While wearing it, the fabric above the yarn can hook on other objects and tear. It will either rupture or be partially clamped and torn in half. A fabric tear causes this damage.

Definition of terms

Tearing Strength is the force needed to extend the initial cut in a specimen. This happens under specified conditions. Warp yarns tear. They call their strength ‘warp tearing strength’. Weft yarns tear. They call their strength ‘weft tearing strength’.

Tearing length:

The distance from the beginning of the force application to the end of the cut extension.

Separation length:

The distance between two effective clamping lines on the test device.

Peak value:

The value is where the slope changes from up to down on the force-elongation curve.

Trouser-shaped specimen:

Cut from the center of the short side of the rectangular specimen. Do this to make two trouser-legged fabric tear test specimens. You can clamp them.

Trapezoidal specimen:

Rectangular fabric tear test specimen. Two lines mark the specimen. The lines have specified dimensions. They form an isosceles trapezoid for clamping the specimen. An incision of the specified size cuts the center of the short side of the trapezoid.

Test Standards

The current test standards for the tearing strength test of textiles are national, international, and American. The standards have the following numbers and names:

This is Part 1 of a series on textile fabric tearing. It covers how to test tearing strength using the impact pendulum method (GB/T3917.1-2009).

This is part 2 of a test on how well fabric resists tearing. It focuses on the strength of a single seam in trousers. The test follows standard GB/T3917.2-2009.

This is about the tearing performance of fabrics. It is Part 3. It covers how to measure the tearing strength of trapezoidal specimens. This follows the standard GB/T3917.3-2009.

This is about Part 4 of a test for fabric strength. It measures the strength of a tongue-shaped sample with a double-stitched seam. The test is in the GB/T3917.4-2009 standard.

This is about the tearing properties of textile fabrics. It covers how to measure the tearing strength of wing-shaped specimens with a single seam. It follows the standard GB/T3917.5-2009.

This is about the tearing of fabrics. It is Part 1. It covers the Elmendorf method in ISO13937-1:2000.

This covers the tearing traits of fabrics (ISO 13937-2:2000). It is about the tearing strength of trouser-shaped specimens (single tongue method).

This is a standard for the strength of fabrics. It covers the tearing strength of a wing-shaped specimen. The standard uses the single-tongue method.

This is a standard for the tearing of textiles (ISO 13937-4:2000). It covers the tearing strength of tongue-shaped fabric samples (double-tongue method).

Test Method for Tearing Strength of Fabrics by Elmendorf Tester (ASTMD1424:2009).

This is the Test Method. It is for Determination of Tear Strength of Fabrics by the Tongue (Single Slit) Method. It uses the Constant Speed Tensile Tester. ASTMD2261:2013 describes the method.

This is a test method. It measures the tear strength of fabrics. It uses the trapezoidal method. The test method is in ASTMD5587:2008.

Tear Test

This is about the tearing properties of textile fabrics. It covers how to measure tearing strength. We use the impact pendulum method (GB/T3917.1-2009) to do this.

This is about the tearing properties of textile fabrics. It is Part 1 of the method for measuring tearing strength. The method uses an impact pendulum (Elmendorf) (ISO13937-1:2000).

This test method measures the tearing strength of fabrics. It uses the Elmendorf Tear Tester. The standard is ASTMD1424:2009.

Based on the above standards. Here are the relevant contents and operation procedures:

1. Test principle

The fixture fixes the specimen. The surgeon makes an incision at the specified place. Releasing the pendulum from its position of maximum potential energy. When the movable fixture separates from the fixed one, it tears the specimen along the direction of the incision. The tearing force converts the work done by tearing fabric.

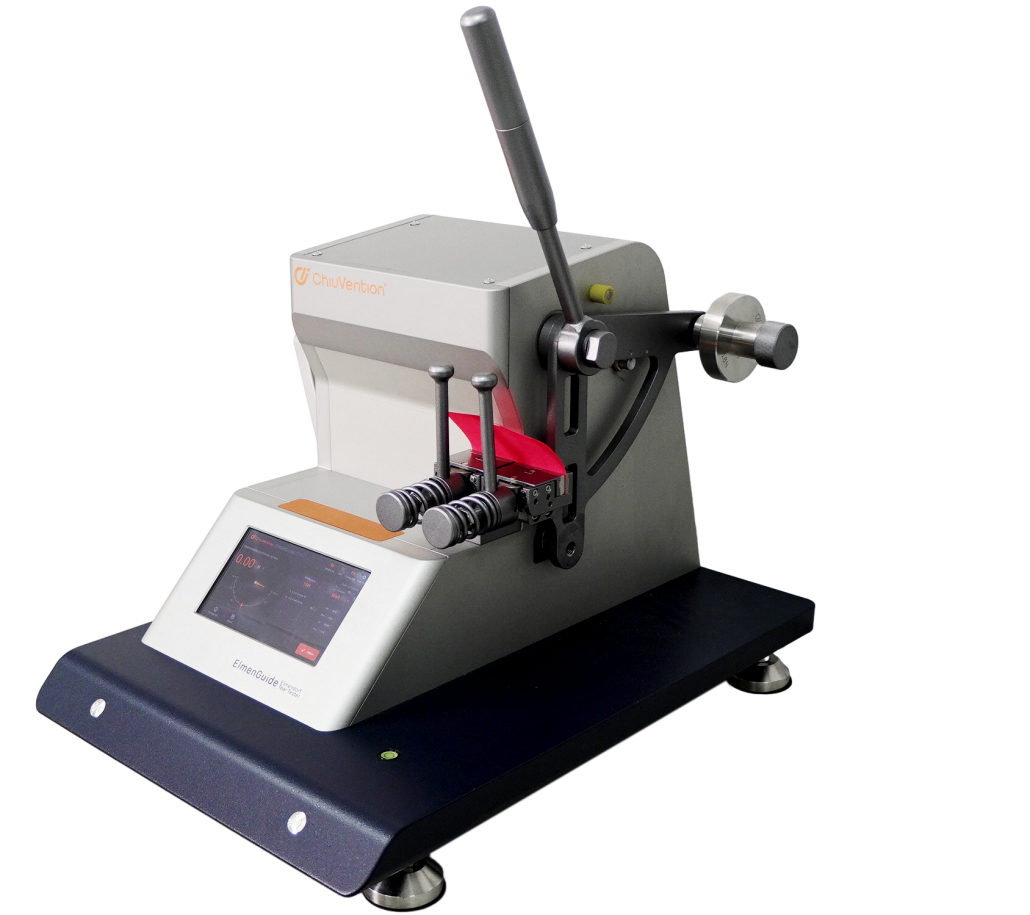

2. Instrumentation

Pendulum tester. The specimen clamps in two fixtures, with one fixture being movable and the other fixed on the frame. Gravity drops the pendulum, which is then attached to the movable fixture and tears the specimen during the tearing strength test without making contact. Cutting tool is best to use the hollow stamping template or sample plate.

3. Moisture adjustment

According to GB/T6529 provisions of the standard atmosphere pre-moisture, moisture and test.

4. Sample preparation

①Cut each laboratory sample into two groups of test specimens, with one group for the warp direction and the other group for the weft direction, ensuring that the short side of the specimen is parallel to the warp or weft direction to guarantee that the tear occurs along the incision. The appropriate names for the direction, such as longitudinal and transverse, designate the samples outside the woven fabric. Each group must include at least five samples, making sure that no two samples have yarns of the same length or width direction, and avoiding taking any samples within 150mm from the fabric’s edge.

② Cut the specimen according to the following figure, making sure to maintain the tear length at 43mm, even if the shape of the specimen may vary slightly.

③Cut each piece of woven fabric specimen so that the short side is parallel to the warp or weft of the fabric. The specimen whose short side is parallel to the warp direction is the ‘weft’ tearing specimen, and the specimen whose short side is parallel to the weft direction is the ‘warp’ tearing specimen.

5. Test procedure

① Select the weight of the pendulum so that the test result of the specimen falls within the range of 15% to 85% of the full scale range of the corresponding scale. Calibrate the zero position of the tearing strength tester.and raise the pendulum to the starting position.

② Mount the specimen: clamp the specimen in the fixture so that the long side of the specimen is parallel to the top edge of the fixture. Clamp the specimen in the centre, gently place its bottom edge to the bottom of the fixture, cut a 20mm notch on the opposite side of the groove with a knife, and the remaining tear length is 43mm.

③ Start the test: Press the pendulum stop button and release the pendulum. Hold the pendulum when it swings back to avoid destroying the position of the pointer, and read the tearing strength in Newtons from the measuring device scale scale value or digital display. The manufacturer of the instrument may specify the appropriate factor that you need to multiply the reading by, depending on the type of instrument used, to convert the result into an expression in Newtons. The result of the check should fall within 15% to 85% of the scale used. Repeat the test at least 5 times in each direction.

After completing the test, observe if the fabric tears in the direction of the force and if the yarn slips from it instead of tearing. A elmendorf tearing test is valid if it fulfils the following conditions:

The yarn has not slipped from the fabric

The specimen does not slip from the fixture

The tear is complete and the tear is always within a 15mm wide groove

Reject test results that do not meet the above conditions, and you cannot use this method if you reject three or more of the five specimens. If you need more specimens, we recommend doubling the number of specimens.

6. Calculation of test results

The impact pendulum method allows direct measurement of the test results, and the tear resistance of the fabric is usually expressed as a force value in Newtons. Convert results expressed in other units to Newtons. We calculate the arithmetic mean value of the tear strength in Newtons for each specimen direction, keeping two significant figures. If required, calculate the coefficient of variation (accurate to 0.1%) and 95% confidence interval, retaining two significant figures, in Newtons. If required, record the maximum and minimum tear strength of the sample in each direction.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: medium@chiuvention.com