This article delves deep into the pivotal role that constant temperature and humidity chambers play in enhancing the quality standards of textile production processes.

From maintaining the integrity of delicate fibers to ensuring uniform dye absorption, the intricate dance between temperature and humidity profoundly influences every stage of textile manufacturing. Join us as we unravel the intricate relationship between climate control and textile excellence.

What are Constant Temperature and Humidity Chambers in Textile Manufacturing?

Constant temperature and humidity chambers stand as guardians of product integrity. But what exactly is a constant temperature and humidity chamber, and why is it indispensable in textile production? Let us unravel the mystery behind these essential items and explore their role in shaping the fabric of modern textile manufacturing.

At its core, a constant temperature and humidity chamber, often referred to simply as a climate chamber, is a specialized enclosure designed to precisely control and maintain specific temperature and humidity levels within a defined space. These chambers provide a controlled environment akin to the conditions found in nature or tailored to mimic the requirements of a particular manufacturing process. In the realm of textile manufacturing, where factors such as fiber stability, dye absorption, and moisture content can profoundly impact fabric quality, maintaining consistent climate conditions is paramount.

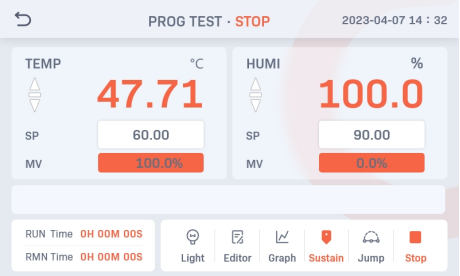

The functionality of a temperature and humidity-controlled box revolves around its ability to regulate both temperature and humidity levels with utmost precision. Temperature control ensures that the environment remains within a narrow range conducive to textile production, preventing fluctuations that could compromise product quality. Similarly, humidity control safeguards against moisture-related defects such as mold growth, fiber swelling, or dimensional instability, all of which can wreak havoc on textile products.

Within the confines of a temperature and humidity-controlled box, textile manufacturers have the flexibility to tailor climate conditions to suit their specific production needs. Whether it is conditioning yarns and fibers before weaving, setting dyes and finishes, or testing fabric performance under simulated environmental stresses, these chambers serve as versatile tools in the textile engineer’s arsenal.

However, the significance of constant temperature and humidity chambers extends beyond mere climate control. These chambers also play a crucial role in research and development endeavors, enabling textile scientists to explore the intricate interplay between environmental factors and fabric properties. By subjecting textiles to controlled environmental conditions, researchers can gain invaluable insights into material behavior, performance characteristics, and potential areas for innovation and improvement.

The design and construction of constant temperature and humidity chambers vary depending on the specific application and industry requirements. However, common features typically include insulated enclosures with tightly sealed doors to minimize heat exchange with the external environment, sophisticated temperature and humidity control systems equipped with sensors and actuators for precise regulation, and user-friendly interfaces for monitoring and adjusting chamber parameters.

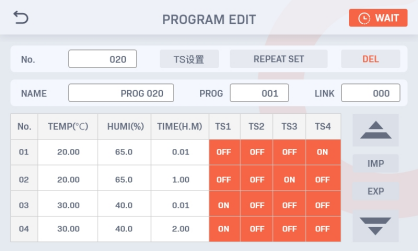

In addition to their primary function of climate control, constant temperature and humidity chambers may incorporate supplementary features to enhance their utility and convenience. These may include programmable control systems for creating custom temperature and humidity profiles, integrated safety mechanisms to prevent overheating or excessive humidity levels, and remote monitoring capabilities for real-time surveillance of chamber conditions.

In the bustling landscape of textile manufacturing, where precision and quality reign supreme, selecting the right humidity chamber can make all the difference. These chambers are instrumental in maintaining the ideal climate conditions necessary for consistent and high-quality fabric production. However, with a myriad of options available in the market, choosing the perfect chamber can be a daunting task. Fear not, for this comprehensive guide is here to illuminate the path toward selecting the ideal constant temperature and humidity chamber tailored to your textile manufacturing needs.

Understanding Your Requirements:

Before embarking on the journey of selecting a constantly controlled humidity chamber, it is imperative to gain a clear understanding of your specific requirements. Consider factors such as the volume of textiles to be processed, the desired temperature and humidity range, as well as any specific requirements unique to your manufacturing process. Are you working with delicate fibers that demand precise climate control, or are you aiming for high-volume production with consistent results? By elucidating your requirements upfront, you pave the way for a more informed decision-making process.

Evaluating Performance Metrics:

Once you have delineated your requirements, it is time to dive into the practical details of performance metrics. When evaluating constant temperature and humidity chambers, pay close attention to factors such as temperature uniformity, humidity control accuracy, and chamber stability over time. A chamber with excellent temperature and humidity uniformity ensures consistent results across the entire fabric batch, while precise humidity control safeguards against moisture-related defects. Additionally, consider the chamber’s reliability and durability, as these factors are pivotal in ensuring uninterrupted production.

Assessing Technological Capabilities:

In the ever-evolving landscape of textile manufacturing technology, constant temperature and humidity chambers are no exception. When selecting a stability chamber temperature and humidity, inquire about the technological capabilities that set it apart from the competition. Does it offer advanced features such as programmable temperature and humidity profiles, remote monitoring capabilities, or energy-efficient design? Technological advancements not only enhance operational efficiency but also future-proof your investment against evolving industry standards.

Ensuring Compliance and Certification:

Textile manufacturing is a highly regulated industry, with stringent quality standards and compliance requirements. Before finalizing your selection, ascertain that the constant temperature and humidity chamber meet relevant industry regulations and certifications. Look for certifications such as ISO 9001 for quality management systems and ISO 17025 for testing and calibration laboratories. Compliance with industry standards not only instills confidence in the chamber’s performance but also mitigates the risk of regulatory non-compliance down the line.

Considering Space and Integration:

In the fast-paced world of textile manufacturing, floor space is a precious commodity. When selecting an environmental chamber temperature humidity control, consider its footprint and integration feasibility within your existing production facility. Opt for a chamber that maximizes space efficiency without compromising on performance. Additionally, assess the chamber’s compatibility with other equipment and automation systems to ensure seamless integration into your manufacturing workflow.

Factoring in Total Cost of Ownership:

While upfront cost is undoubtedly a crucial consideration, it is essential to take a holistic view of the total cost of ownership (TCO) over the environmental chamber humidity chamber’s lifecycle. Beyond the initial purchase price, consider ongoing maintenance, calibration, and energy consumption costs. A chamber with lower TCO may prove to be a more cost-effective investment overall, providing superior performance and reliability without breaking the bank.

Seeking Expert Consultation:

Navigating the myriad options available in the market can be overwhelming, especially for those new to the world of constant temperature and humidity chambers. When in doubt, seek expert consultation from reputable suppliers and industry professionals. Experienced consultants can offer invaluable insights tailored to your specific needs, guiding you toward the optimal chamber solution for your textile manufacturing operation.

Deciphering the Cost Factors of Constant Temperature and Humidity Chambers

Constant temp humidity chambers are vital assets in textile manufacturing, but their price tags can vary significantly depending on several factors. Understanding the key determinants of a chamber’s price is essential for making informed purchasing decisions and optimizing return on investment. Let us delve into the intricate web of factors that influence the cost of these indispensable apparatuses.

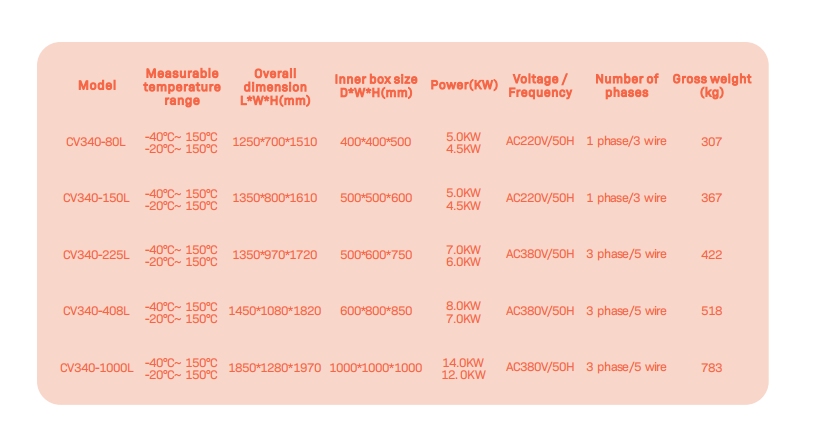

Size and Capacity: One of the most obvious factors influencing the price of a constant temperature and humidity chamber is its size and capacity. Larger chambers capable of accommodating larger batches of textiles or bulky equipment command higher price points due to the increased materials and construction costs involved.

Temperature and Humidity Control Precision: The level of precision in temperature and humidity control directly impacts the chamber’s price. Chambers equipped with advanced control systems capable of maintaining ultra-stable conditions with minimal deviations command a premium price due to the sophistication of their technology and engineering.

Construction Materials and Quality: The materials used in the construction of constant temp and humidity chambers play a significant role in determining their price. Chambers constructed with high-quality, durable materials such as stainless steel or reinforced plastics tend to be more expensive upfront but offer greater longevity and reliability, thereby reducing long-term maintenance costs.

Technological Features and Integration: Constant temperature and humidity chambers equipped with advanced technological features, such as programmable control systems, remote monitoring capabilities, or integration with other automation systems, typically come with higher price tags. These features enhance operational efficiency and convenience but contribute to the overall cost of the chamber.

Certifications and Compliance: Chambers that meet stringent industry standards and certifications, such as ISO 9001 for quality management systems or ISO 17025 for testing and calibration laboratories, may command higher prices due to the additional costs associated with compliance testing and certification processes.

Brand Reputation and Support Services: The reputation of the manufacturer and the availability of comprehensive support services can also influence the price of constant temperature and humidity chambers. Established brands known for their quality craftsmanship and reliable customer support may charge premium prices for their products, reflecting the value of their brand reputation.

Customization and Special Requirements: Chambers designed to meet specific customization requirements or equipped with specific features tailored to unique manufacturing processes may incur additional costs. Customization entails engineering design, prototyping, and testing, all of which contribute to the overall price of the chamber.

Energy Efficiency and Operating Costs: While energy-efficient chambers may come with a higher initial price tag, they offer long-term cost savings through reduced energy consumption and operating costs. Chambers equipped with energy-saving features such as insulation enhancements or efficient heating and cooling systems may justify their higher upfront costs over time.

Top 10 Brands in the Constant Temperature and Humidity Chamber Industry

In the competitive landscape of constant temp and humidity chambers, several brands have established themselves as leaders in innovation, reliability, and quality craftsmanship. Let us explore the top 10 brands that stand out in the field of climate control solutions for textile manufacturing and beyond:

ESPEC North America Inc.: With a legacy spanning over half a century, ESPEC North America Inc. is renowned for its innovative environmental testing chambers, including constant temperature and humidity chambers. Their chambers are celebrated for their precision control, durability, and versatility across various industries, including textiles.

Thermo Fisher Scientific: Thermo Fisher Scientific is a global leader in scientific instrumentation, offering a wide range of laboratory equipment, including constant temp and humidity chambers . Their chambers are lauded for their advanced technology, reliability, and robust construction, making them a trusted choice for textile manufacturers worldwide.

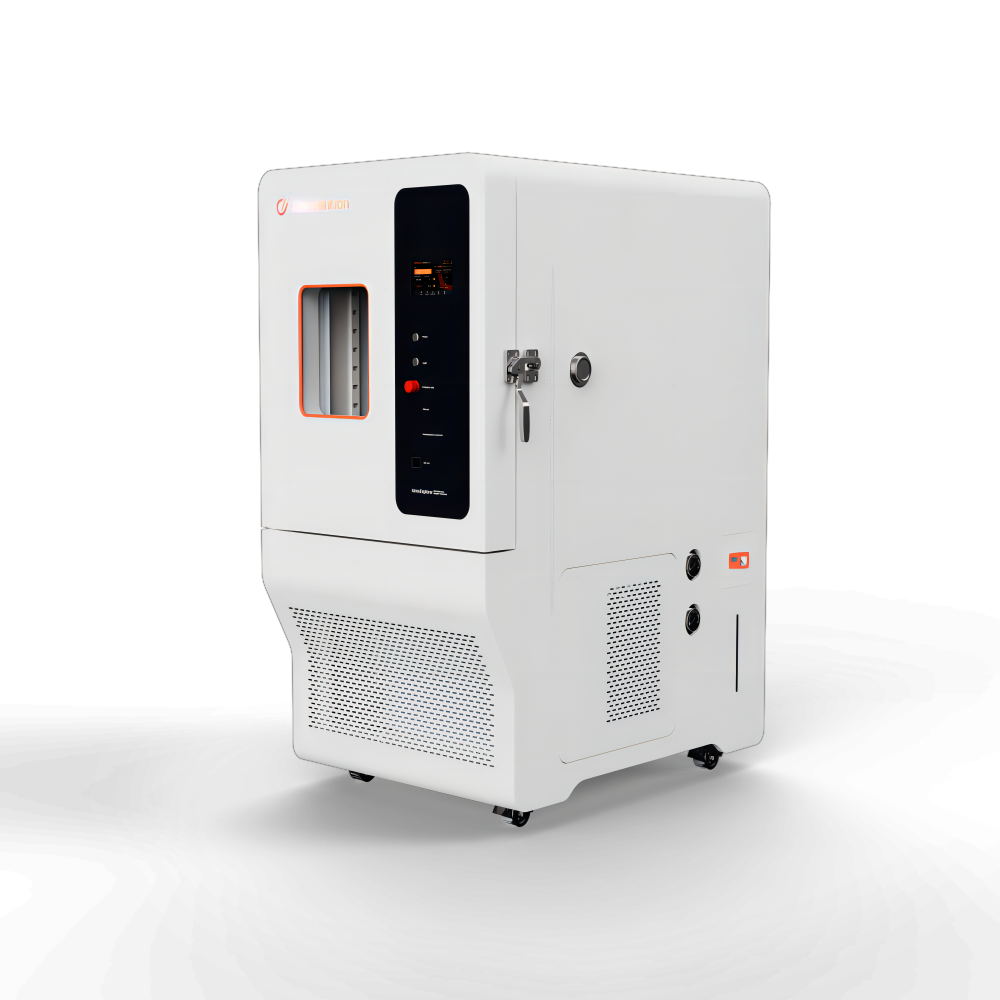

ChiuVention: Designed in Germany and manufactured in China, the AtmoExplorer Temperature and Humidity Chambers are sold in 42 countries worldwide and this machine has a very wide control scope in temperature and humidity so it can be more practical.

Binder GmbH: Binder GmbH is synonymous with excellence in the field of climate simulation chambers, including constant temperature and humidity chambers. Known for their German engineering prowess, Binder chambers boast superior performance, precision control, and customizable features tailored to specific industry needs.

Memmert GmbH + Co. KG: Memmert GmbH + Co. KG is a renowned manufacturer of precision temperature control equipment, including constant climate chambers. Their chambers are esteemed for their impeccable temperature and humidity control, energy efficiency, and user-friendly design, making them a preferred choice for textile research and development.

CSZ Products, Inc.: CSZ Products, Inc. specializes in temp and humidity chambers designed to meet the rigorous demands of various industries, including textiles. Their constant temperature and humidity chambers are prized for their reliability, durability, and advanced control features, making them ideal for critical manufacturing processes.

Yamato Scientific Co., Ltd.: Yamato Scientific Co., Ltd. is a leading Japanese manufacturer of scientific and laboratory equipment, including temp and humidity chambers. Renowned for their precision engineering and technological innovation, Yamato Chambers delivers unparalleled performance and reliability in textile manufacturing applications.

Angelantoni Test Technologies S.R.l.: Angelantoni Test Technologies S.R.l. is a prominent supplier of environmental test chambers, offering a comprehensive range of solutions, including temp and humidity chambers. Their chambers are characterized by their robust construction, precise control, and customizable features tailored to specific customer requirements.

Associated Environmental Systems (AES): Associated Environmental Systems (AES) specializes in the design and manufacture of environmental test chambers for a wide range of applications, including textiles. Their constant temperature and humidity chambers are revered for their quality craftsmanship, innovative features, and exceptional performance in demanding manufacturing environments.

Weiss Technik North America, Inc.: Weiss Technik North America, Inc. is a leading provider of environmental testing solutions, offering an extensive portfolio of temp and humidity chambers, including constant climate chambers. Renowned for their German engineering heritage, Weiss Technik chambers deliver unmatched reliability, precision control, and versatility in textile manufacturing settings.

Key Considerations for Using Constant Temperature and Humidity Chambers Across Industries and Materials

Utilizing constant temperature and humidity chambers across diverse industries and materials requires careful consideration of several factors to ensure optimal performance and reliability. Here are essential aspects to keep in mind when employing these chambers in different industrial settings or with various materials:

Temperature and Humidity Range: Understand the specific temperature and humidity requirements of the materials or processes involved in your industry.

Varied materials may have unique sensitivities to temperature and humidity, necessitating precise control within narrow ranges to prevent damage or degradation.

Material Compatibility: Consider the compatibility of the temp and humidity chambers with the materials being tested or processed. Certain materials may react adversely to specific chamber materials or environmental conditions, leading to unintended consequences such as corrosion, degradation, or contamination.

Regulatory Compliance: Ensure that the constant temperature and humidity chamber meets relevant industry standards and regulatory requirements for your specific application or industry. Compliance with standards such as ISO, ASTM, or regulatory agencies ensures that your testing or manufacturing processes adhere to quality and safety protocols.

Sample Size and Configuration: Consider the size, shape, and configuration of the samples or materials being tested or processed within the chamber. Optimize chamber setup and layout to accommodate varying sample sizes, shapes, or quantities while ensuring uniform exposure to temperature and humidity conditions.

Testing Protocols and Procedures: Develop and adhere to standardized testing protocols and procedures tailored to your industry or material requirements. Establish clear guidelines for sample preparation, testing duration, data collection, and analysis to ensure consistency and reproducibility of results across different testing scenarios.

Monitoring and Control Systems: Implement robust monitoring and control systems within the temp and humidity chambers to track and maintain desired environmental conditions accurately. Utilize advanced sensors, data loggers, and automated control algorithms to ensure precise control and real-time monitoring of chamber parameters.

Calibration and Maintenance: Regularly calibrate and maintain the constant temp and humidity chambers to ensure accurate performance and reliability over time. Schedule routine maintenance checks, calibration procedures, and quality assurance measures to identify and address any deviations or malfunctions promptly.

Material Handling and Safety: Establish proper material handling procedures and safety protocols to minimize risks associated with the operation of constant temp and humidity chambers. Ensure adequate ventilation, safety interlocks, and emergency shutdown procedures to protect personnel and equipment from potential hazards.

Data Management and Documentation: Implement robust data management and documentation practices to record and archive testing or manufacturing data generated within the constant temperature and humidity chamber. Maintain detailed records of experimental conditions, sample characteristics, and test results for traceability, analysis, and future reference.

Adaptability and Flexibility: Design constant temperature and humidity chamber setups that offer adaptability and flexibility to accommodate changing industry requirements, materials, or testing protocols. Invest in modular chamber configurations, interchangeable accessories, or software updates to future-proof your testing or manufacturing capabilities.

Ensuring Reliability in Constant Temperature and Humidity Chamber Tests

Achieving reliable test results in constant temp and humidity chambers is paramount for making informed decisions in various industries and applications. Here are essential strategies to enhance the reliability of tests conducted within these chambers:

Calibration and Validation: Regularly calibrate and validate the constant temperature and humidity chamber to ensure accurate and consistent performance. Use traceable standards and procedures to verify temperature and humidity sensors, controllers, and other critical components.

Standardized Procedures: Develop standardized testing procedures and protocols tailored to your specific industry or application. Clearly define test parameters, sample preparation methods, testing durations, and data collection protocols to ensure consistency and reproducibility of results.

Sample Preparation: Follow meticulous sample preparation procedures to minimize variability and ensure uniformity across test specimens. Standardize sample size, shape, orientation, and placement within the chamber to reduce experimental errors and enhance the comparability of results.

Environmental Monitoring: Implement robust environmental monitoring systems within the chamber to track temperature and humidity conditions accurately. Utilize calibrated sensors, data loggers, and automated control algorithms to maintain desired environmental setpoints and detect deviations promptly.

Quality Control Checks: Incorporate quality control checks throughout the testing process to identify and mitigate potential sources of error or variability. Conduct periodic checks of chamber performance, sample integrity, and data consistency to maintain confidence in test results.

Data Analysis and Interpretation: Employ rigorous data analysis and interpretation techniques to extract meaningful insights from test results. Use statistical methods, trend analysis, and data visualization tools to identify patterns, outliers, or trends that may influence the reliability of test outcomes.

Peer Review and Collaboration: Foster a culture of peer review and collaboration within your organization or research community to validate test methodologies, share best practices, and ensure the robustness of experimental designs. Solicit feedback from colleagues, experts, or external stakeholders to improve the reliability of tests conducted in constant temperature and humidity chambers.

Documentation and Reporting: Maintain detailed documentation of test procedures, experimental conditions, sample characteristics, and results in comprehensive test reports. Document any deviations, anomalies, or unexpected observations encountered during testing to facilitate troubleshooting and future analysis.

Risk Management: Identify and mitigate potential sources of risk or uncertainty that may impact the reliability of test results. Conduct risk assessments to identify critical control points, failure modes, and mitigation strategies to minimize the likelihood of errors or biases in test outcomes.

Continuous Improvement: Embrace a culture of continuous improvement to enhance the reliability of tests conducted in constant temperature and humidity chambers. Solicit feedback from stakeholders, monitor performance metrics, and implement corrective actions or process improvements to optimize testing practices over time.

Conclusion

Throughout this article, we have explored the intricacies of selecting, using, and optimizing constant temp and humidity chambers to meet the unique needs and challenges in the textile manufacturing industry. We have delved into the key considerations for choosing the ideal chamber, navigating the selection process, and enhancing the reliability of tests conducted within these chambers.

From defining requirements and evaluating performance metrics to considering technological features and compliance requirements, each step in the process is essential for ensuring the successful integration of constant temperature and humidity chambers into manufacturing and research workflows. By following best practices, leveraging advanced technologies, and fostering a culture of continuous improvement, organizations can maximize the value and utility of these chambers, driving quality, efficiency, and innovation in their respective fields.

As technology advances and industry standards evolve, the role of temp and humidity chambers will continue to expand, enabling discoveries, breakthroughs, and advancements across a wide range of disciplines.

By harnessing the power of these chambers and embracing the principles of precision, reliability, and collaboration, we can unlock new frontiers of knowledge and propel human progress forward into the future.

For more information on textile testing methods/standards

or temperature and humidity chamber price, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: [email protected]