some methods specify additional immersion steps with various solutions to assess the cumulative effects of repeated laundering.

Finally, once pulled from the impregnation liquid, specimens are carefully drip-dried flat until bone dry, taking care not to tug or distort dimensions. Only then can final measurements be taken to calculate percentage shrinkage properly!

Mechanical Action Method

Meanwhile, the mechanical action technique investigates shrinkage from physical stresses that closely imitate real-world wearing and cleaning.

Again, fabric samples get cut to standard sizes before testing. These then load into specialized mechanical devices that literally stretch, twist, and tumble the fabrics repeatedly via motors and programmed cycles.

Essentially it’s like placing the swatches inside mini washing machines! The intense mechanical agitation stresses fabrics to instigate shrinkage through fiber relaxation much like home laundering does over time.

For example, AATCC Test Method 150-2012 employs rotating stirring vanes submerged in a test solution bath along with fabric specimens. The powerful vanes pummel and churn material swatches for set timeframes and rotation velocities to simulate machine washing friction.

Other mechanical testers rely on pneumatics and tight rollers to repeatedly flex, smooth, and decompress fabric samples at certain pressures and cycling speeds to mimic industrial laundry finishing. This technique assesses shrinkage effects from finishing processes applied after regular washing.

At the end of the intense mechanized sequence, fabrics get removed and laid flat to dry before taking final measurements for shrinkage rate calculations.

Both liquid impregnation and mechanical action methods have a unique value for assessing fabric changes from specific causes like water absorption versus wearing and cleaning friction.

Now you can shrink test like a pro!

Calculating Shrinkage Percentages

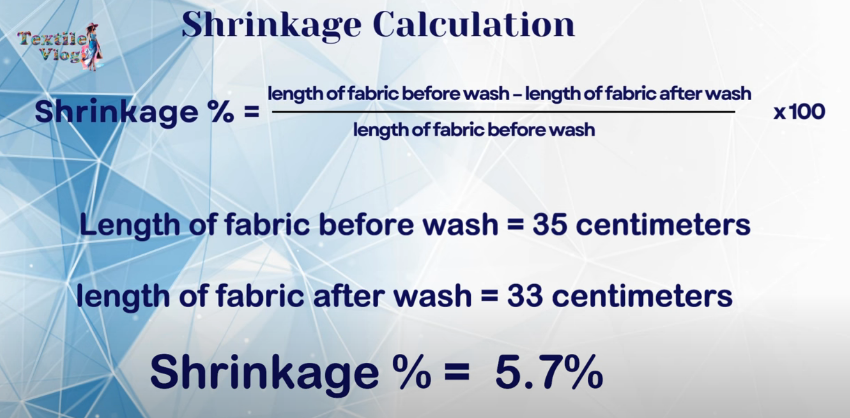

Figuring out the shrinkage rate relies on some simple number crunching. You measure the fabric’s length and width before testing, then remeasure after testing once dry. The percentage difference determines shrinkage.

For example:

Initial width measurement = 45 inches

Final width after testing = 40 inches

Shrinkage % = (Original dimension – Final dimension)/Original dimension x 100

Here that would be:

(45 inches – 40 inches)/45 inches x 100 = 13%

It’s that easy!

How can fabric shrinkage testing be accurate and reliable?

Precise and dependable fabric shrinkage testing is critical in the textile sector.

But how can one guarantee measurements produce trustworthy results?

#1

First, utilize standardized testing protocols. One should follow established industry standards that outline sample preparation, conditioning procedures, and treatment methods like washing, drying, and measurement techniques.

This promotes consistency and comparison with other labs.

Carefully controlling influencing variables too – temperature, humidity, wash, and dry cycles should be precisely regulated to minimize human mistakes.

Also, testing multiple fabric samples, not just one, accounts for normal material variations.

#2

Second, thoughtfully prepare test swatches.

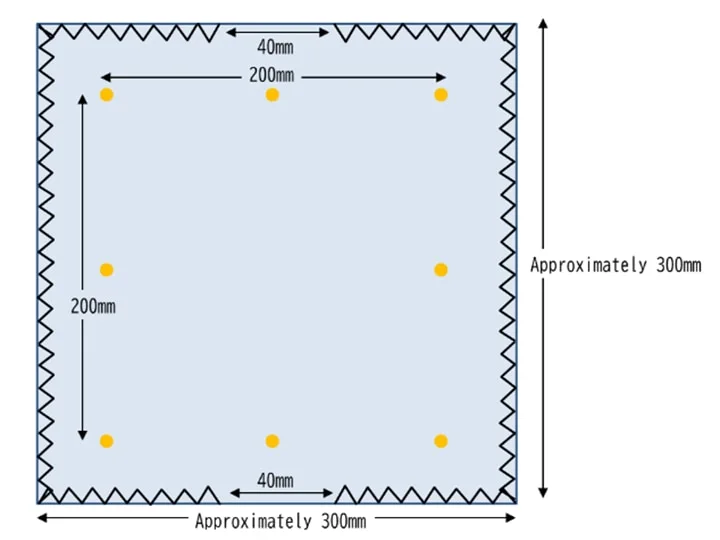

Cutting samples to standard dimensions ensures measurement points align properly pre and post-treatment.

Marking clear reference points before testing helps too.

Additionally, simulating real-life laundry conditions with wash temperature, detergent type, and agitation levels matching eventual consumer use proves important.

#3

Finally, properly analyze and report data.

Employing precise tools like specialized testing machines, rulers and calipers evaluates dimensional changes.

Most importantly, transparently documenting the complete testing methodology, parameters, and measurements in a detailed technical report enables meaningful comparisons with other results.

Diligently following these steps leads to extremely reliable apparel shrinkage results.

This drives better fabric choices, garment construction, and care labeling to safeguard customer satisfaction and brand reputation against unpleasant surprises.

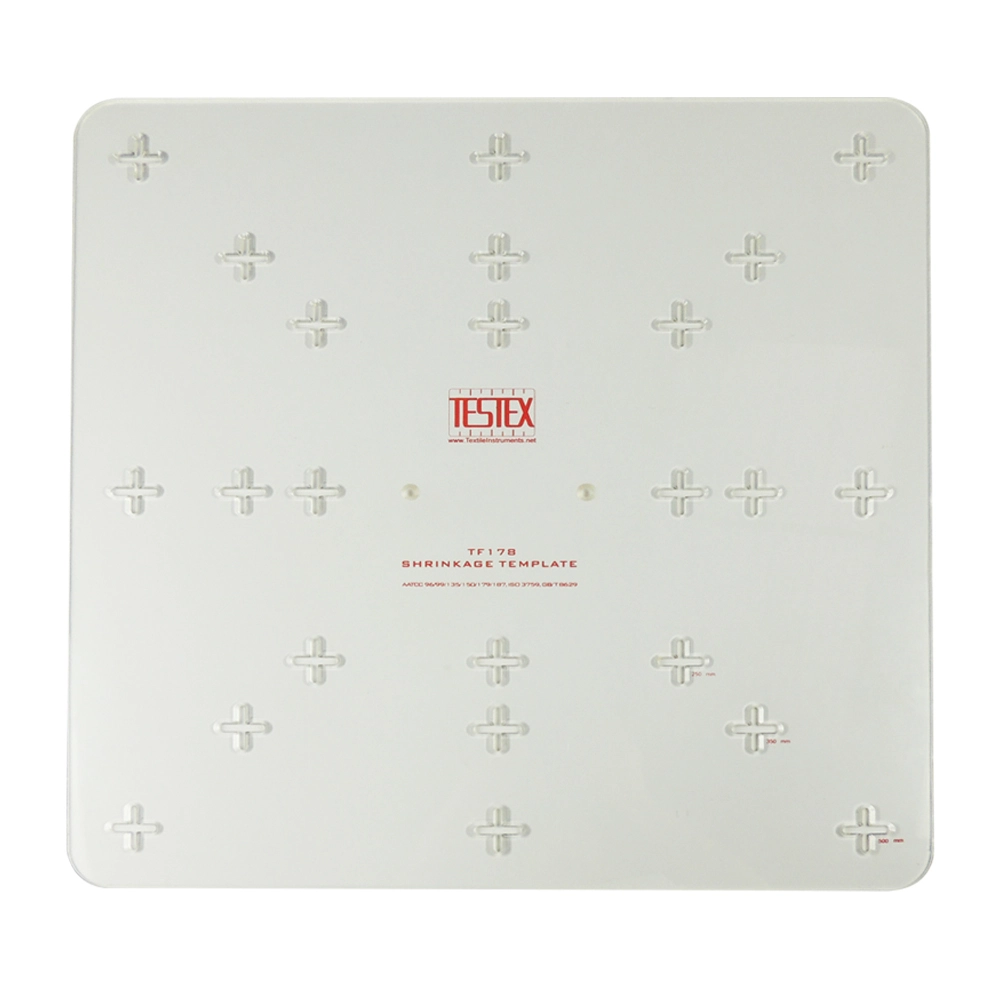

Shrinkage Template Scales

Calibrated shrinkage scales like our TF178 template measure come in handy for taking very precise measurements to calculate shrinkage amounts. They’re durable and portable too – ideal for fabric mills, manufacturers, test labs, and even craft hobbyists.

Features include enhanced accuracy within 1 millimeter, efficient single-user operation, and an easy view of fractional measurements. The dual side markings cater to both inch and centimeter readings. Plus the engraved measurement surface prevents wear and tear over continual use which means consistent, reliable results.

Using shrinkage scales is super easy. Simply place your test fabric or template onto a flat work surface and position the scale ruler edge flush against the specimen. Slide the scale sideways to take measurements across widths, or align it perpendicular to assess length shrinkage. Record the readings before and after shrink testing for comparison. Refer to the product manual for full calibration and care guidance to uphold precision.

With handy tools like these, calculating shrinkage rates is a total breeze!

Smart Solution for Fabric Shrinkage Test

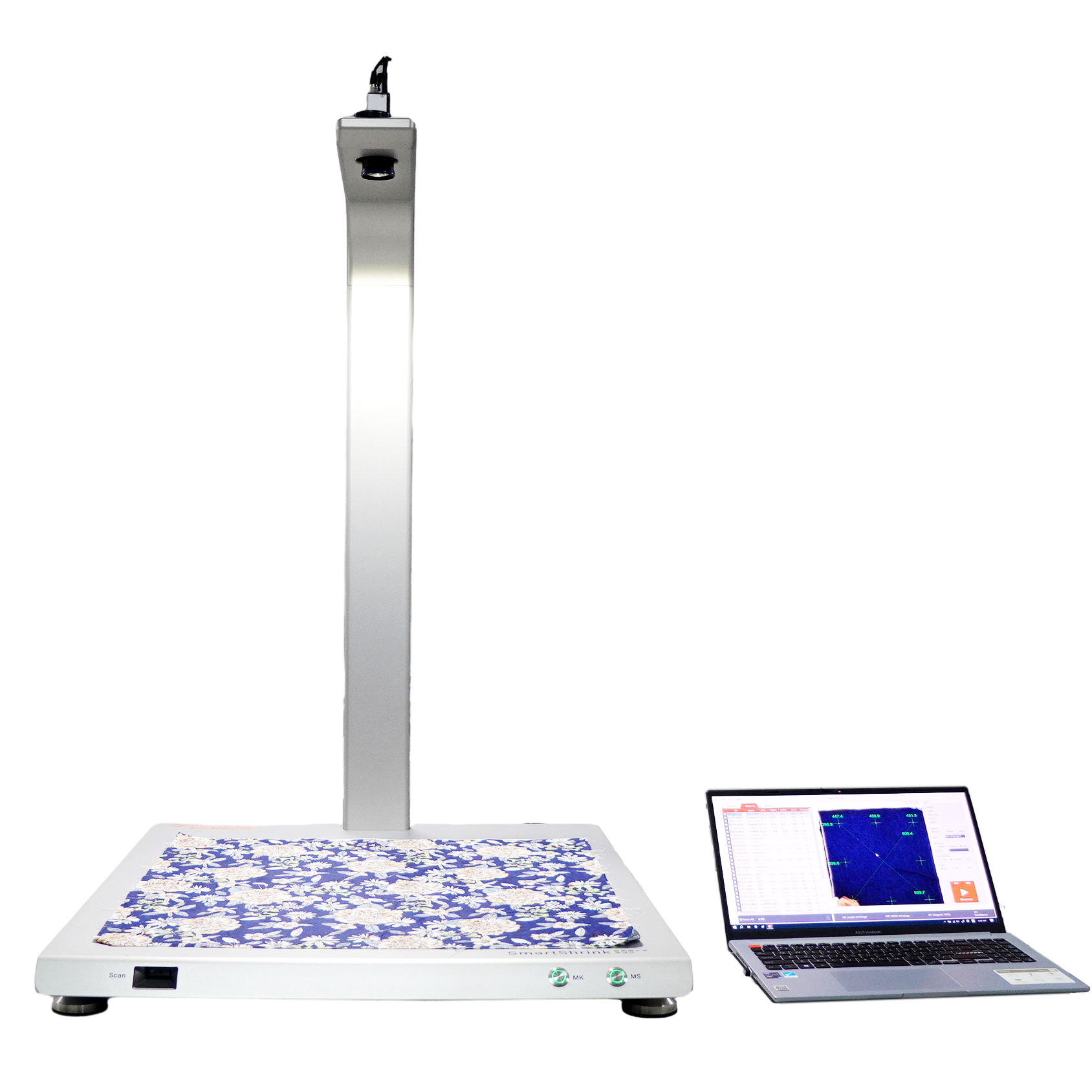

Just choose SmartShrink!

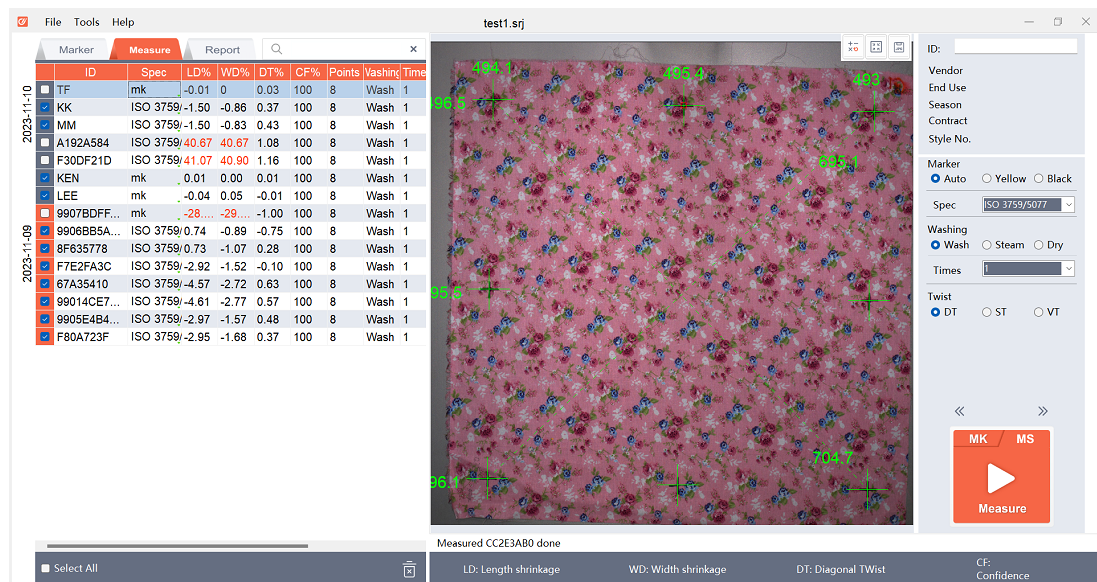

SmartShrink Shrinkage Rate Tester determines multiple shrinkage rate test results in 5 seconds for fabrics after washing, steaming, and dry-cleaning.

SmartShrink takes a picture of a fabric sample by using a camera equipped on the top of the machine, automatically measuring the distances between the marked dots, and calculates the shrinkage rate by the patented vision inspection algorithm of ChiuVention. The test results will be shared with the IoT-connected SmarTexLab app installed on the computer and smartphone.

Why SmartShrink?

The test results are more accurate and reliable.

Using SmartShrink, the test sample is photographed with a high-definition camera, and the distances between the marked dots are automatically measured, The shrinkage rate is calculated with a unique algorithm, yielding all test results in real-time accurately. Even printed fabrics can be accurately recognized and tested.

SmartShrink can be connected to the ERP of the factory or the LIMS system of the testing lab

After connecting through the network port, SmartShrink can upload the test results and sample photos to the ERP or LIMS system, which is convenient for users to manage shrinkage test data.

Save $30,000/year for textile testing labs.

You can get the shrinkage rate data in just 5 seconds by using SmartShrink,

while it takes 6 minutes if you do it by manual measurement and calculation. Thus, SmartShrink can save more than 2 labor costs per year.

Top fashion brands and testing institutes are using SmartShrink now.

Top fashion brands and authoritative testing institutes such as Adidas, Decathlon, Anta, Texwinca, and BV Testing Institute have widely used SmartShrink.

Besides, SmartShrink can output multiple shrinkage data simultaneously, such as warp and weft shrinkage, seam twist rate, vertical twist rate, and diagonal twist rate, as well as credibility rating for the test results. It can evaluate the quality of the fabric more comprehensively.

Which Fabrics Require Testing?

Dealing with a shrunken shirt or ill-fitting pair of jeans can be extremely annoying for all involved.

That’s why shrinkage testing plays a vital role for fabric and apparel companies.

However, not every textile requires the same level of rigor when it comes to testing.

Certain fabrics are prime candidates for evaluation.

Natural fibers like cotton, wool, linen, and silk are infamous for their shrinkage tendencies upon washing or drying.

Cotton may shrink 3-5%, wool 5-10%, linen around 3-5%, and silk up to 8% if exposed to high heat or agitation.

Blended materials also need assessment – the more cotton or wool content, the more shrinkage generally occurs compared to synthetics.

While polyester, nylon, and acrylic intrinsically display minimal shrinkage, testing these man-made fabrics provides quality control and ensures batch-to-batch consistency.

Their presence in blends also heavily dictates overall shrinkage behavior.

Which fabrics must be tested for shrinkage?

For upholstery, industrial, and medical textiles where dimensional stability is paramount, shrinkage control becomes necessary through testing to maintain functionality, efficacy, and safety.

Manufacturers frequently promote “pre-shrunk” materials or recommend care methods to limit shrinkage.

Rigorous testing verifies if their marketing claims hold up.

Finally, fledgling experimental fabrics with uncertain shrinkage properties necessitate testing to properly predict performance and guide usage.

Shrinkage testing’s importance depends significantly on the textile itself – its fiber composition, processing, intended application, and any related manufacturer claims or promises.

Understanding Fabric Shrinkage Testing Standards

Dealing with shrunken shirts or ill-fitting garments can erode customer confidence and frustrate manufacturers alike.

That is why standardized fabric shrinkage testing plays a pivotal role for apparel and textile companies seeking to benchmark quality.

By quantifying fabric dimensional changes during washing, drying, or steam pressing, producers can optimize shrink resistance, enhance functionality, and deliver the right consumer experience.

Globally adopted protocols also ensure uniform test methods for comparison across materials and process improvements.

Let us explore a widely utilized international fabric shrinkage testing standard and the typical equipment required.

Key Details of ISO 6330 Standard

The ISO 6330 standard published by the International Standards Organization outlines a popular standardized system for determining dimensions and shape changes in textiles during washing and drying.

First released in 2000, it specifies critical parameters like sample size, pretreatment, measurement, and conditioning.

The standard aims for reproducible, precise test results even when applied across global laboratories.

Updates in 2021 refined conditioning and sampling requirements while aligning terminology with other ISO standards.

The standard defines three primary shrinkage test methods:

Washing Procedure

This evaluates fabric shrinkage and dimensional changes during machine or hand washing followed by flat drying.

Drying Procedure

Assesses shrinkage and distortions occurring during tumble drying or other drying methods after manual washing.

Ironing Procedure

Measures dimensional alterations during ironing or hot pressing using either steam iron, press, or forming equipment.

Key Test Guidelines

ISO 6330 dictates several key testing prerequisites to enable fair comparisons and analysis.

Sample Dimensions

Fabric samples should measure 500mm x 500mm and have folded edges to avoid fraying and entanglement during washing and drying. Smaller 250mm x 250mm swatches are permitted for special cases like sampling limitations or large-scale fabrics.

Washing Parameters

The standard defines washing machine type, wash temperature, cycle settings, water hardness and more based on textile composition and intended care procedures. For example, it recommends 40°C for machine washing for woolens and silks but 60°C for cotton.

Recording Measurements

Fabric dimensions before and after treatments must be accurately recorded at standard atmospheric conditions using calibrated devices. Common measurements include length, width, and spiral curl dimensions.

Test Equipment Needed

While the ISO standard does not mandate equipment models, certain test instruments are necessary.

Washing Machine

An industrial washing machine allows control of wash temperature, water level, agitation settings, and cycle time. Both front-loading and top-loading machines like those from Alliance Laundry Systems, Unimac, or Electrolux are suitable.

Tumble Dryer

Important for drying fabrics post-washing. Professional dryers from Alliance, Pellerin Milnor, or Dexter Laundry allow programming drying time and temperature to achieve moisture control.

Steam Press

Essential for checking shrinkage during steam ironing or hot pressing. Electrically heated presses from companies like Insty-Press enable pressure, steam, and heat control.

Measurement Tools

Precise fabric measurement pre- and post-treatment is critical. Possible devices include specialty fabric rulers, laser triangulation, 3D scanners, and image analysis software.

Environment Chambers

Strictly control ambient humidity and temperature which can impact fabric dimensions. Programmable chambers from Thermotron or Espec meet ISO test environment requirements.

Implementing the guidelines of ISO 6330 for factors like test materials, processes, conditioning, and measurements allows reliable fabric shrinkage comparisons.

Standardization provides a sound basis for textile quality improvement and realistic consumer care recommendations.

With the right testing infrastructure in place, apparel brands can confidently tackle troublesome shrinkage issues.

What are the different requirements for shrinkage test results for different fabrics?

Shrinkage is quite a complex topic in the world of fabrics.

As we dive deeper into the details, it becomes apparent that acceptable shrinkage levels differ considerably depending on the fabric type.

The diversity can seem daunting initially.

However, as we understand the key factors at play, we can set realistic shrinkage expectations tailored to each fabric’s unique characteristics.

Firstly, the fiber content makes a major difference.

Natural fibers like cotton and wool have a higher predisposition towards shrinkage than synthetic fibers such as polyester.

Consequently, natural fiber fabrics often have wider shrinkage tolerance limits.

For instance, 2-3% shrinkage may be deemed acceptable for cotton whereas synthetics may have sub-1% requirements.

Blends also depend on the ratio – a 70/30 cotton/polyester blend could allow moderately higher shrinkage than pure cotton.

Secondly, the fabric construction plays a pivotal role.

Loosely woven or knitted fabrics shrink more readily than tightly constructed ones.

So a loose linen weave could have more relaxed limits than a dense cotton twill.

Finishing processes also impact dimensional stability.

Pre-shrinking and anti-shrink treatments greatly control shrinkage, warranting stringent test limits.

Additionally, the intended use case and care requirements influence acceptable margins.

Upholstery fabrics demand precise fit so have lower tolerances than garments.

Fabrics with “hand-wash cold” instructions warrant stricter limits than machine-washable ones.

Industry standards provide helpful guidelines but brands often have custom specs aligned to consumer expectations.

As you can see, acceptable shrinkage is far from a straightforward, one-size-fits-all standard.

It’s a multi-faceted outcome reliant on an intricate interplay of factors like fiber type, construction method, care instructions, and utilization.

While this diversity may seem bewildering at first glance, recognizing the underlying drivers allows us to make sense of it.

We can then determine judicious, usage-specific shrinkage criteria for individual fabrics.

This specificity and customization is the key that unlocks effective shrinkage testing and soft materials that truly stand the test of time, wash after wash.

Preventing Shrinkage

Now that we’ve gotten shrinkage savvy, let’s go over some fabric care tips to minimize unwanted shrinkage and maintain awesome clothes:

Care Labels – They’re there for a reason guys! Follow cleaning guidelines on fabric tags religiously to avoid accidental shrinkage. Note washing temperatures, drying methods, bleaching warnings, etc. These labels are personalized for that item’s fiber properties.

Wash Cold – Warm water activates more fiber contraction and distortion than cool. Stick to cold washes whenever possible for shrinkage-prone items. Save hot water for the toughest stains only.

No High Heat – Similarly, limit heat exposure from dryers, irons, or direct sunlight. High temperatures encourage shrinkage by tightening fibers rapidly.

Gentle Detergent – Harsh soaps and excessive agitation promote shrinkage through fiber abrasion and stress. Opt for mild liquid detergents suitable for delicates and add garments loosely in machines for gentle cleaning.

Air Dry – Drip drying discourages shrinkage by limiting heat damage. For items prone to extra shrinkage even after air drying, lay flat initially while slightly damp then reshape to desired measurements.

Stick to these simple rules for fabulously fitting garments all year long!

Common Shrinkage Questions

I get lots of common shrinkage questions, so here are some myth-busting answers to help:

Can you reverse shrinkage? No, unfortunately, shrinkage is permanent. Once the fibers tighten up, you can’t lengthen them again. Prevention is first always!

Do all fabrics shrink? No, fiber content influences shrink potential. Natural fabrics generally shrink much more than synthetic blends or pure synthetics due to fiber durability and molecular structure.

Can shrinkage be prevented completely? While no way to guarantee zero shrinkage, proper handling, and washing methods dramatically reduce chances by minimizing exposure to heat, agitation, and moisture.

What’s an acceptable margin of shrinkage? Acceptable margins vary hugely. Performance athletic wear permits around 1% whereas a standard cotton tee allows nearly 5%. Check particular fabric or industry specifications.

Can shrinkage occur in both directions? You bet! Shrinking and distortion manifest across both fabric length, called the warp direction, and also width, referred to as the weft. Amounts can differ based on fabric construction too.

And there you have it folks! By now you should have the inside scoop on all things fabric shrinkage. Understanding how to measure the phenomenon using industry test methods gives you the power to keep your beloved wardrobe pieces fitting fabulous forever.

Thanks for tuning in and join me next time as we investigate more textile testing secrets!