Customer Success Case: TEXWINCA Knitted Fabric Factory

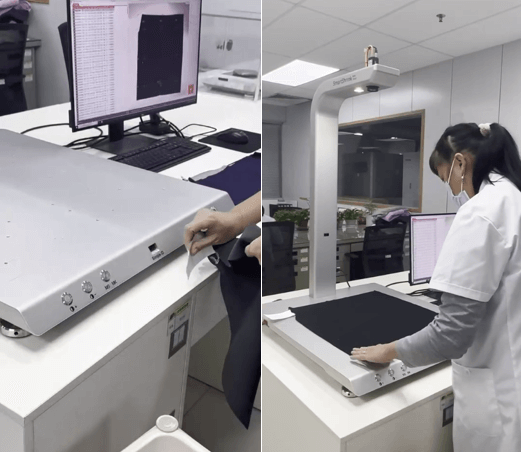

TEXWINCA is a large-scale knitted fabric factory, invested in HongKong in 1992, with an annual production value of nearly $700 million. TEXWINCA needs to do a lot of fabric testing every day, which requires a lot of manual operation, of which the shrinkage rate test is more labor-intensive, and the testing process is complicated, what’s worse, the more the test samples, the more error there is. Therefore, TEXWINCA hopes to have a faster and better solution for shrinkage rate testing.