Introduction to Hydrostatic Head Testing

Hydrostatic head testing is a vital method used to evaluate how well water-resistant or waterproof fabrics can withstand water pressure. This test determines the pressure level at which water begins to penetrate the fabric, which is crucial for applications in outdoor gear, tents, rainwear, and protective coverings.

What Is Hydrostatic Head?

Hydrostatic head is a measure of a fabric’s resistance to water under pressure. In the outdoor industry, it quantifies how waterproof a material is. The higher the hydrostatic head value, the more water pressure the fabric can endure before leaking.

Test Principle

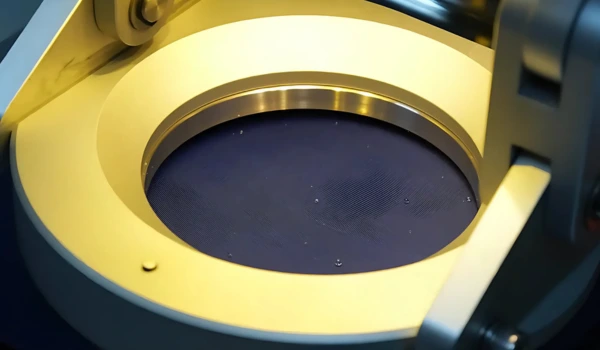

The test involves placing a fabric sample on a hydrostatic head tester. Water pressure is gradually applied from below until water droplets appear on the fabric’s surface. The pressure at which water first seeps through is recorded, typically in millimeters (mm) or kilopascals (kPa).

How the Manometer Works

A manometer filled with water measures the pressure applied. As the water column rises, it creates hydrostatic pressure on the fabric. The height of the water column directly correlates to the pressure. When water finally penetrates the fabric, the corresponding pressure value is recorded as the hydrostatic head.

Hydrostatic Head vs. Water Repellency

While both terms relate to water resistance, they refer to different properties:

| Hydrostatic Head | Water Repellency |

|---|---|

| Measures pressure at which water penetrates through the fabric | Measures how well the fabric’s surface repels water droplets |

| Relates to fabric structure and membrane | Relates to surface finishes like DWR coatings |

| Indicates waterproof performance | Indicates water-shedding ability |

Water-repellent finishes enhance surface resistance but do not necessarily improve the hydrostatic head.

Importance and Applications

Hydrostatic head testing ensures a fabric’s suitability for specific environments. For example:

-

Tents and Ground Sheets: A high hydrostatic head value keeps users dry in wet or muddy terrains.

-

Rainwear: Ensures waterproof protection during downpours.

-

Vehicle Covers: Protects vehicles from rain damage.

-

Outdoor Furniture Covers: Shields materials from long-term water exposure.

Water pressure during real-world use can vary:

-

Sitting on wet ground: ~1,500–2,000 mm

-

Kneeling: ~10,000 mm

Hence, understanding hydrostatic head ratings helps users choose the right product for their needs.

Testing Standards: ISO 811 & AATCC 127

Two primary international standards govern hydrostatic head testing:

ISO 811

-

Used globally, especially in Europe

-

Designed primarily for non-woven fabrics

-

Test applies water pressure using a water column

-

Pressure increased at a constant rate until leakage

AATCC 127

-

The U.S. standard, common in North America

-

Geared towards woven fabrics

-

Uses a 600 mm water column

-

The procedure closely mirrors ISO 811 with minor variations

Both standards employ a hydrostatic head tester and follow nearly identical principles with slight differences in setup and fabric types.

How to Perform the Test (with and without Professional Equipment)

Standard Lab Testing Procedure

-

Condition the fabric sample.

-

Place it securely on the instrument’s head using a clamping system.

-

Gradually increase water pressure via a manometer.

-

Record the pressure when 2–3 droplets appear on the outer surface.

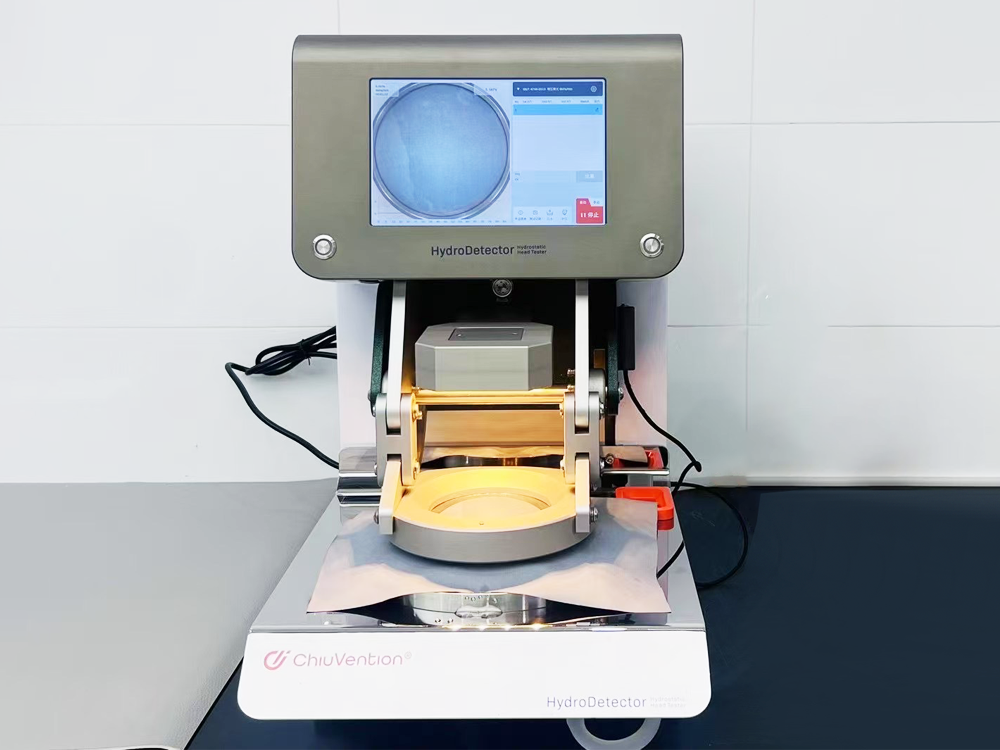

If you choose HydroDetector, the test will become much easier. Just put the sample to the test area and select the hydrostatic head testing standards, then press the test button, all test procedures can be done automatically. Let’s check why HydroDetector can be so powerful:

💧 AI-Powered Water Droplet Recognition

Equipped with HD visual detection and intelligent algorithms, this hydrostatic head tester autonomously identifies the formation of compliant water droplets or rupture indicators. Once detected, the system automatically halts the test and notifies the operator via an app or buzzer. It continuously improves through AI learning and OTA updates, ensuring enhanced precision over time.

🎥 Smart Review with Intelligent Assistance Mode

The system features automatic video recording and playback. Complex or questionable test outcomes can be reviewed efficiently. In case of AI misjudgment, manual correction is supported through intuitive annotation, enhancing overall reliability.

🧩 Adaptive Clamping for Leak-Free Testing

Thanks to an intelligent servo-driven clamping mechanism, the tester adjusts grip strength in real time according to test pressure. This guarantees secure sealing to prevent water leakage while preserving the integrity of delicate samples.

💪 Stable, Servo-Controlled Pressurization

The servo-mechanical pressurization system delivers consistent and controlled water pressure. It prevents sudden bursts or splashing after rupture, contributing to repeatable, reliable hydrostatic head testing results.

⬆️ High-Pressure Testing Capability

Engineered for robust testing, the instrument supports water resistance evaluation up to 600 kPa, with options to customize for even higher pressures. Ideal for heavy-duty or technical material applications.

📱 User-Friendly Smart Touchscreen Interface

Like a smartphone, the intuitive interface lets users monitor test progress, view HD recordings, and export results in various formats. Integrated IoT features allow remote monitoring, report sharing, and LIMS upload—no need for constant on-site supervision.

🔇 No Compressed Air Required

Unlike traditional testers, this unit operates quietly without the need for compressed air. Its modular design also supports fast fixture or clamp swaps for efficient sample transitions.

🌍 Versatile Applications Across Materials

This hydrostatic head testing system suits a variety of materials—textiles, films, papers, geotextiles, construction membranes, and more. Adjustable water column pressure ensures tailored testing for different performance standards.

🇩🇪 German-Inspired Engineering Excellence

Our equipment is co-developed with renowned German industrial designers, ensuring unmatched durability and performance. Built in-house with 100% direct-from-factory pricing—combining aesthetic precision and manufacturing reliability.

DIY Hydrostatic Head Testing

In situations without lab access:

-

Use a transparent cylinder sealed over the fabric.

-

Slowly fill with water while maintaining a watertight seal.

-

Measure the water column height when leakage occurs.

-

Ensure consistent cylinder diameter for repeatable results.

Note: Larger column diameters lower the pressure due to increased surface area, which affects results.

Validity and Limitations

Is Hydrostatic Head a Valid Test?

Yes, if conducted under controlled conditions. Consistency and repeatability depend on:

-

Constant water height

-

Identical column diameter

-

Elimination of external variables

Limitations

-

Does not account for wear and tear: Fabrics may develop pinholes over time (e.g., through folding).

-

Excludes long-term exposure: Some standards measure pressure only for one minute, others for hours.

-

No mechanical force consideration: Real use may involve abrasion, stretching, or pressure points not simulated in the test.

-

Does not assess water flow rate after leakage

Advanced Testing: Simulation and Field Use

Lab Testing

-

Performed under controlled temperature and humidity

-

Produces quick, repeatable, and cost-effective results

-

Ideal for R&D and quality control

Simulative Testing

-

Uses rain towers simulating actual rainfall (e.g., 450 L/m²/h from 10 meters)

-

Water droplets (5 mm diameter) sprayed at 40 km/h from 2,000 nozzles

-

Expensive but highly accurate

Field Testing

-

Involves real-world use cases and long-term exposure

-

Offers best insights but is costly and time-intensive

Understanding Test Reports

A proper hydrostatic head test report includes:

-

Average value from at least five tests

-

Time and pressure at leakage

-

Test conditions (temperature, humidity)

-

Material type and structure

This data helps manufacturers and buyers predict fabric performance in real scenarios.

Choosing the Right Waterproof Fabric

Ask yourself: What will you use the fabric for?

Then consider:

-

Hydrostatic head rating (measured in mm)

-

Breathability

Simple Breathability Test

-

Boil water in a mug

-

Cover it with the waterproof fabric

-

Place a clear beaker on top

-

If condensation appears, the fabric is breathable and waterproof

-

If not, it may be waterproof but not breathable

Common Testing Issues and Solutions

| Issue | Solution |

|---|---|

| Non-standard water (salty or hot) | Use distilled water at room temperature |

| Air pockets under fabric | Place fabric smoothly, roll from one side to avoid bubbles |

| Poor sealing | Use rubber seals and check clamping before testing |

| Inaccurate results | Perform machine calibration regularly with standard materials |

Ensuring Test Accuracy

Calibration and Maintenance

-

Clean the tester regularly

-

Check and adjust water level

-

Calibrate the pressure gauge

-

Run control tests with known standard samples

Standardized Procedures

-

Follow ISO or AATCC guidelines

-

Use consistent environmental conditions

-

Train technicians for repeatable and accurate results

Conclusion

Hydrostatic head testing is a critical measure of fabric waterproofness, especially in outdoor and technical applications. ISO 811 and AATCC 127 are widely accepted international standards for this test.

The key to meaningful results lies in proper calibration, correct setup, and following standard procedures. Understanding test results helps manufacturers and consumers select the right materials for tents, rainwear, and protective gear.

FAQs

What does the hydrostatic head of a fabric mean?

It indicates how much water pressure a fabric can resist before water starts seeping through.

Is the hydrostatic head the same as water repellency?

No. Hydrostatic head measures water penetration resistance, while water repellency checks if water beads off the surface.

What is a good hydrostatic head rating?

-

1,500 mm: Minimum for waterproof classification

-

10,000 mm+: Ideal for extreme conditions (e.g., mountaineering tents)

Can I test the hydrostatic head at home?

Yes, with a water-filled cylinder and a watertight seal, you can perform a basic DIY version of the test.