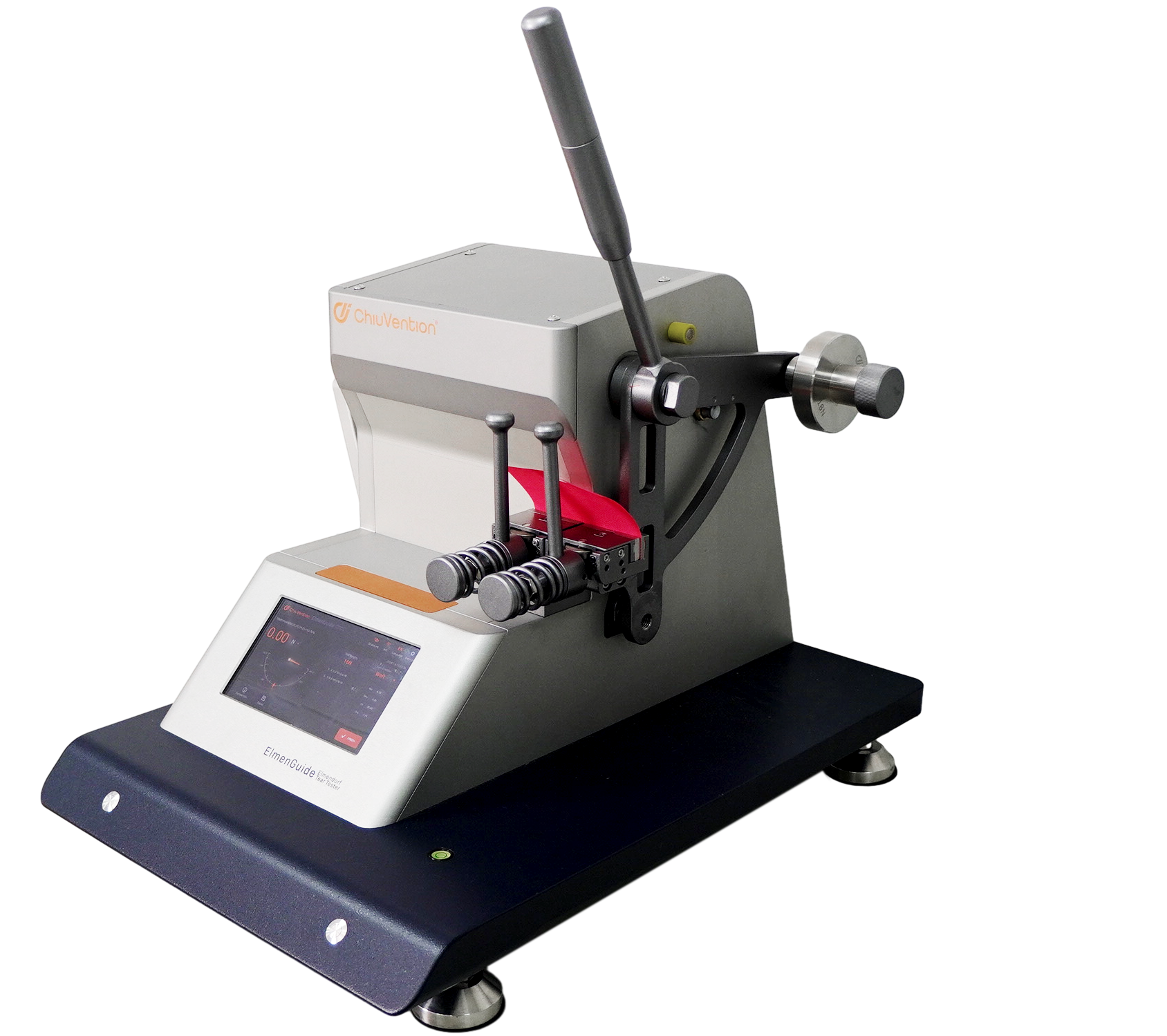

The innovative balance pendulum plate design achieves a higher level of testing accuracy.

The pendulum arm of the Tearing Strength Tester is specially designed. Its center of gravity is at the center of its rotation when no weights are attached. This leads to higher accuracy. It also makes the Elmendorf Tear Strength Test more reliable.

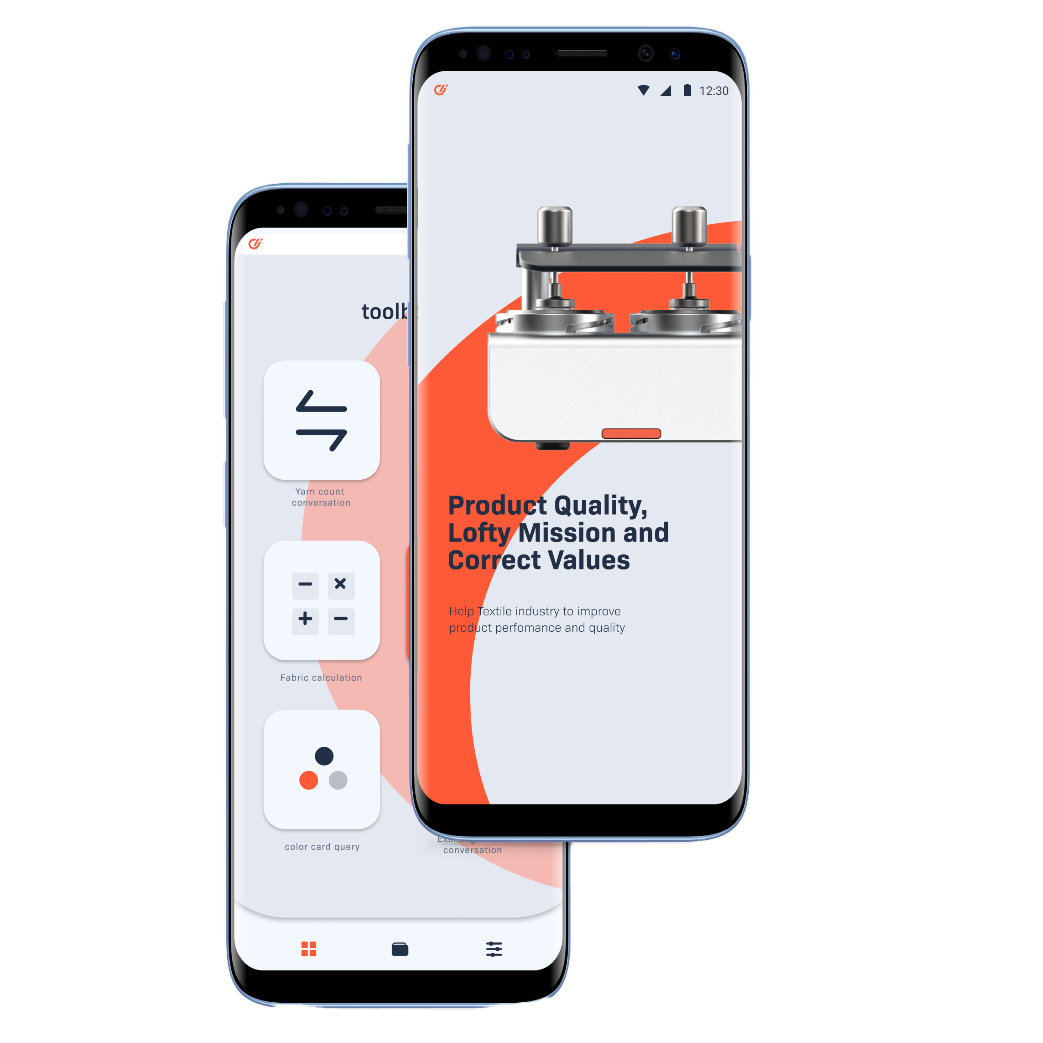

A smart instrument with IoT technology

The Tearing Strength Tester is connected via IoT to the SmarTexLab APP in the phone/PC. And the app can connect to ERP/LIMS via an API. Or, this Elmendorf Tear Tester can connect directly to ERP/LIMS. That system has test orders and sample information. Then, our tear strength tester can start tests and record sample info, the test process, and results.

The system will then summarize these into an Elmendorf Test report. You can send the report to SmarTexLab or ERP/LIMS. And relevant parties can view the report in real-time.

In SmarTexLab, you can set up programs to operate the Tear Strength Tester and chat with ChiuVention service staff for quick support. The customer will receive reminders for the Elmendorf Tearing Tester. It needs calibration, maintenance, and new consumables. Regular OTA remote upgrades are available.

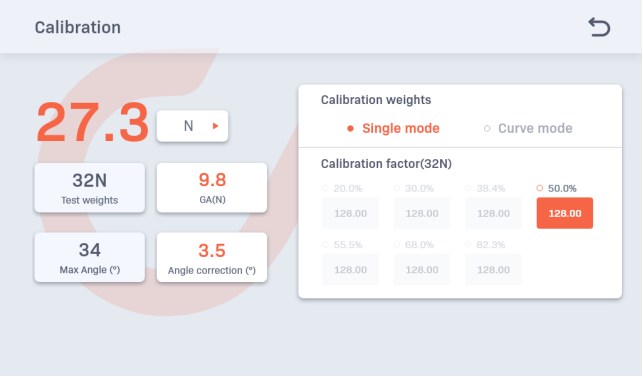

Self-developed calibration system for more reliable testing

Multiple calibration points for each test range to ensure stable and reliable testing.

Automatic recognition of weights

The machine can automatically recognize the hanging weights and adjust the matching range automatically.

Humanized design, for more safety.

The switch of this tearing strength tester has 2 buttons. It prevents accidents and is easier for testers.

Precise manufacturing and stable operation

The Tester’s fixture rotates with ease. It loses a few empty pendulums. You can choose many measurement units (N, CN, gf, bf). Also, the ElmGuide Elmendorf Tearing Tester has a precise appearance design. It has an aluminum alloy hard oxidation surface. This surface is sleek, tough, and easy to clean. The trapezoidal chassis is more stable. Our tear-strength tester has a seven-inch color touchscreen. It is simple and easy to use.

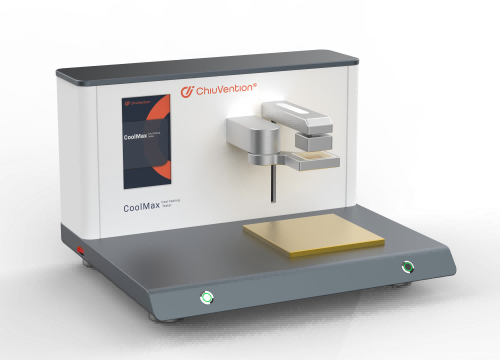

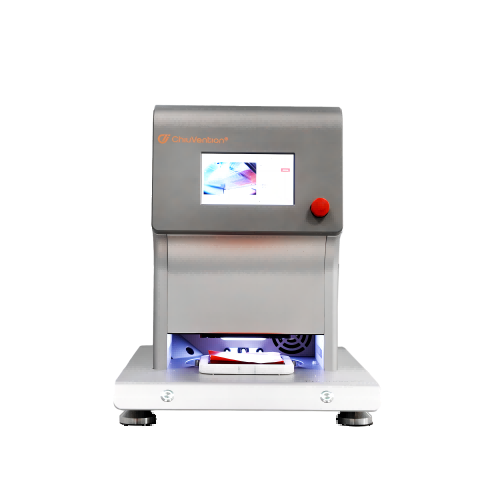

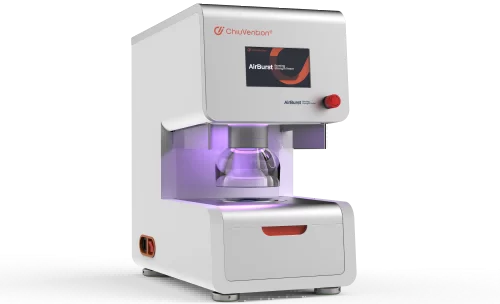

Designed in Germany, quality is our life.

All our textile testing instruments are developed in-house and in cooperation with a team of renowned German industrial designers, which makes our instruments of outstanding quality. 100% source factory and factory price.

Application Examples of ElmenGuide Elmendorf Tear Tester

Leather

Plastic Film

Nylon Fabric

Paper Or Packaging Material

Customer Feedback

“We have been to ChiuVention three times and brought samples for tear testing. The results matched our testing center’s. So, we chose this ElmenGuide tear tester as it is very reliable .”

“I learned that ChiuVention has invested a lot of resources in the field of intelligent testing, and the ElmenGuide we purchased is equipped with IoT, so test data can be seen on the smartphone or computer, which is very efficient for us to do test data management.”

Elmendorf Tearing Test belongs to the pendulum test method, which is to test the tear resistance of the fabric, and in the normal fabric test, we also need to do a fabric strength test or the fabric tensile test, then we often use SmartPull Tensile Tester.

The Specification of Elmendorf Tearing Tester

Load range 8N, 16N, 32N, 64N, 128N

Testing accuracy ≤±0.2%F·S

Tear length 43mm

Automatic incision length 20±0.2mm

Sample size 100×75 mm

Standard Accessories of Elmendorf Tearing Tester

Fuse 2 pcs

Sample cutter 1 pc, 100mm*75mm

Test weight A 1 pc, 8N

Test weight B 1 pc, 16N

Test weight C 1 pc, 32N

Test weight D 1 pc, 64N

Test weight E 2pcs, 128N

Test weight F (optional) 2pcs, 256N

Calibration weight a 1 pc, 8C

Calibration weight b 1 pc, 16C

Calibration weight c 1 pc, 32C

Calibration weight d 1 pc, 64C

Calibration weight e 1 pc, 128C

Calibration weight f 1 pc, 256C

Power

220V 50/60Hz Other voltages require an external transformer

Weight

70kg

Dimension

580*420*600 mm (D*W*H)

Standard

ASTM D1424 BS ISO 13937-1 GB/T 3917.1 ISO 4674-2

ChiuVention provides more smart textile testing equipment for you. Contact us for details about textile testing machines.

OUR BROCHURE

FLYER

Frequently Asked Questions of the Elmendorf Tear Tester

The Tear Tester is a specialized instrument designed to measure the tearing strength of paper and paperboard. By evaluating a material’s resistance to ripping, this test provides essential data for industries focused on paper, packaging, and high-quality material handling. That device determines the force required to initiate and propagate a tear using a precise incision. This assessment offers valuable insights into the material’s durability and suitability for various applications, helping manufacturers optimize product performance and reliability.

Tearing strength plays a vital role in the paper and packaging industry, directly impacting the performance and durability of materials. It is especially important during handling, transportation, and everyday use. Products such as packaging materials, bags, and paper goods must be designed to resist tearing to withstand real-world stresses effectively. By accurately measuring tear strength, manufacturers can make informed decisions about material selection and design improvements. This, in turn, enhances product quality, boosts reliability, and ensures better performance across various applications.

Key Differences

Type of Stress:

Tear Test: Focuses on the material’s behavior under tearing stress.

Tensile Test: Focuses on the material’s behavior under uniaxial tensile stress.

Specimen Preparation:

Tear Test: involves notching or pre-cutting the sample.

Tensile Test: Uses standardized specimens without intentional flaws.

Outcomes:

Tear Test: Measures tear strength or resistance to tearing.

Tensile Test: Measures many mechanical properties, including tensile strength, yield strength, and elongation.

Relevance:

The Tear Test is more relevant for materials that tear easily. It is critical for materials where tears spread.

Tensile Test provides a broad view of material behavior under tension. It is useful for many materials.

In summary, both tests evaluate material properties, but they serve different purposes. The tear test specifically measures a material’s resistance to tearing, making it essential for quality control and material selection in products where tearing is a critical failure mode, such as packaging materials, clothing, and elastomers. On the other hand, the tensile test provides a more comprehensive analysis. Tensile test plays a key role in material science and engineering by assessing a material’s strength and deformation characteristics. Commonly used for metals, polymers, ceramics, and composites, the tensile test offers valuable insights into a material’s tensile behavior and overall structural suitability. You can click to learn more about fabric tensile testers.

The Tearing Strength Tester features a modern, stable pendulum plate designed to enhance testing accuracy. It’s specially engineered pendulum arm ensures that the center of gravity aligns precisely with the rotation center, eliminating the need for additional weights. This advanced design plays a crucial role in reducing bias and imbalance within the test apparatus. By maintaining exceptional stability, the Elmendorf Tearing Tester provides a reliable foundation for measuring tear resistance, delivering precise and consistent strength measurements.

Aligning the center of gravity with the rotation center is crucial for ensuring greater accuracy and reliability in tear resistance testing. This design minimizes external influences on the pendulum’s motion, reducing the likelihood of errors in test results. The well-balanced setup enhances consistency across different testing conditions, allowing for more precise and repeatable measurements. As a result, users can have greater confidence in their tearing strength data, making the ElmenGuide Tearing Strength Tester an essential tool for both quality control and research applications.

Load Range

The Tearing Strength Tester offers a highly adaptable load range, with options from 8N to 128N. This flexibility allows users to test a wide variety of materials, from lightweight papers to robust packaging materials. By selecting the appropriate load setting, users can achieve precise and targeted results tailored to their specific testing needs.

Testing Accuracy

Accuracy is at the core of the ElmenGuide Elmendorf Tearing Tester, ensuring highly precise measurements with a testing accuracy of ≤±0.2%F•S. This level of precision provides manufacturers and researchers with reliable data, enhancing confidence in tearing strength assessments. Consistent and dependable results make this instrument an invaluable asset in quality control processes, where precision is essential.

Standardized Testing Parameters

The Elmendorf Tearing Tester adheres to internationally recognized standards, including ASTM D1424, BS ISO 13937-1, GB/T 3917.1, and ISO 4674-2. Compliance with these industry benchmarks ensures that test results are accurate, repeatable, and comparable across different laboratories and testing facilities. By following standardized testing parameters, the instrument promotes consistency and reliability in tear strength evaluations.

Thoughtful Design

The tester is designed with precision in mind, featuring a tear length of 43 mm and an incision cut of 20 ± 0.2 mm. These carefully calibrated specifications create a controlled testing environment that accurately reflects the material’s tear strength. Additionally, the sample size of 100 × 75 mm ensures that a significant portion of the fabric or material is tested, providing comprehensive insights into its durability and resistance to tearing.

The Elmendorf Tester delivers precise performance and stable operation through a combination of advanced design features.

Its fixture is engineered for smooth and flexible rotation, reducing the impact of an empty pendulum during testing. This thoughtful design ensures ease of use while maintaining accuracy and consistency in tear strength measurements. Additionally, the trapezoidal chassis enhances overall stability, providing a solid foundation for reliable tear resistance testing.

The Tearing Strength Tester provides multiple units of measurement, allowing users to select the most suitable option for their testing needs.

Those available units include N (Newtons), cN (centinewtons), gf (gram-force), and cp (standard point). This versatility enables users to align measurements with industry standards or customize them for specific requirements. As a result, the Elmendorf Tearing Strength Tester is well-suited for a wide range of applications across various industries.

Want to know more about the Elmendorf tearing strength test? Welcome to our blog on fabric rear resistance tests.

Repeatability and Reproducibility: The results measured with the ElmenGuide Elmendorf Tearing Strength Tester are highly reproducible, ensuring consistent results from batch to batch and sample to sample.

Accurate Measurement of Tear Strength: The ElmenGuide Tear Resistance Tester accurately measures the point at which a fabric breaks when a tearing force is applied, as well as the force required during the tearing process, ensuring authentic results.

Suitable for different types of fabrics: Fabric manufacturers produce a wide range of fabrics, from lightweight knitted fabrics to heavy industrial fabrics, and the ElmenGuide Tear Resistance Tester can be applied to a wide range of thicknesses and types of textiles, ensuring that the test method is flexible and adaptable.

Automatic data storage and analysis: the Tear Resistance Tester can automatically save, export, and analyze the test data to help manufacturers track quality and trace problems, which is very important for optimizing production and quality control.

Data traceability: The Tear Resistance Tester supports saving detailed test records, making it easy to check past test data at any time, and facilitating the tracing of production links when problems occur.

Cost-effective: The Tear Resistance Tester has good performance, durability, accurate test results, and a very competitive price, and is currently hot-selling in 42 countries and regions around the world.

GET A QUOTE

The Elmendorf tear tester measures the tear resistance of materials. People use it on paper, textiles, and plastics. The principle behind its operation involves the following steps:

Sample Preparation and Clamping:

We prepare a pre-cut sample of the material according to standardized dimensions. Jaws lock onto the sample, holding it firmly in place. One jaw is stationary, and the other is attached to a pendulum.

Pendulum Release:

The pendulum is lifted to a specific height, providing it with a known potential energy. The pendulum is then released. It swings down by gravity.

Tearing Action:

As the pendulum swings, it tears through the pre-cut portion of the sample. The energy required to tear the sample is absorbed by the material as the pendulum continues its arc.

Energy Measurement:

The pendulum’s remaining energy after tearing the sample is shown. It is shown by the height to which it rises on the opposite side of its arc. We calculate the difference in the pendulum’s potential energy. It is before and after tearing the sample. This difference corresponds to the energy absorbed by the sample during the tear.

Reading the result:

The device has a scale or digital readout. It shows the tear strength of the sample. The tear resistance is usually measured in units such as millinewtons (mN) or gram-force (gf).

The Elmendorf tear tester’s key principle is to turn stored energy into tearing work. The tester measures the energy lost during this process. This lets them quantify the tear resistance. It provides valuable information about the material’s durability and performance.

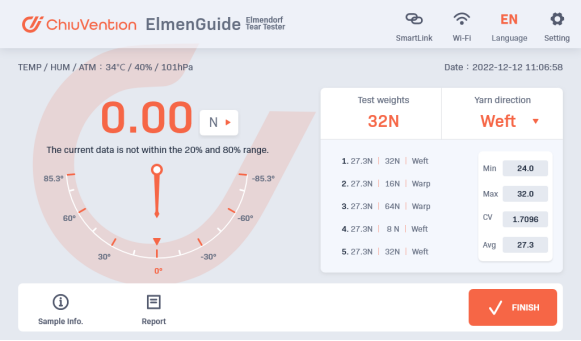

The Home page shows up when the instrument is powered on and the Main menu follows after the startup is completed.

In the main menu, you can bind IOT users. You can set local network connections and switch languages. You can set system settings and also see the measurement value and current angle. You can see the current use of test weights and the tear yarn direction selection. You can also generate a data report.

Menu:

Unit switch. Click the unit switch key in the pop-up box to choose N, cN, or gF. The selected unit is automatically converted.

Test weight switching. Put the proper test weight in the assembly position. The system will then recognize its range. On the right side, the scale’s data is shown in the history list.

Yarn direction selection.

Click the yarn key and in the pop-up box, select either warp or weft yarn as the tear direction. Yarn direction selection will refer to the actual test sample. The history list on the right side will show the test records of the yarn direction under this range.

A history list box showing the records of test results under the current conditions. In this box, we count real-time historical list data into the max, min, CV, and average. Also, the stats will update automatically when the list data changes. You can also delete one at a time. Click the data and drag to the left, the delete key appears. Click the key for data delete.

Sample information setting.

Click this key to jump to the Sample Parameters screen. There, you can set the test facility, tester, sample type, and sample info. All the information will be added to the table header of the report.

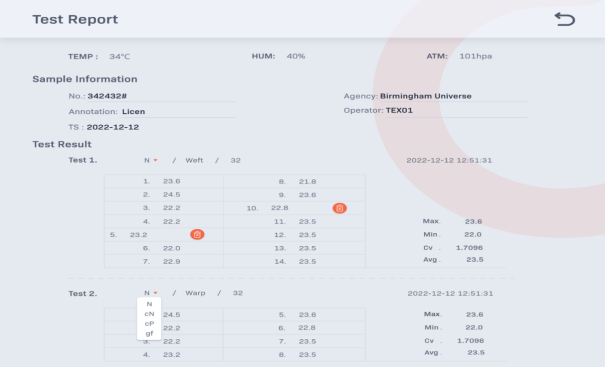

Report review. Click the Report key to the Report List screen where the records kept by the device test are shown. The sample information and the report are in the report column. Click the report column to see the certain detailed information screen. There, you can switch units, modify report sample info, and delete test records.

System Setting

Click this key to open the settings interface. Here you can change the display mode and login password. You can also delete and change IOT users. You can update the software and view the manufacturer’s information.

Setting

Finish. Click this key, and the data of the current list box is added to a new report, and then the data of the history box is cleared. Check the detailed data records in the report list.

Test weights: 8N, 16N, 32N, 64N, and 128N. Choose the proper weight according to the actual demand. It is recommended to use a weight for the test sample that is half of the test sample’s weight. If the test result is less than 20% or more than 80% of the range, the result may be inaccurate. Replace more proper weight and choose the weight parameters.

Here is a brief introduction. For the detailed procedure, contact us. We will provide the operation manual for you.

Calibration

Parameter calibration.

Click this key on the menu page. Enter the correct password to jump to the instrument calibration page. Here, you can calibrate the instrument or set the gravity acceleration value. Before the calibration, install a test weight and a calibration weight. The calibration weight should be 50% of the range. There are two modes for error correction: single point mode and curve mode. In the first mode, a weight within 50% of the calibration coefficient is used. In the second, the interval method is adopted.

Operation calibration.

Pull up the pendulum to the upper limit. Do not put any objects on the clamp and tighten it to the closed state.

Install the proper test weights and calibration weights on the pendulum. Put them in the specified position and lock them tightly without loosening. Press the two Start keys simultaneously, and put down the pendulum.

Observe whether the calibration result is consistent with the calibration weights. If so, it’s completed; otherwise, repeat the steps if recalibration is required.

Note: Recalibrate it each time the machine is turned on or the weight is replaced. Ensure more accurate results.

Keep the environment ventilated, dry, and free of dust.

Perform routine cleaning on the instrument. Clean up the residual sample in the gripper. It’s advised to use a clean, soft-bristled brush to remove dust.

Add an appropriate amount of lubricant or grease every 3-6 months to the pendulum bearing.

Remove the weight when idle and stow it in a safe place. Avoid collisions, friction, or rust in case of any changes in the quality or centre of mass.

Install the weight in place and tighten the weight nut before it’s used.

Keep your hands or head away from the rotating handle when it’s working. Handles must clear all obstacles without making contact.

Before using the instrument, swing it several more times to zero it out since it has not been used for a long time.

Be sure to put the swinging device in the locked state first if it’s needed.

There is no strong electromagnetic interference in the surrounding area.

Regular maintenance is a must.