Air permeability is one of the fundamental requirements for comfort in clothing. Since the perception of air permeability is more subjective than rational, how can we effectively evaluate and test it?

Introduction

Have you ever wondered what makes your favorite sportswear so breathable or how medical masks manage to be both protective and comfortable? The answer lies in air permeability testing, a fascinating and essential process used across various industries. This blog invites you on a journey to discover the intricacies of air permeability testing. From its crucial applications in textiles to the different methods and standards like ISO 9073-15 and ASTM D737, we’ll uncover how this testing ensures materials perform at their best. Whether it’s selecting and conditioning samples or adjusting airflow and interpreting results, we’ve got you covered to ensure your fabrics excel in quality and performance.

Application of Air Permeability Testing

Air Permeability Testing in the Textile Industry

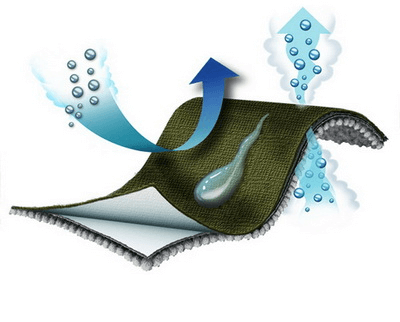

Air permeability is a crucial factor affecting fabric performance. The comfort of clothing, decorative fabrics, and other textiles is closely related to their air permeability. Air permeability testing has wide applications in the textile industry, including the following areas:

Clothing Industry: Air permeability testing is a key indicator of textile comfort. It is especially important in the design of outdoor sportswear and sports shoes, where air permeability tests verify whether these products provide good ventilation, achieve moisture absorption and perspiration, and keep the wearer dry and comfortable.

Household Textiles: For products like bedding, curtains, and furniture covers, air permeability tests can determine the air permeability rate of these items, affecting their comfort and suitability.

Medical Clothing: Medical textiles such as surgical gowns and masks require good air permeability to ensure that healthcare workers remain comfortable during long working hours. Through air permeability testing, the gas exchange performance of these products can be determined to prevent bacterial and viral infections.

Sports Gear: Some sports gear, such as sports shoes and caps, also undergo air permeability testing to ensure their air circulation performance.

Air Permeability Testing in Other Industries

Automotive Interior Materials: Measures the air permeability and air resistance of automotive interior materials (e.g., polyurethane, PVC, leather, textiles, non-woven fabrics) using air permeability test apparatus.

Building Materials: Measures the air permeability of building materials (e.g., stone, concrete) to assess their impact on indoor air quality according to air permeability test standards.

Medical Products: Medical products like surgical gowns and masks need a certain degree of air permeability to ensure comfort and efficiency, evaluated through air permeability testing.

Packaging Materials: Many special packaging materials (e.g., preservation packaging) need to have certain air permeability to ensure the quality of the contents, assessed using air permeability units.

Electronics: Some components of electronic products need good air permeability to ensure the proper functioning of electronic devices, tested through air permeability test for fabric.

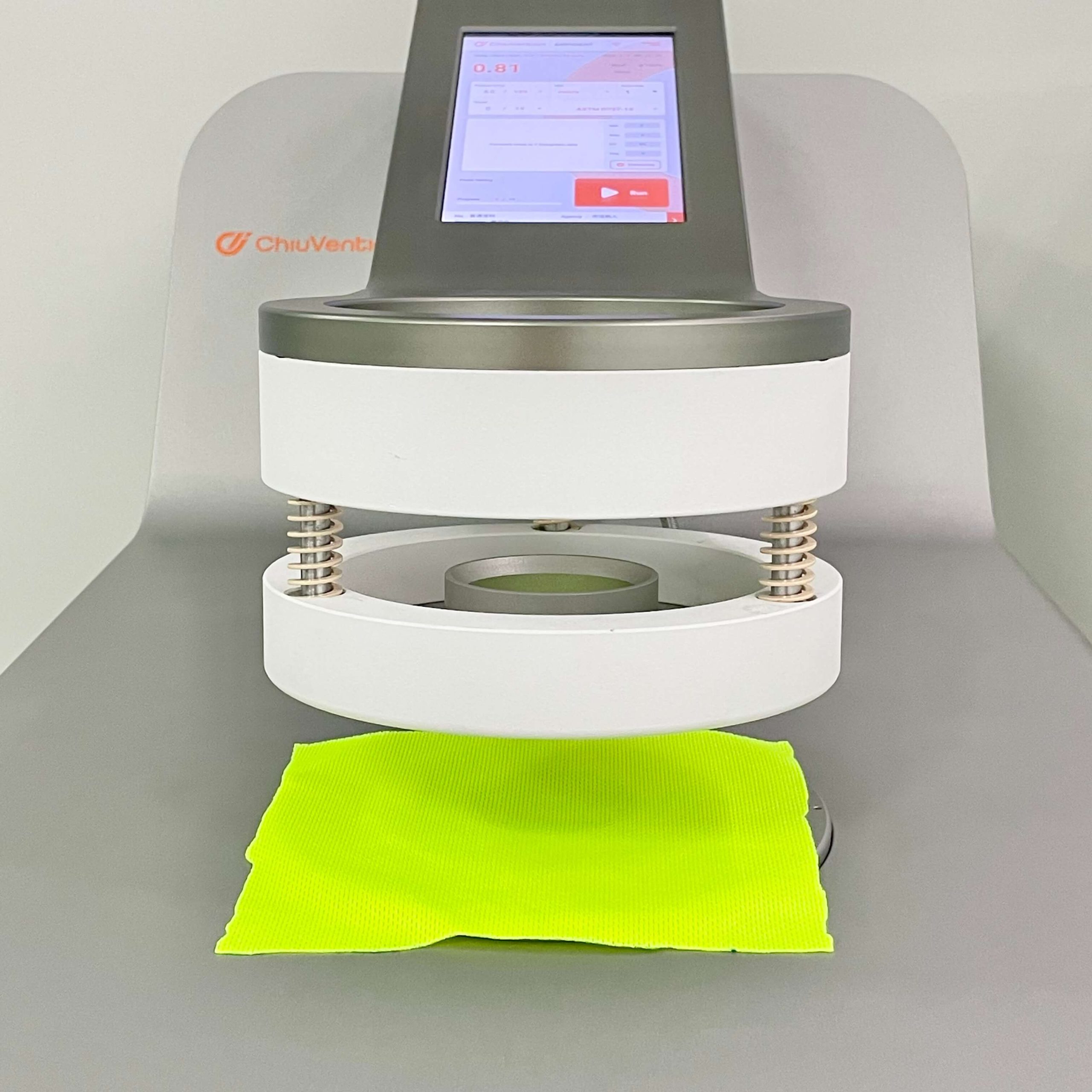

Air Permeability Testing Machine

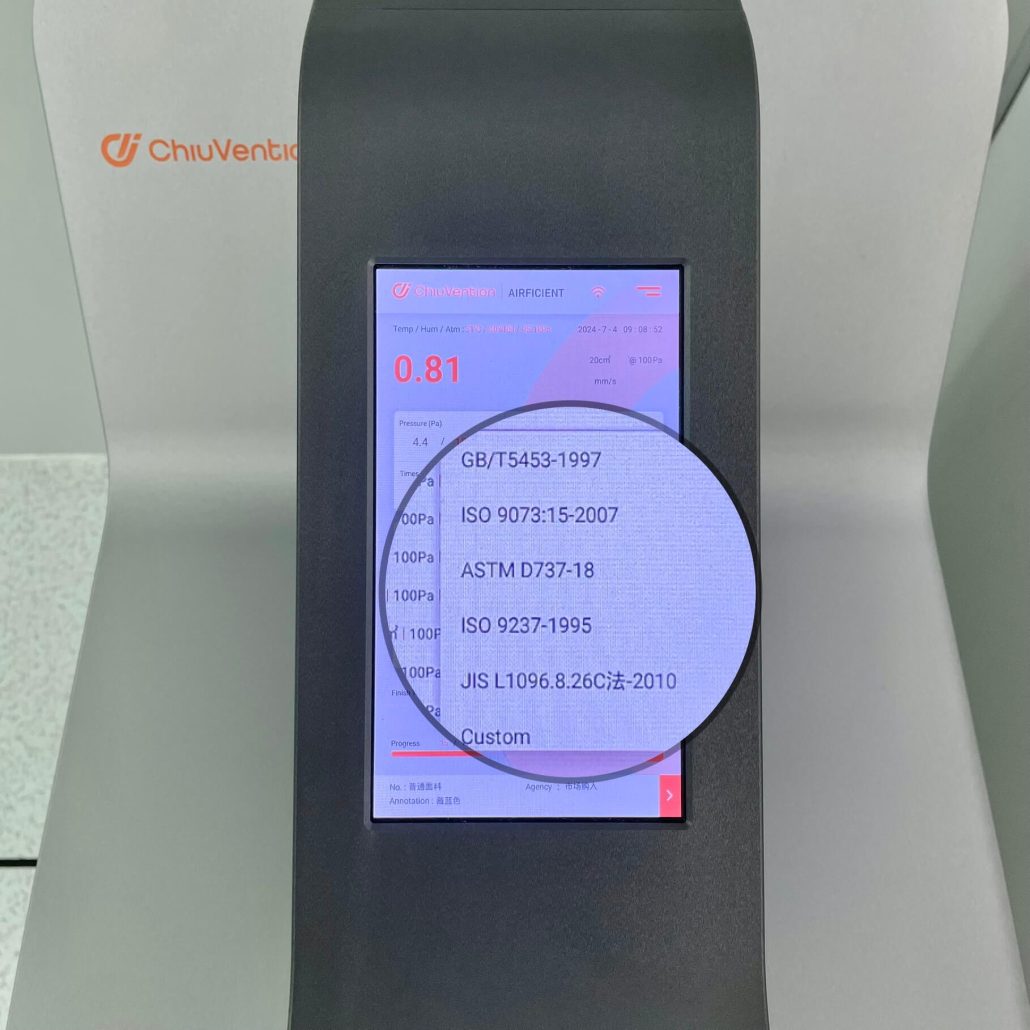

AirFicient Air Permeability Tester can be used for many textiles, including technical fabrics, non-woven fabrics, and other breathable products, such as sponges, paper, and other materials for air permeability testing. This AirFicient air permeability tester for textiles complies with multiple standards, including GB/T 5453, ISO 9237, ISO 9073:15, JIS L1096 Item 8.26 Method C, BS 3424-16, BS 6F 100 3.1, NWSP 070.1.RO(15), and GB/T 24218.15.

Features:

- Ease of Use: Testing is simple and quick. Users can select the test standard and measurement units directly on the operation screen.

- Automatic Identification: The device automatically identifies different ranges of the test fixture head.

- Automated Testing: Start testing directly, and the device automatically generates the test results.

For a step-by-step guide on how to operate the AirFicient air permeability tester for fabric, please click on the video link. For more information, contact us at [email protected] or WhatsApp: +86 180 2511 4082.

Different Air Permeability Testing Methods

There are numerous standards and methods for measuring air permeability tests of fabric. Below is a comparison of the commonly used air permeability test standards both domestically and internationally.

ISO 9073-15

- Features:Suitable for measuring the air permeability of nonwoven materials.

- Application Range:Used for testing the air permeability of nonwoven materials, such as fiberboards and filter materials.

- Test Principle:Uses the air flow method to measure the flow of gas through the sample to evaluate air permeability of fabrics.

- Test Equipment:Air permeability testing machine including an air source, test fixtures, and a flow meter.

GB/T 5453 and GB/T 24218.15

- Features:Suitable for measuring the air tightness and air permeability of textiles.

- Application Range:Used to evaluate the air permeability of textiles, including fabrics and clothing.

- Test Principle:Uses the air flow method or the water vapor transmission method to measure the rate of gas or water vapor passing through the sample.

- Test Equipment:Depending on the test method, different permeability meters may be needed, such as an air permeability tester for the air flow method, while a humidity control equipment for the water vapor transmission method.

BS 3424-16 and BS 6F 100 3.13

- Features:Suitable for measuring the air permeability of fabrics.

- Application Range:Used to evaluate the air permeability of fabrics, including textiles and clothing.

- Test Principle:Uses the air flow method or the water vapor transmission method to measure the rate of gas or water vapor passing through the sample.

- Test Equipment:Depending on the test method, different permeability meters may be needed, such as an air permeability tester for the air flow method, while a humidity control equipment for the water vapor transmission method.

ASTM D737

- Features:Suitable for measuring the air permeability of fabrics.

- Application Range:Primarily used to evaluate the air permeability of fabrics.

- Test Principle:Uses the air flow method to measure the flow of gas through the sample to evaluate air permeability.

- Test Equipment:Air permeability test machine including an air source, test fixtures, and a flow meter.

JIS L1096 Item 8.26 Method C

- Features:Measures air permeability by determining the air flow through a specified area.

- Application Range:Widely used in the Japanese textile industry.

- Test Principle:Uses the air flow method to measure the air permeability of fabrics.

- Test Equipment:Air permeability test machine including air source, test fixtures, and flow meter components.

Need a free quote on air permeability tester price now? please click the picture below!

Main Differences and Comparisons

These air permeability test standard are issued by different countries or organizations, such as ISO, GB, BS, ASTM, and JIS. Each standard may apply to different types of materials or products, such as nonwoven materials and textiles. Different standards may use different test principles, such as the air flow method or the water vapor transmission method. Although most standards use similar test principles, the specific test equipment may vary depending on the requirements of the standard.

Among these, ISO 9237 and ASTM D737 are the most widely applied air permeability test standards.

GB/T 5453-1997 is applicable to various textile fabrics, including industrial fabrics, nonwoven fabrics, and other breathable textile products. During testing, different pressure drops are used to distinguish between clothing fabrics and industrial fabrics, with a pressure drop of 100Pa for clothing fabrics and 200Pa for industrial fabrics. In the GB/T 5453-1985 “Test Method for Air Permeability of Fabrics,” air permeability is measured by the volume of air passing through a unit area of fabric under a specified pressure difference per unit time. The revised standard GB/T 5453-1997 uses the air permeability rate, which is the rate of airflow passing vertically through the sample under specified conditions of sample area, pressure drop, and time, to indicate fabric air permeability.

ASTM D737 differs from the above standards in terms of application scope, temperature and humidity conditions, test area, and pressure difference. Considering the actual situation of import and export textile trade, it is proposed to compare the specific conditions of temperature and humidity, test area, and pressure difference of ISO 9237 and ASTM D737 using different samples. This will help establish an industry standard suitable for import and export trade.

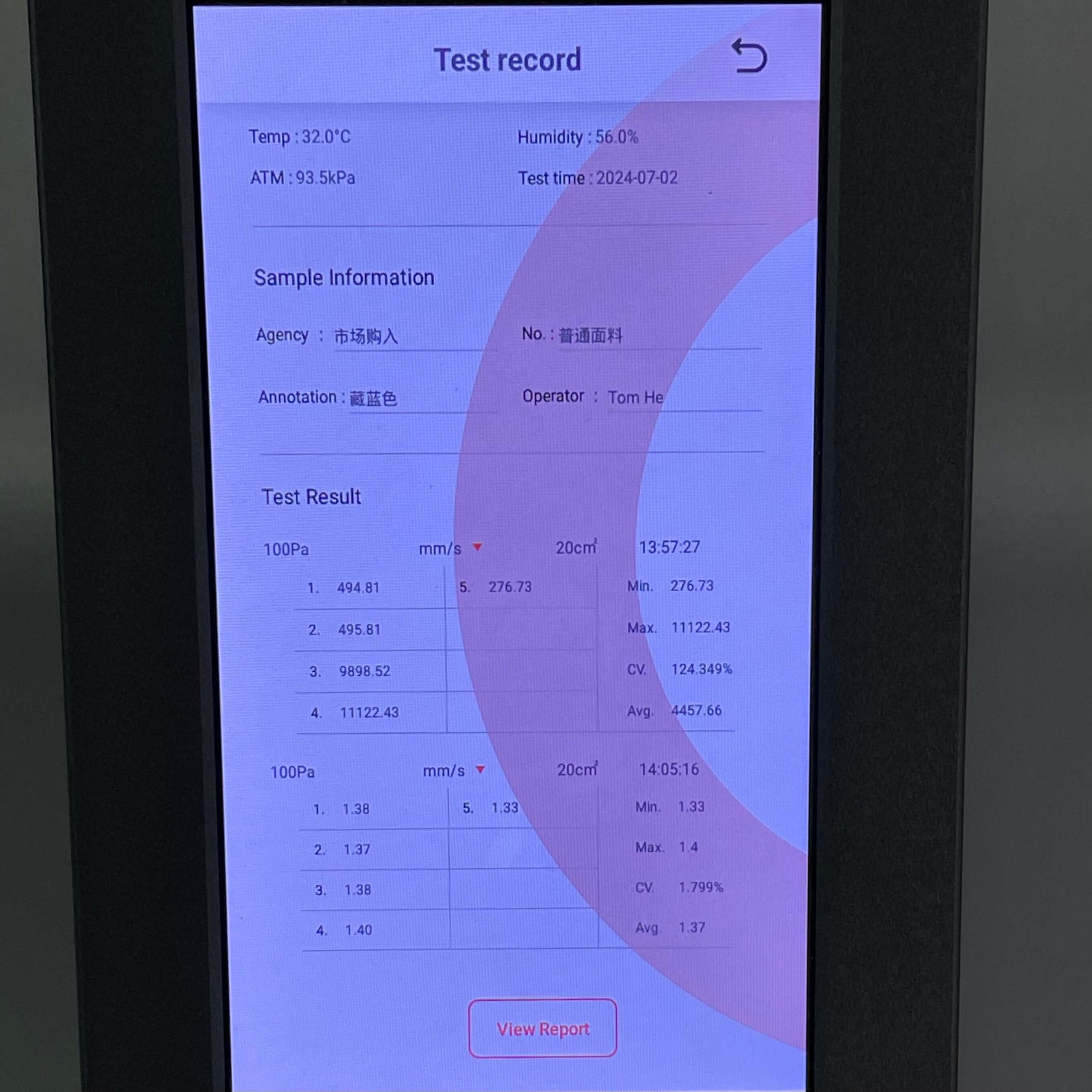

Testing Procedures: A Step-by-Step Instruction on GBT 24218.15

Sample Selection

Determine the sampling method based on the product standard or through consultation with relevant parties. For testing equipment that can directly test large nonwoven fabric samples, randomly select at least five locations on the large nonwoven fabric as samples for testing. For equipment that cannot test large samples, use a cutting die or template to cut at least five samples of 100mm x 100mm size.

Conditioning the Samples

Place the samples in a standard atmospheric environment as specified by GB/T 6529 to reach equilibrium. This step ensures that the samples are conditioned and moisture-balanced according to the standard.

Handling the Samples

Hold the edges of the samples to avoid altering the natural state of the nonwoven fabric’s test area.

Positioning the Samples

Place the sample on the testing head and use a clamping system to secure the sample, preventing any distortion or edge leakage of gas during the test. If there is a difference in air permeability between the two sides of the sample, note the tested side in the test report. For coated samples, place the coated side down (toward the lower pressure side) to prevent edge gas leakage.

Adjusting the Airflow

Turn on the vacuum pump and adjust the airflow rate until the desired pressure differential is achieved, which could be 100Pa, 125Pa, or 200Pa. On some modern instruments, the test pressure values are digitally preselected, and the pressure differential across the measurement orifice is displayed in the selected unit, making it convenient for direct reading.

Reading the Air Permeability Value

If using a pressure gauge, wait until the required pressure value stabilizes before reading the air permeability value. The value is expressed in liters per square centimeter per second [L/(cm²·s)].

By following the above detailed steps, you can ensure accurate and consistent air permeability testing results.

Comparison of Air Permeability Test Results

The results of fabric air permeability are closely related to the testing methods used. Among the test results obtained by four different testing methods, namely, ISO 9237, GB/T 5453, ASTM D 737 and JIS L 1096: the air permeability tested by GB/T 5453 and ISO 9237 are the same; the air permeability tested by GB/T 5453 (ISO 9237) is the smallest; the air permeability tested by JIS L1096 is the largest; and the air permeability tested by ASTMD737 is in the middle. The air permeability tested by ASTMD 737 is in the middle. In the case of the same test area, the air permeability increases with the rise of the pressure drop, which is directly proportional to the pressure drop incremental times. In summary, companies must choose the appropriate testing method based on the characteristics of their products to accurately evaluate the air permeability of the fabric.

Factors Affecting the Air Permeability of Fabrics

Fabric Factors

Fiber and Yarn Structure

When the linear density of warp and weft yarns and the warp yarn arrangement density are the same, fabrics made from shaped fibers have better air permeability than those made from round cross-sectional fibers. Fabrics with coarser single fibers have better air permeability compared to those with finer single fibers.

Fabric Weave Structure

Under the same arrangement density and tightness, the air permeability strength in ascending order is: plain weave < twill weave < satin weave < porous structure.

Post-Finishing Processing

Dyeing and finishing processes can tighten the fabric structure, reducing air permeability. Weight reduction treatments can thin the fibers, increase the gaps between fibers and yarns, and consequently increase air permeability.

Environmental Factors

Relative Humidity at a Constant Temperature

Air permeability decreases with increasing relative humidity. When the fabric absorbs moisture, the fibers swell, the pores shrink, reducing the internal gaps and blocking pores, which leads to decreased air permeability.

Temperature at a Constant Relative Humidity

Air permeability increases with rising environmental temperature. Increased thermal motion of gas molecules enhances their diffusion capacity.

Pressure Changes at Constant Temperature and Relative Humidity

Changes in the air pressure (P) on both sides of the fabric can affect the measured flow rate, and the impact is non-linear.

Understanding these factors is crucial for accurately assessing and controlling the air permeability of fabrics in various applications.

Conclusion

Mastering air permeability testing is essential for anyone involved in the development and quality assurance of materials. By understanding the different methods and standards, as well as the factors that affect air permeability, you can ensure your products meet the highest standards of comfort and functionality. Whether you’re in the textile industry or another field that relies on breathable materials, leveraging these insights will help you enhance your product offerings.