Improving textile testing technology includes better methods and innovation. These ensure higher efficiency, accuracy, and reliability in testing textile properties. This can include the use of automated testing tools. They lessen human error and improve precision.

Using advanced software for data analysis offers deeper insights into test results. It helps manufacturers understand textiles’ performance better. Of course, modern technology like AI and 3D can improve testing. They give a more detailed and correct assessment of materials.

Also, we can develop sustainability tests. They measure textiles’ impact on the environment. They support eco-friendly manufacturing.

What is quality control in textile testing?

Quality control in textile testing is a planned process. It ensures that textile products meet the standard and customer expectations. It includes a series of tests and inspections. They happen at many levels of production and find defects. They assess the quality of raw material, semi-finished items, and finished products.

Of course, these tests often evaluate many factors. These include strength, durability, color quality, shrinkage, and chemical makeup. By doing this, manufacturers can keep high standards. And they will also cut waste and please customers. This will improve their brand reputation. Finally, quality control in textile testing is key. It is needed to offer reliable, high-quality textile products. These products must meet rules and customer needs.

Why is quality control important in textile testing?

We need quality control in textile testing. It is needed for many reasons. It helps to ensure the success and reliability of textile products. And it ensures the textile meets industry standards. It also covers regulatory needs and consumer expectations. Here are some of the key reasons why quality control is important in textile testing:

-

Guarantees Product Steadiness

It aids in maintaining consistency in textile products. By testing often, the manufacturer can ensure each batch of textiles meets the quality standard. This consistency is crucial. It helps build brand trust and ensure customer satisfaction.

-

Compliance with Values and Rules

Textile products should obey with different industry standard and regulations. These include related to safety, performance and environmental impact. Its processes ensure that textiles meet these standards. They help manufacturers avoid legal issues and recalls. It also facilitates entry into global markets with stringent rules may apply.

-

Reduces Defects and Waste

Through rigorous QC testing, we can identify defects in raw materials or finished products early. This finding allows for corrective actions. They will reduce defect and waste. The lower defect rates can also make cost savings for producers.

-

Enhances Customer Satisfaction

Of course, top-notch textile products lead to better customer satisfaction. Quality checking makes sure products meet consumer expectations. They must do so in areas like durability, appearance, and performance. Happy customers become repeat buyers. They recommend the products to others. This builds brand loyalty and fame.

-

Improves Efficiency and Productivity

Considering quality control in textile testing can develop the production process. By fixing the quality issues often, the manufacturer can boost their efficiency. They can do this by finding and fixing the issues a lot. The process is reliable. It leads to faster turnaround times. It can effectively meet market demands.

-

Supports Brand Reputation and Competitive Advantage

Steadily quality products will easily enhance the brand’s reputation. In the tough market, a strong reputation for quality can be crucial. It matters because it attracts more customers and allows for higher prices. The QC plays a crucial role in managing and improving the brand’s market position.

-

Facilitates Innovation and Improvement

QC offers valuable data that can be used for constant development and innovation. By analyzing the QC data, the producer can easily spot the trend. They can then make new technologies. They can understand the root of defects in materials. This will help improve product quality.

Testing in textiles needs quality control. It is crucial for ensuring product consistency and deals with many factors. It will boost efficiency and support brand reputation. Thus, it is key for successful textile manufacturing.

Why do you need to test fabric?

Testing fabric is vital for the fabric industry. It ensures the final product meets performance and safety requirements. Here are the important thing reasons why fabric testing is vital:

-

Making sure Quality and Consistency

Fabric testing is crucial for keeping high, exceptional and consistent fabric products. By doing many tests, producers can make sure the material meets the specs and requirements. This consistency is key for logo reputation and consumer pride. Buyers expect the same high quality every time.

-

Meeting Regulatory and protection standards

Textiles should comply with several regulatory and protection requirements, which range by area. Fabric testing allows producers to ensure that their product meets those rules. The rules cover flammability, chemical safety, and sturdiness. Compliance not only avoids problems but also protects clients from ability damage.

-

Assessing overall performance characteristics

Special applications need fabric with specific traits. It needs strength, stretch, breathability, and moisture-wicking. Testing facilitates determining if the fabric possesses those quintessential tendencies. For example, sportswear must be durable and breathable. Upholstery fabric needs to be strong and resistant to wear.

-

Identifying Defects and improving manufacturing

Testing fabrics allows manufacturers to perceive defects early within the production method. By spotting issues like inconsistent shade, pilling, or weak fibers early, agencies can cut waste and save money. They catch the issues before the material becomes finished products. Also, tests show effects. They give insights that could improve manufacturing strategies and lead to better fabrics.

-

Improving customer satisfaction

Purchasers expect magnificent textiles that carry out quality and final lengthy. Testing fabric rigorously can ensure that products meet these standards. This leads to happier buyers who stay loyal.

We need to test materials. This is needed to ensure quality, follow guidelines, and investigate performance. It also helps us find defects and make customers happier. It is a key technique. And it helps make textile products reliable and great.

What types of fabric testing are available?

Testing fabric is a thorough process. It includes many assessments. They evaluate the great performance and protection of textiles. There are many kinds of fabric testing. They handle the unique traits and features of fabrics.

-

Physical testing

This testing includes supremacy checks, which are fundamental for testing material sturdiness. The tensile vigour test checks cloth’s resistance to stress. It shows how much pressure cloth can withstand before tearing. The tear strength test assesses the pressure to keep a tear that has already started in the fabric. It helps to recognize its sturdiness. Also, the abrasion test evaluates how well materials can resist surface wear. It is caused by rubbing. This ability is especially important for upholstery and work wear fabrics. The pilling resistance test shows how likely fabric is to form small balls of fiber on the surface due to wear. This trait is important for keeping a fabric looking good over time.

-

Performance Testing

This testing examines how well fabric meets precise practical necessities. We must assess fabric for water resistance and repellence. This is crucial for outdoor and sportswear fabrics. The water resistant test measures the material’s ability to withstand water under strain. The water repellence test assesses how well the cloth repels water. It does so on its surface without absorbing it. The moisture test measures fabric’s ability to move moisture away from the body. It then spreads it over the cloth’s surface for quick evaporation. This ability is vital for sportswear and activewear.

-

Comfort testing

Comfort testing makes a specialty of the cloth’s potential to offer comfort to the wearer. The air permeability test measures air drift rate through the material. It shows breathability, which is important for garments worn in hot climates. The thermal resistance test assesses the cloth’s insulation ability. High thermal resistance is ideal for cold weather clothing.

-

Chemical Testing

Chemical testing guarantees the cloth’s protection and compliance with policies. The pH test measures how acidic or alkaline cloth is. This can affect pores, skin, and fabric life. Analysis of the chemical composition finds specific substances. These include dyes and finishes in the cloth. It ensures compliance with safety rules and verifies the use of non-toxic substances.

-

Colorfastness testing

It evaluates how nicely the material retains its color below diverse conditions. The washing test measures how well fabric keeps its color after repeated washing. It checks the longevity of the fabric’s appearance. The mild test assesses how well fabric resists fading in light. This is key for door fabric and clothes in sunlight.

-

Dimensional balance testing

Dimensional stability testing assesses how the material keeps its size and shape. It does this over the years. The shrinkage test measures the fabric’s tendency to reduce after washing and drying. By contrast, the stretch and recovery test evaluates the fabric’s ability to stretch and return to its original shape. This ability is important for fabric used in stretch clothes. These clothes include sportswear and swimwear.

-

Flammability Testing

Testing flammability is key for ensuring fabric safety. This is especially true for those used in kid clothes, sleepwear, and home textiles. The flame resistance test measures how easily the material catches fire. It also measures how quickly it burns. This ensures that textiles meet safety standards.

-

Environmental and Sustainability testing

Environmental and sustainability testing addresses the growing demand for eco-friendly textiles. The test assesses the fabric’s ability to decompose. This ability is key for sustainable textiles. We verify recycled content. It ensures the fabric has the claimed percent of recycled materials. This supports transparency in sustainable practices.

A wide range of material testing methods is available. They ensure that textiles meet high standards for quality, performance, and safety. Every test provides valuable facts. They allow makers to make good, fine products. We tailor these products to specific programs and buyer wishes.

How to improve textile testing technology?

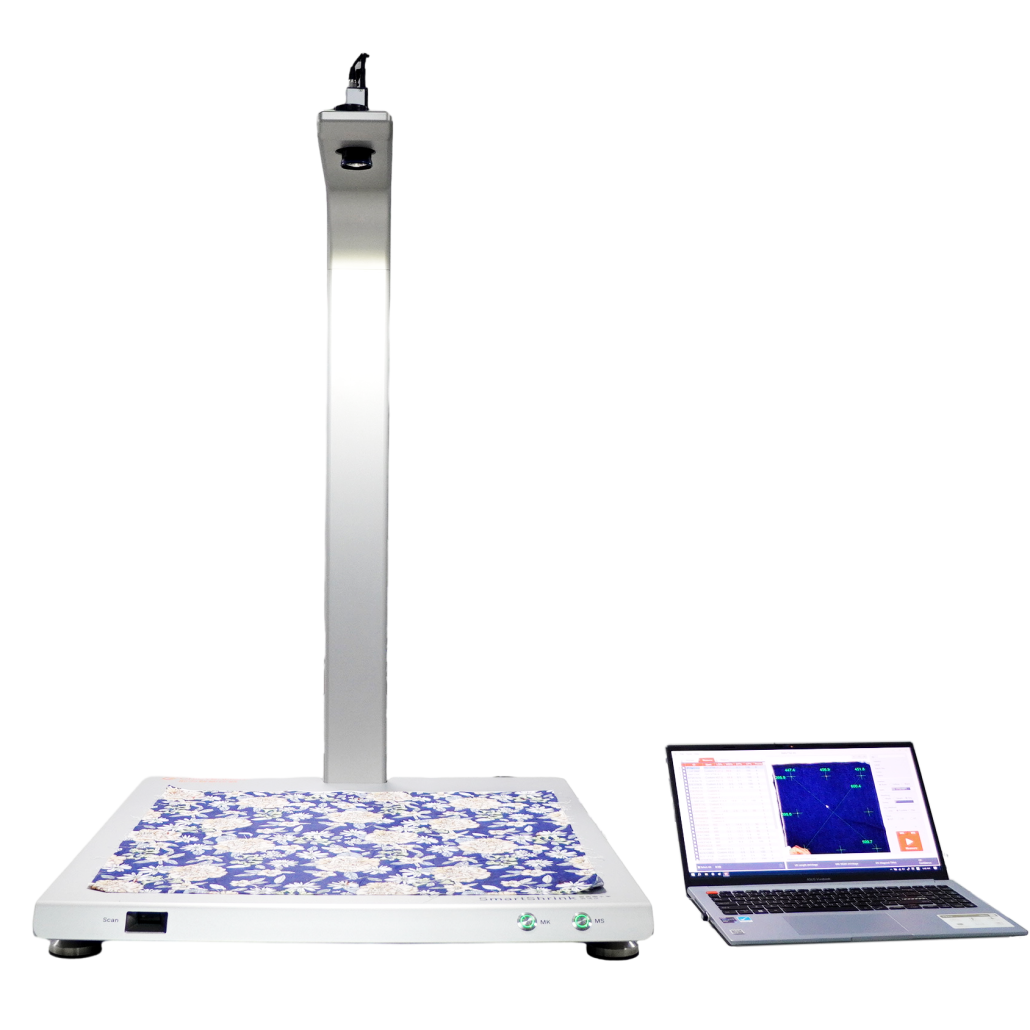

Improving fabric testing tech means adding new methods. It also means using modern ideas to make tests more accurate, fast, and reliable. Automation and digitalization are key. We will use automated testing tools and digital statistics programs. These will lessen human blunders and increase precision. Using 3D imaging and AI can offer extra, accurate tests of material properties. This allows for better predictions of performance and early defect detection.

We need sustainable testing techniques. They must grade the environmental impact of textiles. They are necessary to help production practices. Improving real-time monitoring systems and adding better sensors can offer quick remarks. They help during manufacturing. This ensures steady first-class control.

Why textile testing technology should be upgraded?

Upgrading textile testing technology is essential for multiple causes. First, it gives better accuracy and dependability in picking the best materials. Meeting stricter industry norms and customer expectations necessitate this. New testing tech can miss spread-out flaws and poor performance. Standard methods could find these issues. This can lead to better products and less waste.

Also, modern textile testing tools automate routine tasks and give faster results. This speed is critical for staying competitive in a fast marketplace. It also allows real-time monitoring. It lets manufacturers sense and fix issues right away during manufacturing.

Also, new testing tech allows testing of the latest fabrics and materials in specific places. These include smart textiles and sustainable materials. This power is essential for staying ahead. The need is growing with technical progress.

Similarly, better testing can increase the study of material’s environmental effects. This helps makers launch greener methods and track policies. The company uses boosting fabric testing. This helps them provide better quality. It also improves operations and design. It also helps them contribute to sustainability. In the long run, this leads to better customer satisfaction and a stronger market role.

What is the impact of upgrading fabric testing technology on the textile industry?

Improving fabric testing technology has a big effect on the fabric industry. It improves each product’s quality and efficiency. Special tests show more detail and objectivity. They test the effects of cloth. They let producers provide textiles that consistently meet higher needs and customer expectations. This shows more frequent faults and returns. It also shows growing patron pride and trademark loyalty.

More good testing technology also boosts performance. It does this by automating processes and giving more immediate effects. This decreases the manufacturing period and costs. It lets manufacturers react rapidly to the market and stay competitive. Special sensors and virtual tools enable real-time monitoring systems. They provide quick feedback during production. This allows fast identification and fixing of issues. They also improve product quality and cut waste.

Moreover, elevated testing technology helps creation in the fabric industry. It allows the practical evaluation of current materials. This includes smart textiles and eco-friendly materials. It lets the advancement of existing products. This is perfect for staying relevant. The market likes technical growth and sustainability.

Similarly, better testing can limit the textiles’ impact. It will improve acceptable production. The company must keep with environmental rules. It must also satisfy consumer demand for safe products. This completes the company’s good reputation and marketability. On average, improving cloth testing technology makes the fabric better. It also makes its production faster and more sustainable.

What is the future of textile testing?

The future of textile testing will be balanced. It will be fashioned with special technology and sustainability. Industry and digitalization will resume defeating. They will use smart testing and AI-driven data. These will deliver more accurate, efficient, and dependable results. We know it as real-time media monitoring. It allows instant remarks and fixes during production. It improves quality control.

Sustainability will recreate an essential part. Testing will focus more on environmental impacts. This consists of evaluating the biodegradability of materials and demonstrating using efficient substances. Nanotechnology and smart textiles are improving. They will require new tests. The tests must measure their unique properties and overall performance well.

Also, the many types of blockchain could revolutionize traceability in material testing. They will bring clarity and realism to parts of the delivery chain. Enterprises and academia will work together. This teamwork will cause growth and the development of new testing procedures. In the future, textile testing will be more accurate, implementable, and sustainable. This will meet growing market conditions and regulations.

Conclusion

The evolution of textile testing tech is a key step. It brings us closer to better product quality. It also improves efficiency and sustainability in the initiative. They can ensure more accuracy and speed by using better methods. And they can also use automation and digitalization. They can also better meet regulatory rules. Also, better testing and materials will shape the future of textile testing. They will foster more transparency and environmental duty. The textile industry is ready to deliver better products. It achieved this by continuous innovation and collaboration. These goods will be greater and more sustainable. They will meet the evolving desires of buyers and the planet.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: medium@chiuvention.com