Children’s skin is delicate and sensitive. So, the safety and quality of their clothing are critical. These clothes come into direct contact with their skin, so we must focus on them. Testing clothing fabrics helps us choose materials that work well for kids’ skin. This way, we can lower the risks of allergies and abrasions. Children’s clothing testing is crucial. It helps shape how designers create, produce, and sell clothes. Manufacturers and brands can pick safer, comfier fabrics based on test results. Consumers can select clothes that fit their children’s skin better. This helps reduce health risks from poor-quality children’s clothing. It also builds trust from the source to the end user.

International children’s clothing testing standards primarily emphasize safety. The team reviews material safety, design safety, and garment production by clothing makers. They also consider market rules and other key areas. Testing standards for children’s clothing vary by country. However, they all focus on keeping kids safe. This paper will cover common types of children’s clothing fabrics. We will summarize the main international standards for testing these garments. We’ll also highlight common testing issues and offer solutions. Our goal is to help improve product quality. This will also help parents pick safe and comfy clothes for their kids.

Common Children’s Clothing Fabric Types

Here are ten common fabrics for children’s clothing. This list is for reference only:

Cotton

- Advantages: natural fabrics, comfortable to wear, breathable, high warmth, strong moisture absorption

- Disadvantages: easy to wrinkle, high shrinkage rate is high, easy to mold and mildew, prolonged exposure to sunlight will reduce the strength of the fibers, making be hard and brittle

Organic cotton

- Advantages: no pesticide residues, environmentally friendly, friendlier to sensitive skin

- Disadvantages: high cost, few color choices

Polyester

- Advantages: wear-resistant, wrinkle-resistant, quick-drying, not easily shrinkable

- Disadvantages: poor breathability, hard feel, not as skin-friendly as natural fibers

Cotton + spandex (elastic cotton)

- Advantages: comfortable and elastic, not tight, suitable for sports, and children’s clothing

- Disadvantages: elasticity may decrease after a long period, the cost of the cloth is slightly higher than that of pure cotton

Single-sided knitted fabric

- Advantages: soft, lightweight, breathable, commonly used in T-shirts

- Disadvantages: less elastic, easy to roll the edges, poor support

Double knitted fabric

- Advantages: feels thick, elastic, and not easy to roll the edge

- Disadvantages: not as thin and light as the single-sided fabric, slightly weaker breathability

Corduroy

- Advantages: warm, wear-resistant, textured, suitable for children’s clothing in the fall and winter

- Disadvantages: non-breathable, easy to fall out of the hair after washing, slow drying

Coral Velvet / Rocker Fleece

- Advantages: soft, warm, fluffy, quick-drying

- Disadvantages: prone to static electricity, pilling, not suitable for close to the body

Terry cloth (French terry)

- Advantages: sweat absorption, breathable, elastic, suitable for sports, and children’s clothing

- Disadvantages: easy to hook and loop, the surface is not smooth enough

Tencel / Lycra

- Advantages: silky, breathable, anti-bacterial, and environmentally friendly, excellent skin feel

- Disadvantages: easy to wrinkle, the requirements of the washing method are high, and the price is high

Common Items Tested on Children’s Clothing

Chemical Safety Category

Children’s clothing touches their skin, so its chemical safety is very important.

Testing items usually include:

- Formaldehyde levels

- pH value

- Decomposable aromatic amine dyes

- Heavy metals, such as lead and cadmium.

- Odor tests

We must control these harmful substances. They can cause skin sensitization and respiratory irritation. If levels are too high, they may lead to more serious health risks.

Color Fastness of Clothing

Brightly colored clothes for kids capture their attention. However, dyes that lack colorfastness can wash out with ease. This may harm their skin or mouth. Someone must conduct testing for colorfastness on children’s clothing. Key tests check resistance to water, sweat, friction, and saliva. This is especially important for infants and young children. These checks help keep colors bright and prevent harmful substances from being released. This protects children’s safety.

Physical Safety

Physical properties help measure how durable and safe children’s clothing is. The main tests include:

- Tensile strength

- Shrinkage

- Abrasion resistance

- Sewing firmness

- Component safety (such as verifying whether small ornaments can detach with minimal force)

- Look for hidden dangers in zippers and drawstrings.

These can pose risks like entanglement or strangulation, and help us lower the risk of damage and safety hazards while wearing the product.

Labeling

Labeling isn’t a technical test. It is the first line of defense for product legal compliance and for building consumer trust. Labeling is the first line of defense against legal compliance and consumer trust. It covers the completeness and accuracy of important details. This addresses clothing components, safety types like Class A and Class B, rules for use, and washing tips. Compliance labeling aids regulators in their reviews. It also offers consumers clear guidance for buying. For children’s clothing, retailers must install strict content controls before selling it.

Children’s Clothing Testing Procedure and Corresponding Instruments

Formaldehyde Content Testing

- Detection Methods: Gas Chromatography, Acetyl Acetone Spectrophotometry, etc.

- Instrumentation: Formaldehyde Test Fabric Sample Precision Cutter

- Function: Sense formaldehyde in textiles to keep children’s skin and airways safe.

Flame Retardant Test

- Test Methods: Vertical Combustion Method (e.g., GB/T 14644, ISO 6941)

- Instrumentation: UL94 Horizontal Vertical Burning Tester

- Function: Test how well the fabrics burn when exposed to fire. This ensures that children’s clothing is safe in certain situations.

Color Fastness to Washing

- Test Methods: ISO 105-E01 / GB/T 5713

- Instrumentation: WashTrue Washing Color Fastness Tester

- Function: To check if clothing color fades in the wash and to stop dyes from staining the skin.

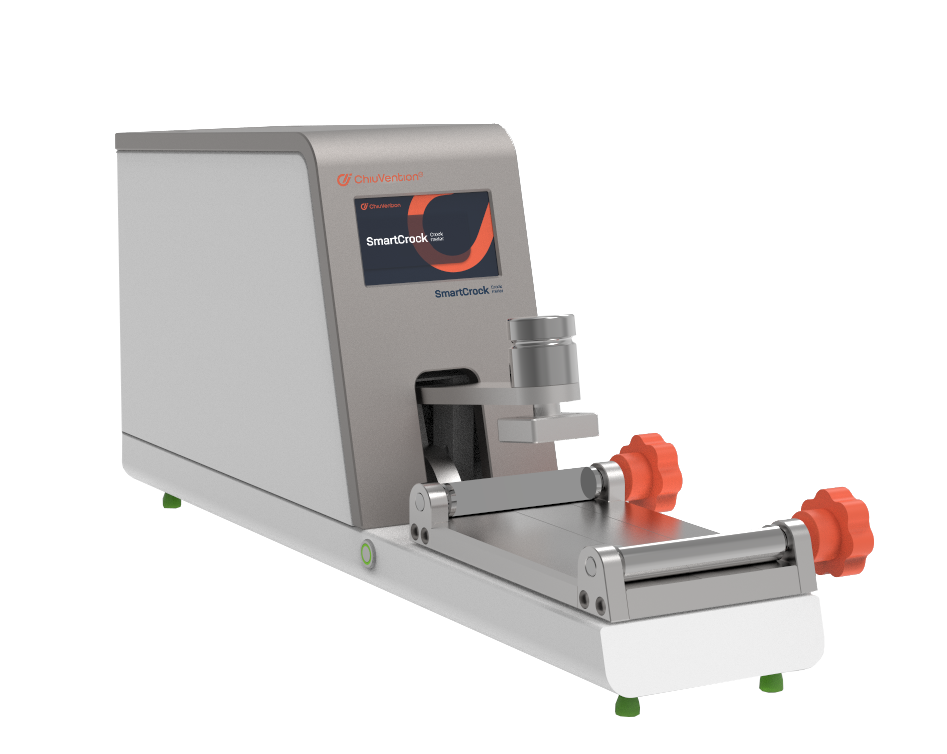

Color Fastness to Rubbing

- Test Methods: ISO 105-X12 / GB/T 3920

- Instrumentation: SmartCrock Crockmeter

- Function: To check if clothing color fades in washing and to stop dye from staining the skin.

Zipper Strength, Cord Safety

- Testing Method: Tensile Strength Test (ASTM D2061 / GB/T 23315, etc.)

- Instrument: SmartPull Tensile Tester

- Function: To test the firmness of zippers, cords, buttons, and other garment parts. This helps stop them from falling off or getting tangled. This way, safety accidents are less likely.

Pilling Test

- Testing Method: ISO 12945 (Martindale Method)

- Instrument: Smartindale Martindale Abrasion & Pilling Tester

- Function: Test fabric pilling from friction. This checks the quality and comfort of children’s clothing.

Shrinkage Test

- Testing Methods: GB/T 8630, ISO 5077, etc.

- Instrumentation: SmartShrink Shrinkage Rate Tester, Constant Temperature Washing Machine

- Function: Measure how much garments shrink after washing. This helps to avoid discomfort and keeps them from losing shape.

Ingredient content

- Testing method: chemical qualitative analysis / solvent combustion method

- Instruments and equipment: microscope, infrared spectrometer (IR)

- Function: to check if the actual fabric matches the label. This helps to prevent false labeling and mislead consumers.

Common test standards for children’s clothing fabrics

Children’s clothing fabrics undergo many performance tests. The main standards are AATCC from the U.S., ISO, and ASTM from the American Society for Testing and Materials. Here are the key tripartite standards for these fabrics:

Colorfastness category

Water fastness to color fastness/fastness to water stains

- AFSL: AATCC 107

- European standard: ISO 105 E01

- Chinese National Standard: GB/T 5713

Test Objective: To evaluate the color stability of fabrics under wet conditions.

Test Principle: Soak the specimen with the lining fabric. Dry it at the right pressure and temperature. Then, check for color changes and staining.

Color fastness to rubbing

- American Standard: AATCC 8

- European Standard: ISO 105 X12

- Chinese National Standard: GB/T 3920

Test Purpose: To test whether the fabric loses its color under dry/wet rubbing conditions.

Test Principle: Rub the standard white cloth and the specimen on the white cloth. Then, check for any color stains.

Scope of application: This applies to all printed, dyed, or color-woven fabrics and yarns.

Physical Property Category

Zipper Strength Test

- American Standard: ASTM D2061

- European Standard: ISO 12802

- Chinese National Standard: GB/T 23315

Test Objective: To see how well zippers hold up when pulled together or apart many times.

Test Principle: Use the tensile machine to test how the zipper opens and closes and to check the strength of the slider.

Cord safety

- American Standard: ASTM F1816

- European Standard: EN 14682

- Chinese National Standard: GB 31701

Test Objective: Check for safety risks in kids’ clothing. Focus on the hats and waist cords that may cause entanglement or strangulation.

Scope of application: This is for children’s clothing made for kids under 14 years old.

Pilling Performance Test

- American Standard: ASTM D 4966

- European Standard: ISO 12945

Test Objective: To measure how many hairballs appear on fabric surfaces after rubbing.

Shrinkage test:

- AFSL: AATCC 135

- European Standard: ISO 6330

- Chinese National Standard: GB/T 8629

Test Objective: To measure the dimensional change of fabrics after washing.

Test Principle: Measure how much the specimen’s size changes after washing and drying.

What do manufacturers/testing organizations need to be aware of?

Manufacturers play a key role in making children’s clothing. They must choose fabrics that are safe and friendly to the skin. This means avoiding harmful substances like formaldehyde and heavy metals.

In production, control the use of chemical additives for dyeing and printing. Regular testing of samples ensures that products meet safety standards.

Product labels need to show safety categories, fabric content, and washing instructions clearly. This helps make the shopping experience more transparent for consumers.

Testing organizations must have CNAS, CMA, and other qualifications. Their production processes should meet national standards. They must issue reports that have legally binding authority. Also, they should use calibrated equipment to ensure accurate and reliable test results. Children’s clothing fabrics must focus on formaldehyde, pH levels, and other chemicals. Testing organizations should check if these fabrics are for baby products. They also need to ensure a safe testing environment and provide good services.

How can consumers tell if it’s safe?

Consumers are the final link in the children’s clothing service chain. They have the right to choose. They also need basic judgment skills. When choosing children’s clothing, check the label. Also, consider the smell, feel, and workmanship. These factors help you assess the product’s quality and safety. Also, look for brands that have quality inspection reports and a good reputation. This can help keep children’s clothing safe and comfortable.

Conclusion

Children’s clothing quality affects their health and safety. Testing is a must for regulations and shows brand responsibility. Manufacturers should keep a close eye on raw materials and their processes. Testing groups must follow standard procedures and give accurate data. Consumers can look at labels and quality reports. They can use this information to choose safer and more reliable products. In the future, the children’s clothing industry must unite. They need to improve standards for quality and sustainability.