The performance and testing of materials are the core foundation for the development of the textile industry. From the selection of fibers to the final formation of fabrics, every link relies on precise control of material properties and rigorous experimental verification. With the rapid development of textile technology, new materials and processes are emerging in an endless stream, and the corresponding performance indicators and testing methods are constantly being updated.

From traditional natural fibers to modern high-performance synthetic fibers, and from simple physical property textile tests to complex chemical structure analyses, the scope of textile material properties and tests is expanding day by day. However, these terms are often highly professional and complex, making it difficult for beginners in the industry, students majoring in related fields, and ordinary readers interested in textiles to understand them.

This article provides readers with a systematic, comprehensive, and easy-to-understand detailed explanation of textile material property and textile testing terms, explained in concise and clear language. Whether it’s the fineness and strength of fibers, the air permeability and moisture absorption of fabrics, or various complex testing methods such as tensile tests and abrasion resistance tests.

Related Terms and Requirements

Pilling

After a fabric pills, the fiber ends on the surface entangle with each other to form raised, opaque balls that can cast shadows.

- GB/T 4802.1 – 2008 Textiles – Determination of fabric pilling property – Part 1: Circular – track method

- GB/T 4802.3 – 2008 Textiles – Determination of fabric pilling property – Part 3: Pill – box method

- GB/T 4802.4 – 2020 Textiles – Determination of fabric pilling property – Part 4: Random tumble method

- GB/T 4802.2 – 2008 Textiles – Determination of fabric pilling property – Part 2: Modified Martindale method

- FZ/T 98022 – 2021 Circular – track method fabric pilling property tester

- FZ/T 95028 – 2019 Pilling machine

- FZ/T 98019 – 2018 Tumbling – box type fabric pilling property tester

- FZ/T 98014 – 2016 Martindale abrasion and pilling property tester

Pilling resistance

The ability of a fabric to resist pilling.

Thermal resistance

The ratio of the temperature difference between the two sides of a test specimen to the dry-heat flux passing vertically through the unit area of the test specimen.

- GB/T 38426 – 2019 Test methods for thermal resistance and use temperature of sleeping bags

- GB/T 24254 – 2009 Determination of required thermal resistance of textiles and clothing in cold environments

- GB/T 11048 – 2018 Textiles – Determination of thermal and moisture resistance under steady-state conditions (Evaporative heat plate method)

- FZ/T 01029 – 1993 Determination of thermal and moisture resistance of textiles under steady-state conditions

- FZ/T 98015 – 2017 Textile thermal and moisture resistance tester

Water vapour resistance

The ratio of the water – vapor pressure difference between the two sides of a test specimen to the evaporative heat flux passing vertically through the unit area of the test specimen.

Water vapour permeability index

The thermal resistance of a test specimen divided by the ratio of the water – vapour resistance of the test specimen to the thermal resistance of air divided by the water – vapour resistance of air. The value ranges between 0 and 1. A water – vapour permeability index of 0 means the material is completely impermeable to moisture and has a very high moisture resistance; a value of 1 means the ratio of the thermal resistance and water – vapour resistance of the material is the same as that of air with the same thickness.

Thermal conductivity

When there is a unit temperature difference between the two sides of a test specimen, the amount of heat passing through the unit area and unit thickness of the test specimen per unit time, which is the reciprocal of the thermal resistance of unit thickness.

CLO value

Under the conditions of a room temperature of 21°C, a relative humidity of less than 50%, and an air flow of 10 cm/s (no wind), when a test subject sits still with a basal metabolism of 58.15 W/m² (50 kcal/m²·h), feels comfortable and maintains an average body surface temperature of 33°C, the thermal insulation value of the clothes worn at this time is 1 CLO value.

- FZ/T 73016 – 2020 Knitted warm – keeping underwear with filling

- FZ/T 73022 – 2019 Knitted warm – keeping underwear

- FZ/T 73054 – 2015 Warm – keeping socks

- FZ/T 70011 – 2006 Marking of knitted warm – keeping underwear

- FZ/T 64088 – 2022 Agricultural thermal – insulation composite fabric

- FZ/T 64002 – 2021 Composite thermal – insulation material – Metal – coated composite flocs

- FZ/T 64006 – 2015 Composite thermal – insulation material – Wool composite flocs

- FZ/T 52028 – 2013 Phase – change thermal – insulation viscose staple fiber

- FZ/T 64020 – 2011 Composite thermal – insulation material – Chemical fiber composite flocs

- FZ/T 60013 – 1993 Determination of thermal insulation property of metallized textiles

Heat retention

The ability of a test specimen to maintain the temperature of the covered object. It is expressed as the percentage of the ratio of the heat dissipation without the specimen to the heat dissipation with the specimen.

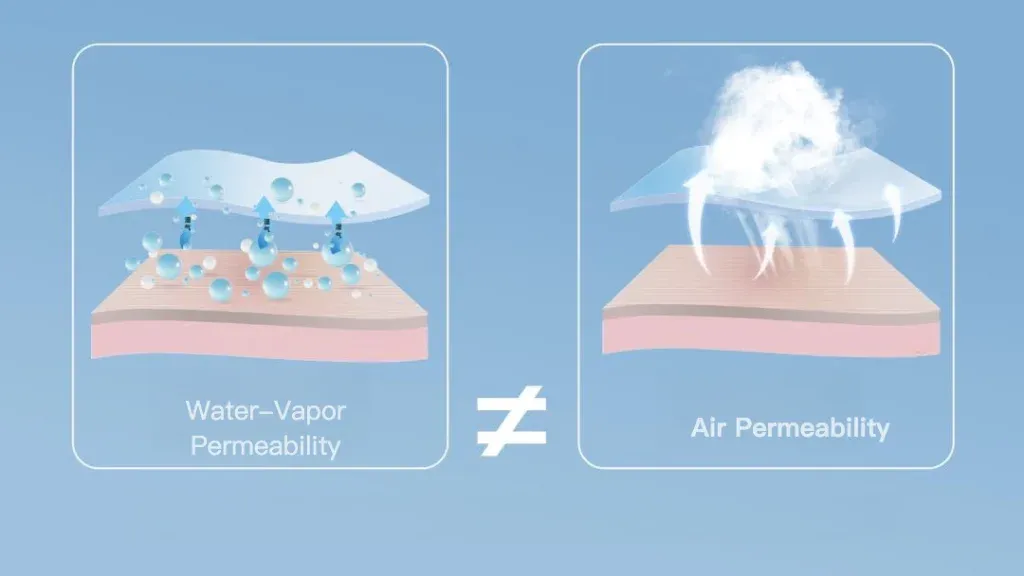

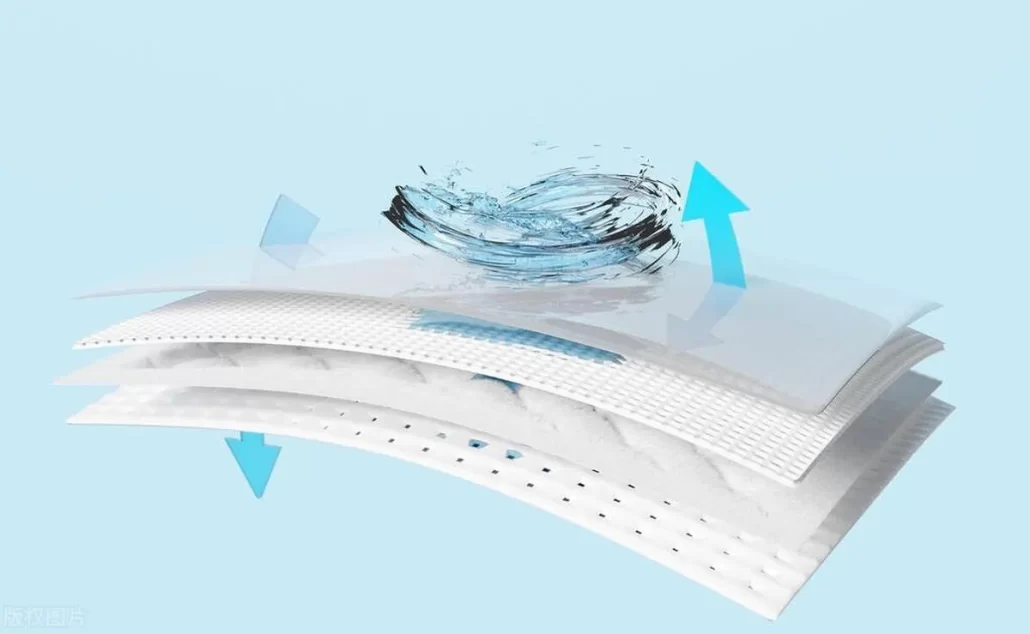

Water vapour permeability

The ability of a test specimen to transmit water vapor. It is expressed as the amount of water vapor passing through the unit area of the test specimen within a specified time under the condition of a water vapor pressure difference between the two sides of the test specimen.

- GB/T 40910 – 2021 Evaluation of waterproof and moisture – permeable properties of textiles

- GB/T 12704.1 – 2009 Textiles – Test methods for fabric moisture permeability – Part 1: Absorption method

- GB/T 12704.2 – 2009 Textiles – Test methods for fabric moisture permeability – Part 2: Evaporation method

- FZ/T 14057 – 2023 Nylon – spandex waterproof and moisture – permeable composite fabric

- FZ/T 14023 – 2021 Polyester (nylon) waterproof and moisture – permeable raincoat fabric

- SN/T 5343 – 2021 Functional testing of imported and exported textiles – Waterproof and moisture – permeable property

- HG/T 5877 – 2021 Thermoplastic polyurethane (TPU) pellets for waterproof and moisture – permeable films

- FZ/T 01149 – 2019 Evaluation of wind – proof and moisture – permeable properties of textiles

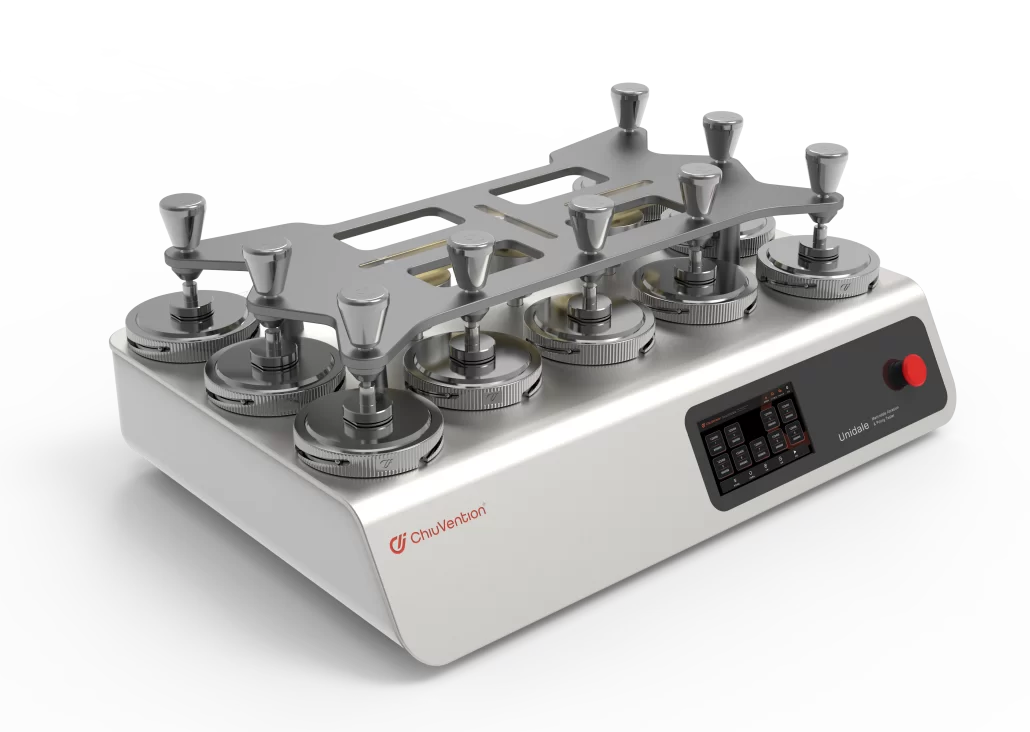

- FZ/T 98020 – 2019 Fabric moisture – permeable property tester

- FZ/T 81023 – 2019 Waterproof and moisture – permeable clothing

- GA 362 – 2009 Waterproof and moisture – permeable composite fabric for police uniforms

Water permeability

The ability of a test specimen to transmit water. It is expressed as the amount of water passing through the unit area of the test specimen under the conditions of a specified pressure difference and time.

- GB/T 4744 – 2013 Detection and evaluation of waterproof properties of textiles – Hydrostatic pressure method

- GB/T 20463 – 2015 Specification for rubber or plastic coated fabrics for waterproof clothing

- FZ/T 14009 – 2024 Dyed waterproof canvas for awning made of vinylon

- FZ/T 14057 – 2023 Nylon – spandex waterproof and moisture – permeable composite fabric

- FZ/T 14056 – 2023 Dyed waterproof canvas interwoven with polyester yarn and polyester industrial filament

- FZ/T 14055 – 2023 Dyed waterproof canvas made of polyester

- FZ/T 14023 – 2021 Polyester (nylon) waterproof and moisture – permeable raincoat fabric

- FZ/T 14021 – 2021 Waterproof, oil – resistant, stain – resistant, and non – ironing printed and dyed fabric

- FZ/T 98021 – 2019 Textile waterproof property tester – Hydrostatic pressure method

- FZ/T 81023 – 2019 Waterproof and moisture – permeable clothing

- FZ/T 64036 – 2013 Sodium – bentonite composite waterproof liner

- FZ/T 14009 – 2013 Dyed waterproof canvas for awning made of vinylon

- FZ/T 01004 – 2008 Determination of impermeability of coated fabrics

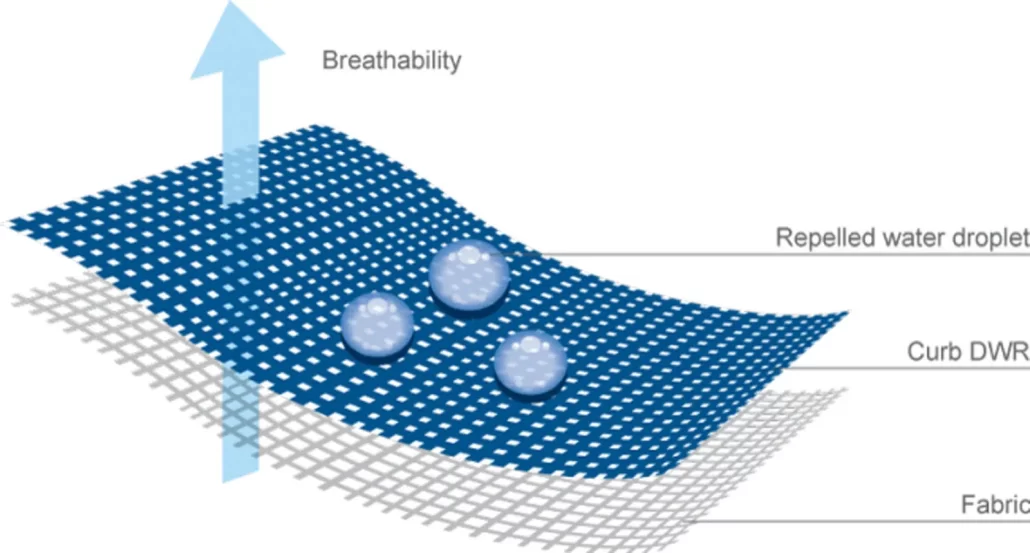

Air permeability

The ability of a test specimen to transmit air. It is expressed as the rate at which air flows vertically through the test specimen under the test conditions of a specified area, pressure difference, and time.

- GB/T 5453 – 1997 Determination of fabric air permeability of textiles

- GB/T 40357 – 2021 Determination of air permeability of hair products – Wigs

- GB/T 24218.15 – 2018 Textiles – Test methods for non – woven fabrics – Part 15: Determination of air permeability

- FZ/T 34015 – 2022 Natural moisture – absorbing and breathable hemp textiles

Water repellency

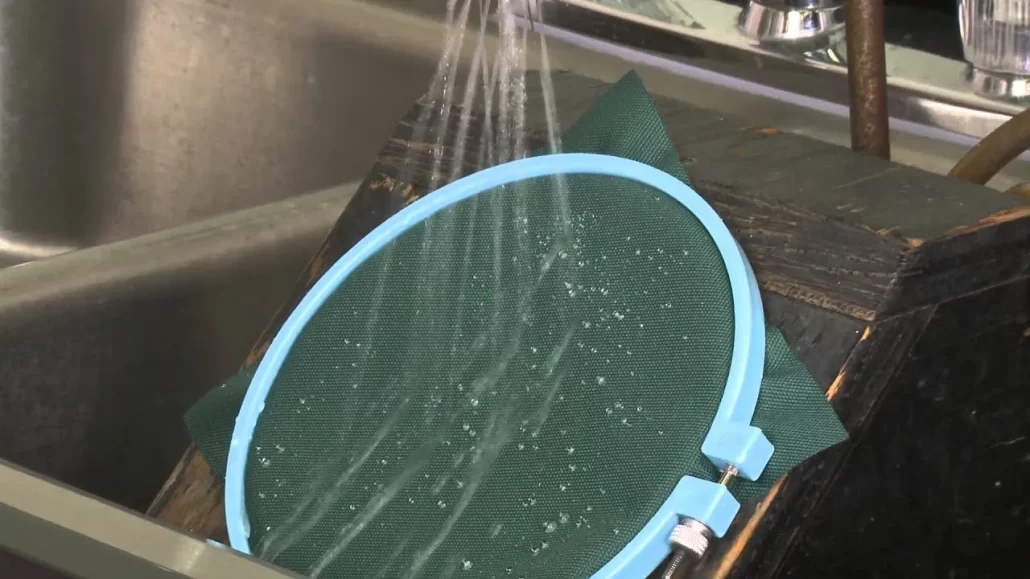

The ability of a fabric to resist the absorption of sprayed water. It is characterized by the degree of wetting on the fabric surface or the amount of water absorbed by the fabric within a specified time under a designated artificial shower.

- GB/T 33732 – 2017 Determination of water impermeability of textiles – Impact penetration test

- GB/T 24218.17 – 2017 Textiles – Test methods for non – woven fabrics – Part 17: Determination of water impermeability (Spray impact method)

- YY/T 1632 – 2018 Test method for water resistance and impact penetration of medical protective clothing materials

- AATCC42 – 2017 Water repellency: Resistance to water penetration test

Spray rating

A measure of the surface water resistance of a fabric.

- GB/T 4745 – 2012 Detection and evaluation of waterproof properties of textiles – Spray test method

Durable press fabric

A fabric that can be restored to a wearable or usable state with only light ironing or without ironing after being washed at home.

Wash and wear

The property of clothing to maintain its original flat appearance without ironing or with minimal ironing after repeated wearing and proper home laundering.

Dimensional change

The change in the length or width dimension of a test specimen under specified conditions.

Cold crack temperature

The temperature at which cracks such as cracks and broken lines begin to appear on the coated surface of a coated fabric when it is impacted at low temperatures.

- FZ/T 01007 – 2008 Determination of low – temperature resistance of coated fabrics

Oil repellency

The property of a fabric to resist the wetting of oily liquids.

- GB/T 19977 – 2014 Textiles – Oil repellency – Hydrocarbon resistance test

- FZ/T 24012 – 2021 Water – repellent, oil – repellent, and stain – resistant cashmere knitted products

- FZ/T 14021 – 2021 Waterproof, oil – resistant, stain – resistant, and non – ironing printed and dyed fabric

- FZ/T 64068 – 2019 Oil – and stain – resistant woven adhesive interlining

Adhesion

The property of a material to resist peeling or separation into two or more layers.

- GB/T 26843 – 2011 Determination of carpet backing peel strength

- GB/T 31294 – 2014 Determination of surface layer peel strength of sandwich panels with core materials for wind turbine blades

- FZ/T 80007.1 – 2023 Test method for peel strength of clothing using adhesive interlining

- FZ/T 01085 – 2018 Test method for peel strength of adhesive interlining

- FZ/T 60011 – 2016 Test method for peel strength of composite fabrics

- FZ/T 60039 – 2013 Test method for peel strength of coated fabrics for membrane structures

- FZ/T 80007.1 – 2006 Test method for peel strength of clothing using adhesive interlining

- FZ/T 01010 – 2012 Determination of coating peel strength of coated fabrics

Blocking

Undesired adhesion between the layers of materials in contact with each other.

Peeling strength

The force required to separate the combined layers that make up a fabric.

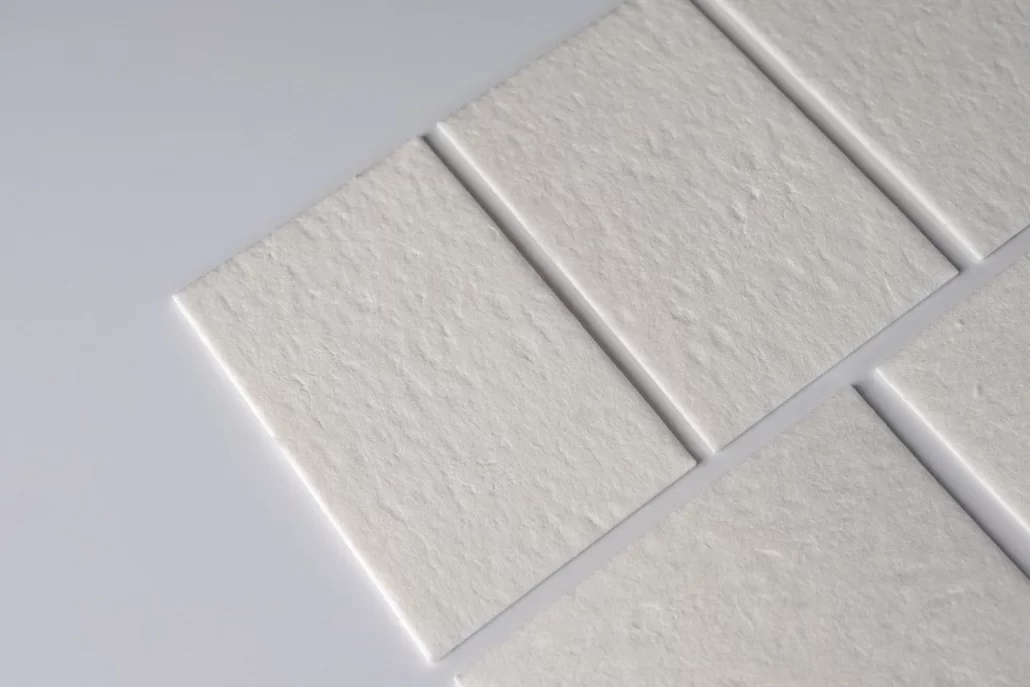

Specifications of Blotter Paper for Absorbent Pads Recommended by Non – woven National Standard GB/T 24218, International Standard ISO 9073, and NWSP Standard

Introducing the specifications of blotter paper recommended by non – woven national standards, international standards, and NWSP standards.

- Ahlstrom 4×4 – inch (100×100 mm) blotter paper

- Model specification: Grade 88, 2000 pieces/box

- Compliance test standards:

- NWSP 070.3.R1

- NWSP 070.7.R2 Nonwoven coverstock Multiple Liquid strike – Through time using simulated urine

- ISO 9073 – 8 – 1998 Textiles – Test methods for non – wovens – part 8: Determination of liquid strike – through time (simulated urine)

- ISO 9073 – 13 – 2006 Textiles – Test methods for nonwovens – part 13: Repeated liquid strike – through time

- GBT 24218.8 – 2010 Textiles – Test methods for non – woven fabrics – Part 8: Determination of liquid penetration time (simulated urine)

- GBT 24218.13 – 2010 Textiles – Test methods for non – woven fabrics – Part 13: Determination of multiple liquid penetration times

- Test purpose: Commonly used for testing the liquid penetration time of hydrophilic non – woven fabrics (non – woven cloth), and it is a specified test consumable by EDANA, such as for testing the performance of the skin – contact layer of diapers.

- Ahlstrom 5×5 – inch (125×125 mm) blotter paper

- Model specification: Grade 632, 8000 pieces/box

- Compliance test standards:

- NWSP 070.8.R1 wetback After Repeated strike – Through Time

- 10.R2 Nonwovens coverstock wetback

- ISO 9073 – 14 – 2007 Textiles – Test methods for nonwovens – part 14: coverstock wetback

- GBT 24218.14 – 2010 Textiles – Test methods for non – woven fabrics – Part 14: Determination of the amount of back – wetting of covering materials

- Test purpose: Commonly used for testing the re – wet back – seepage of hydrophilic non – woven fabrics (non – woven cloth), and it is a specified test consumable by EDANA, such as for testing the performance of the skin – contact layer of diapers.

- Ahlstrom 5.5×12 – inch (140×275 mm) blotter paper

- Model specification: Grade 89, 2500 pieces/box

- Compliance test standards:

- 9.R1 standard Test Method for Nonwoven Run – off

- ISO 9073 – 11 – 2005 Textiles – Test methods for nonwovens – part 11: Run – off

- GBT 24218.11 – 2012 Textiles – Test methods for non – woven fabrics – Part 11: Determination of overflow amount

- Test purpose: Commonly used for testing the overflow amount (slip – seepage amount or slip – off amount) of hydrophilic non – woven fabrics (non – woven cloth), and it is a specified test consumable by EDANA, such as for testing the performance of the skin – contact layer of diapers.

- Ahlstrom 6×9 – inch (150×225 mm) blotter paper

- Model specification: Grade 989 SI, 5000 pieces/

- Ahlstrom 6×9 – inch (150×225 mm) blotter paper

- Model specification: Grade 989 SI, 5000 pieces/box

- Compliance test standards:

- NWSP 080.3.R1 Evaluation of Water Penetration (Spray Impact Test) of Nonwoven Fabrics (for protective apparel and drapes intended for use in health care facilities)

- ISO 9073 – 17 – 2008 Textiles – Test methods for nonwovens – Part: Determination of water penetration (spray impact)

- GBT 24218.17 – 2017 Textiles – Test methods for non – woven fabrics – Part 17: Determination of water impermeability

- AATCC Test Method 42 – 2017 Water Resistance: Impact Penetration Test

- Test purpose: Commonly used for testing the impact water impermeability of water – repellent or waterproof non – woven fabrics (non – woven cloth), such as for testing the performance of medical protective clothing materials.

List of Blotter Papers

We offer a wide range of Ahlstrom blotter papers for various standard test methods such as the following. Papers conform to NDA, EDANA, AATCC and other textile test methods. All papers are kept in stock and readily available.

| Size | Name | Test Method | Paper Grade |

| 100 x 100 mm(4’x4′) | NWSP 70.2 & NWSP 70.7 Strike Through ISO 9073 – 8 & ISO 9072 – 13 | Type Grade 589 | |

| 125×125 mm(5’x5′) | NWSP 70.9 & NWSP 80.10 Re – Wet/Wetback ISO 9073 – 14 | Type Grade 632 | |

| 125 x 125 mm (5 x5′) | Type Grade 989 | ||

| 140×275 mm(5.5 x12) | NWSP80.9 Run – off ISO 9073 – 11 | Type Grade 999 | |

| 150×225 mm(6×9) | NWSP 80.3/AATCC TM42/ AAMI P970/ISO 9073 – 17 Spray Impact | Type Grade 999 | |

| 150×225 mm(6×9′) | AATCC TM42 | Type Grade 330 | |

| 500 x 1000mm (20 x 40′) | AATCC TM35 Rain Tester ISO22958 | Type Grade 230 | |

| 10×10″ | Type Grade 230 | ||

| 6×6 | Type Grade 330 | ||

| 469.90×495.30 mm (18.5°x19.5) | Filter Paper for Agriculture Test | ISO 535/TAPPIT205 | Type Grade 999 |

| 125×125 mm | Filter Paper | Type Grade 240 | |

| 100×100 mm(4×4′) | Filter Paper for Blood Test | Type Grade 270 | |

| 125mm Circle | Filter Paper Circles | Type Grade 54 | |

| 15cm Circle | Filter Paper Circles | Type Grade 631 | |

| 9cm Circle | Filter Paper Circles | Type Grade 617 | |

| 9cm Circle | Filter Paper Circles | Type Grade 950 | |

| 9cm Circle | Filter Paper Circles (NAFC) | Type Grade 961 | |

| Filter Paper Veripood |

Conclusion

Mastering textile property terms and testing methods is fundamental for ensuring fabric performance and quality across various industries. By understanding concepts like air permeability, moisture permeability, and hydrostatic pressure, manufacturers can design high-performance textiles that meet industry standards. Whether you are involved in textile production, research, or simply interested in fabric technology, staying informed about these testing methods will help you make more informed decisions. As textile technology continues to advance, ongoing research and standardized testing will remain pivotal in shaping the future of functional fabrics.

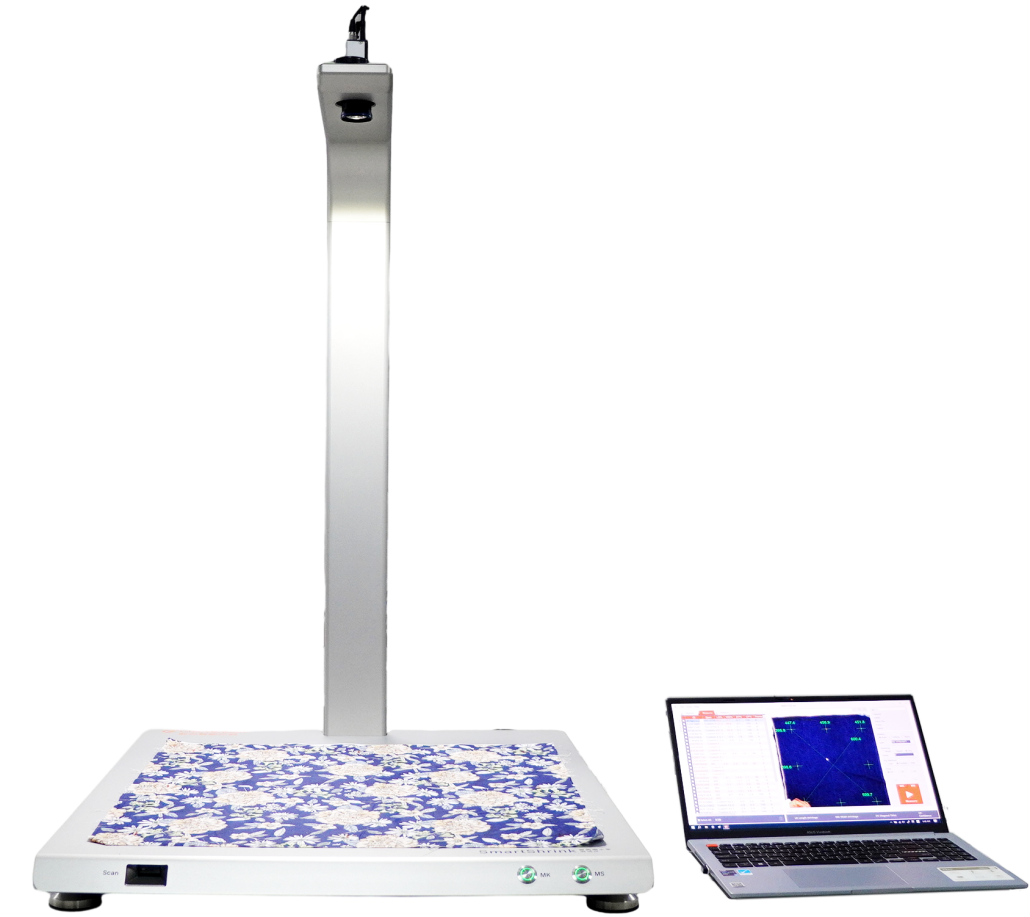

For more information on smart textile testing instruments, or to obtain professional testing solutions, please contact us!

Email: sales@chivention.com

WhatsApp: +86 180 2511 4082

Linkedin: Chiuvention